Venerupis philippinarum compound feed

A compound feed and clam technology, which is applied in the field of clam compound feed, can solve problems such as low production efficiency, insufficient natural bait, and slow growth rate, and achieve the goals of improving environmental protection, good palatability and food attraction, and increasing growth rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

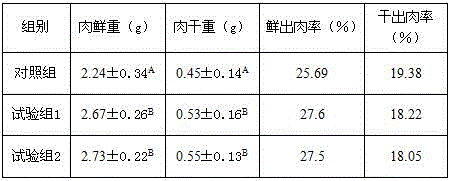

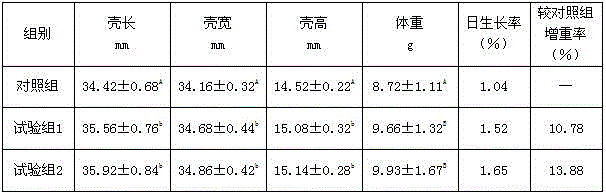

Examples

Embodiment 1

[0039] This embodiment is illustrated by taking the production of clam compound feed in Hubei Jingu Pharmaceutical Co., Ltd. as an example.

[0040] A clam compound feed of the present invention is composed of the following raw materials in parts by weight:

[0041] Expanded soybean meal 42kg Corn flour 20kg

[0042] Rapeseed Meal 20kg Yeast Powder 5kg

[0043] Scallop Powder 12kg Multivitamins 0.3kg

[0044]Choline chloride 0.2kg Chenpi powder 0.3kg.

[0045] During preparation, the above-mentioned raw materials are pulverized and passed through a 120-mesh sieve, and then mixed uniformly by a twin-shaft paddle mixer to obtain the product.

[0046] When in use, feed 0.5 to 1 kg of the compound feed of this embodiment per 100 kg of clams every day, and directly and evenly sprinkle it on the clams when throwing in.

[0047] The compound vitamins selected in the formula of the present invention are prepared according to the enterprise standard Q / HJG016-2012 of Hubei Jingu Pha...

Embodiment 2

[0060] A clam compound feed is composed of the following raw materials in parts by weight:

[0061] Expanded soybean meal 35kg Corn flour 25kg

[0062] Rapeseed Meal 23kg Yeast Powder 4kg

[0063] Scallop Powder 10kg Multivitamins 0.3kg

[0064] Choline chloride 0.2kg Chenpi powder 0.2kg.

[0065] The preparation method is the same as in Example 1.

Embodiment 3

[0067] A clam compound feed is composed of the following raw materials in parts by weight:

[0068] Expanded soybean meal 45kg Corn flour 20kg

[0069] Rapeseed Meal 18kg Yeast Powder 5kg

[0070] Scallop Powder 14kg Multivitamins 0.2kg

[0071] Choline chloride 0.3kg Chenpi powder 0.3kg;

[0072] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com