SNCR (selective non-catalytic reduction) flue gas denitrification method and device utilizing organic/ammonia nitrogen waste liquid

A technology of ammonia nitrogen and waste liquid, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high denitrification operation cost and waste of agricultural chemical fertilizer resources, and achieve reduction of denitrification operation cost, saving process and cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A SNCR flue gas denitrification method utilizing organic / ammonia nitrogen waste liquid, comprising the step of injecting organic / ammonia nitrogen waste liquid into the high temperature zone of the cement kiln decomposition furnace; Areas in the range of 980°C. Wherein, the high temperature zone refers to the zone where the temperature in the calciner of the cement kiln is preferably in the range of 900-950°C. Control the volume ratio of the injection amount of the organic / ammonia nitrogen waste liquid to the amount of flue gas in the cement kiln decomposition furnace to be 1 × 10 -6 -1×10 -5 . Specifically, a spray gun is used to spray the organic / ammonia nitrogen waste liquid into the high temperature zone of the cement kiln decomposition furnace, the inlet pressure of the organic / ammonia nitrogen waste liquid entering the spray gun is controlled to be 0.35-0.45MPa, and the compressed air pressure entering the spray gun is 0.40-0.50MPa.

[0036] In Example 1, the or...

Embodiment 2

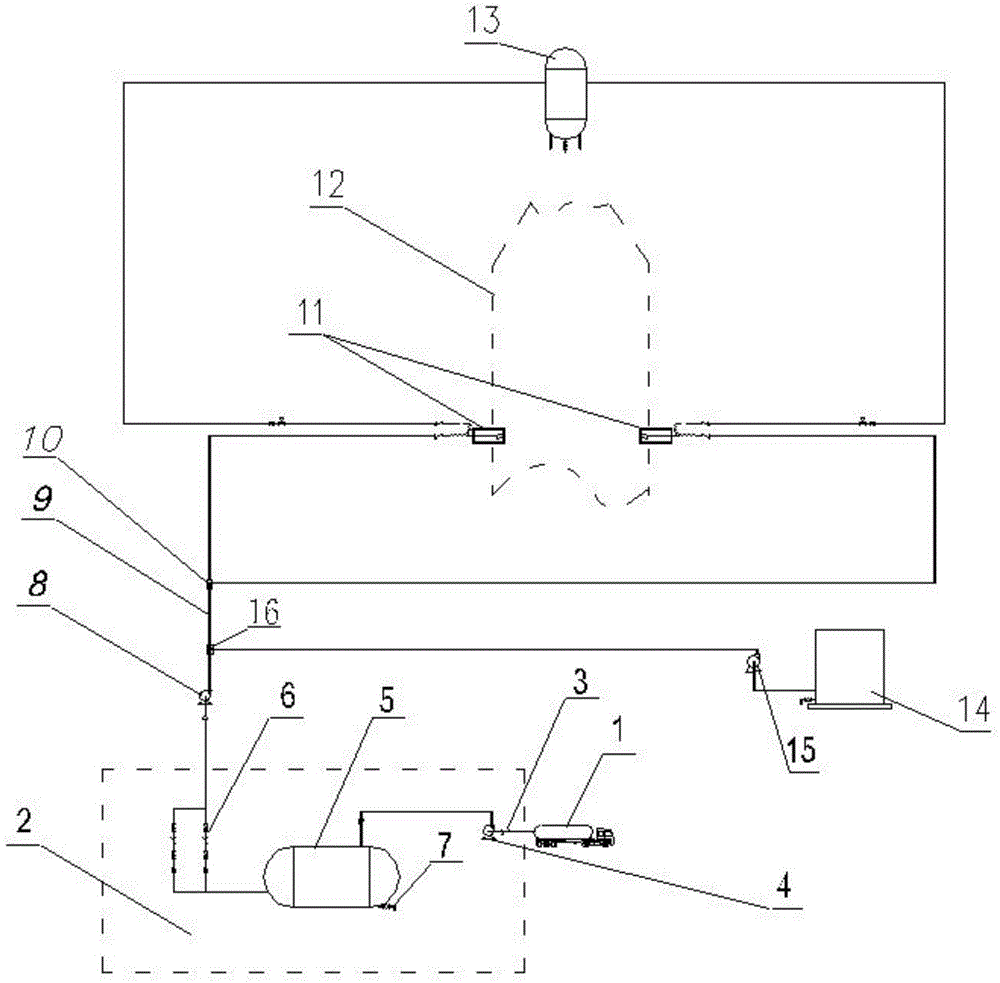

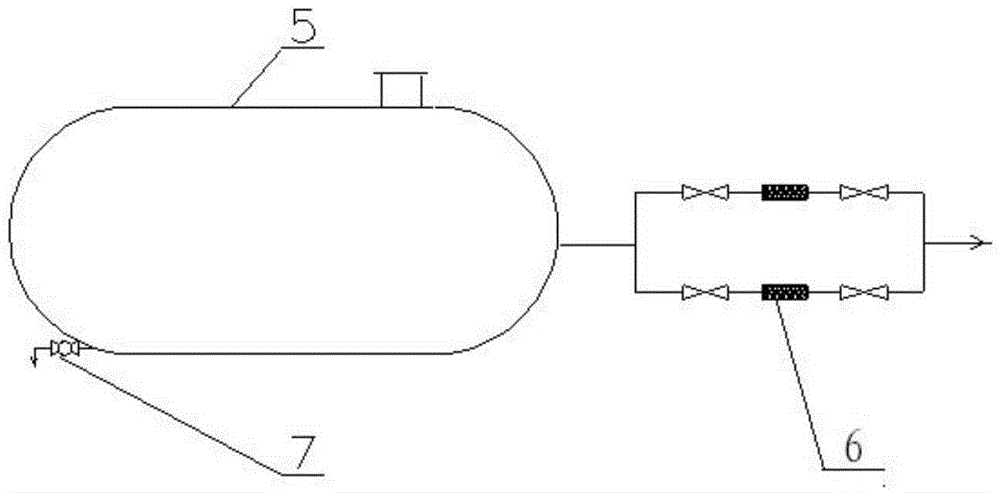

