Device and method for realizing splitting of micro-droplets in micro-channel under assistance of surface acoustic waves

A surface acoustic wave and microchannel technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the complex design of focusing interdigital transducers, the difficulty of applying piezoelectric microfluidic systems, Lithium oxide substrate fragmentation and other problems, to achieve the effect of simple structure, transportation, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

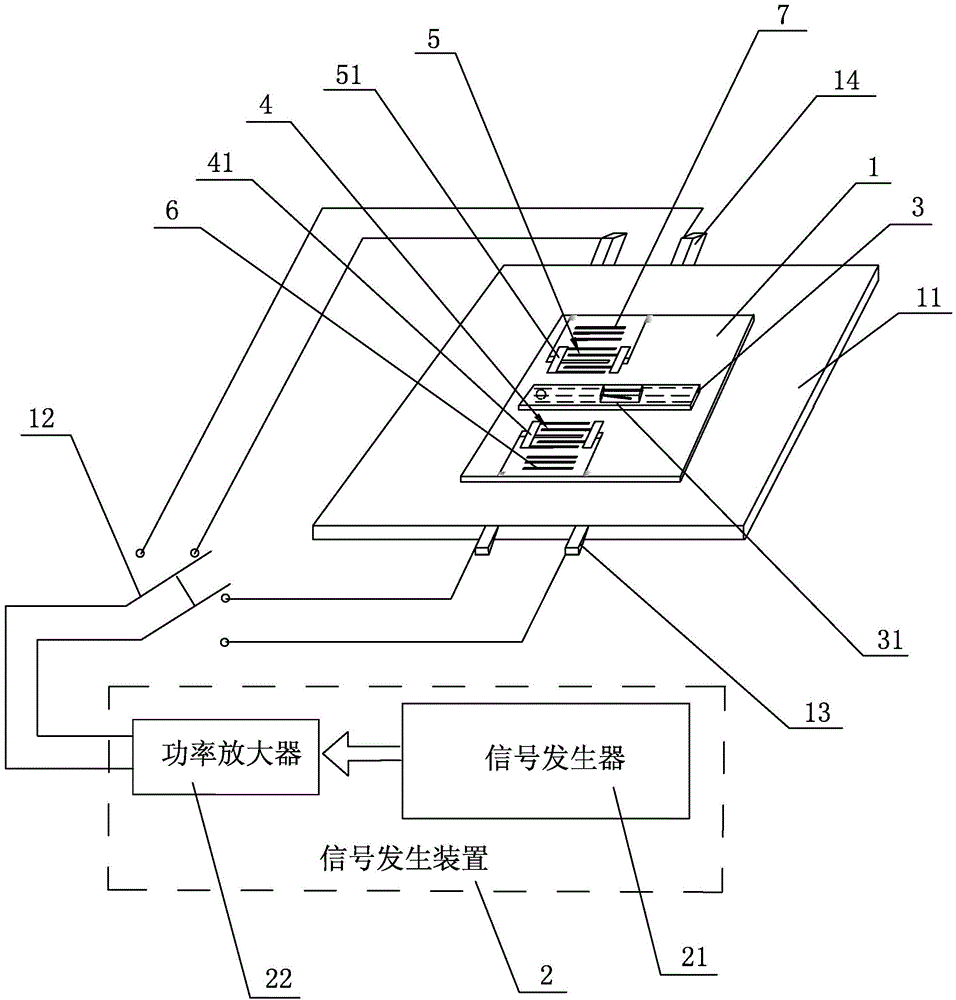

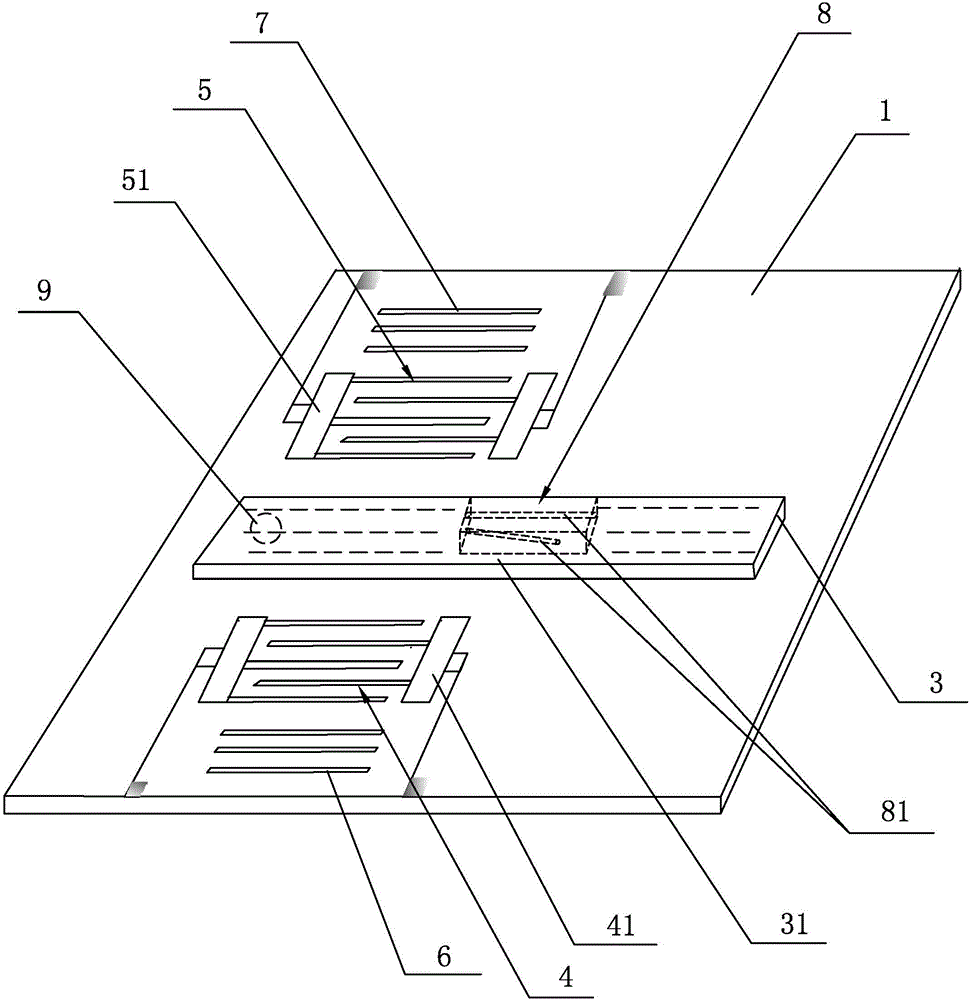

Embodiment 1

[0034] A surface acoustic wave-assisted device for splitting micro-droplets in a microchannel proposed in this embodiment, as shown in the figure, includes a piezoelectric substrate 1 and a signal generating device 2 for generating RF electrical signals. The upper surface of the sheet 1 is the working surface, and the working surface of the piezoelectric substrate 1 is provided with microchannels 3 for transporting digital micro-droplets 9, which are respectively connected with the signal generating device 2 and are used to excite the splitting of the surface acoustic wave. Unweighted IDT 4 and non-split unweighted IDT 5, a first reflective grating 6 for reducing the power of the RF electrical signal loaded on the split unweighted IDT 4, The second reflection grid 7 for reducing the power of the RF electrical signal loaded on the unweighted interdigital transducer 5 for splitting, the unweighted interdigital transducer 4 for splitting, and the unweighted interdigital transducer...

Embodiment 2

[0041] This embodiment proposes a method corresponding to the device for assisting the splitting of micro-droplets in a microchannel given in Embodiment 1, which includes the following steps:

[0042] ①Connect the signal generator and power amplifier of the signal generating device, connect the power amplifier and switch, connect the bus bar and the first lead pin of the unweighted IDT for splitting, and connect the unweighted IDT for non-split of the bus bar with the second lead pin.

[0043] ② Place the digital micro-droplet to be split in the front part of the microchannel, and make the digital micro-droplet to be split on the acoustic transmission path of the surface acoustic wave excited by the unweighted interdigital transducer for splitting.

[0044] ③ Make the switch connect the power amplifier and the first lead pin, start the signal generator and the power amplifier, and utilize the existing sample injector to inject the sample immiscible with the aqueous phase fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com