[0040] combine figure 1 As shown, the denitrification device that completes the SNCR flue gas denitration method of the above-mentioned embodiment 1 using organic / ammonia nitrogen waste liquid includes a reductant storage tank 5, a filter group 6, a booster pump 8, a reductant distributor 10, and a mist A spray gun 11, a reductant adjustment tank 14 and a mixer 16 (preferably a static mixer), the outlet of the reductant storage tank 5 is connected to the inlet of the filter group 6, and the outlet of the filter group 6 is connected to the inlet of the filter group 6 The inlet of the booster pump 8 is connected, the outlet of the booster pump 8 is connected to the inlet of the reducing agent distributor 10 through the reducing agent pipeline 9, each outlet of the reducing agent distributor 10 is connected to the atomizing spray gun 11 The inlet connection of the atomizing spray gun 11 is set at the reducing agent inlet position of the cement kiln calciner 12; On the side wall ...

Embodiment 3

[0049] Using the denitrification device of Example 2, the SNCR flue gas denitrification method using organic / ammonia nitrogen waste liquid in Example 1 was used to conduct experiments to test the denitrification efficiency. The details are as follows: the flue gas volume is 3500Nm 3 The combustion system of / h simulates the cement kiln decomposition furnace to carry out the denitrification test of waste water SNCR flue gas. The organic waste water is acrylic acid chemical waste water, its total organic carbon content is 4.09%, and its total carbon content is 4.17%. Flue gas flow rate is 3510m 3 / h, the NOx concentration is 68ppm. Acrylic chemical organic wastewater is sprayed into the 880°C high temperature zone of the cement kiln decomposition furnace, and the amount of acrylic chemical organic wastewater is 5.5L / h. After flue gas denitrification, the NOx concentration is 38ppm, and the denitrification efficiency reaches 45%.

[0050] In this embodiment 3, the volume ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com