Reduction system for vat dye or sulfur dyestuff dyeing and reduction method

A technology of sulfur dyes and dyes, which is applied in the field of dyeing and finishing, can solve the problems of decreased active ingredients, decreased strength, and large acid consumption, and achieves the effects of reducing treatment costs, improving stability, and good color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: indigo dyed cotton

[0037] (1) Traditional hydrosulfite-caustic soda reduction

[0038] According to the prescription of indigo 5% (o.w.f.), hydrosulfite 15g / L, and caustic soda 33.7g / L, prepare 100ml reduced leucochrome solution and heat it at 80°C for 10min.

[0039] (2) TD-trisodium phosphate reduction

[0040] According to the prescription of thiourea dioxide 0.2mol / L, trisodium phosphate 0.4mol / L, and indigo 5% (o.w.f.), prepare 100ml reduced leucochrome solution and heat it at 80°C for 10min.

[0041] (3) TD-trisodium phosphate-sodium carbonate reduction

[0042] According to the prescription of thiourea dioxide 0.2mol / L, trisodium phosphate 0.2mol / L, sodium carbonate 0.05mol / L, and indigo 5% (o.w.f.), prepare 100ml reduced leucochrome solution and heat it at 80°C for 10min.

[0043] (4) TD-trisodium phosphate-sodium carbonate-sodium silicate reduction

[0044] Make 100ml reduced leucosome solution according to the prescription of thiourea dioxi...

Embodiment 2

[0050] Embodiment 2: Viscose dyed with reduced golden yellow GK

[0051] (1) Traditional hydrosulfite-caustic soda reduction

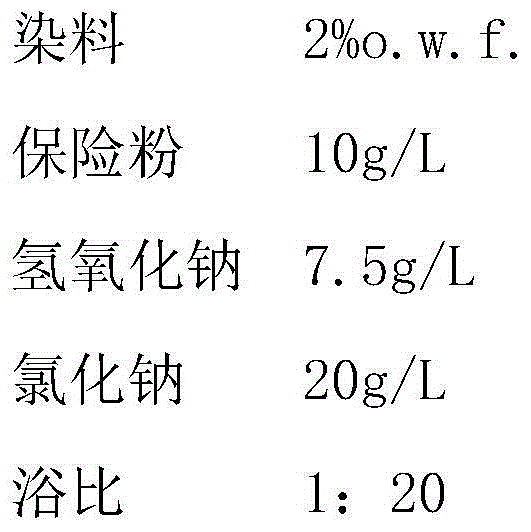

[0052] prescription

[0053]

[0054] After dissolving the dye with a small amount of water, add 2 / 3 of sodium hydroxide and hydrosulfite, add water to 1 / 3 of the total water, keep warm at 50°C for 15 minutes, add the remaining 1 / 3 of sodium hydroxide and hydrosulfite and 2 / 3 of water is made into leuco body solution.

[0055] (2) TD-sodium silicate reduction

[0056] According to the prescription of 0.18mol / L thiourea dioxide, 0.4mol / L sodium silicate, and reduced golden yellow GK 2% (o.w.f.), 120ml reduced leucochrome solution was prepared and heated at 55°C for 10min.

[0057] (3) TD-sodium carbonate-sodium silicate reduction

[0058] According to the prescription of 0.18 mol / L thiourea dioxide, 0.2 mol / L sodium carbonate, 0.1 mol / L sodium silicate, and reduced golden yellow GK 2% (o.w.f.), 120 ml reduced leucochrome solution was prepared and...

Embodiment 3

[0065] Embodiment 3: Sulfurized light yellow G dyed cotton

[0066] (1) Traditional alkali sulfide reduction

[0067] According to the prescription of sodium sulfide (sodium sulfide) 8% (o.w.f.), sulfide yellow G 4% (o.w.f.), prepare 120ml reduced leucosome solution, and heat it at 90°C for 10min.

[0068] (2) TD-sodium carbonate reduction

[0069] According to the prescription of 0.02 mol / L thiourea dioxide, 0.6 mol / L sodium carbonate, and 4% (o.w.f.) sulfide yellow G, prepare 120ml reduced leuco solution, and heat it at 80°C for 10 minutes.

[0070] (3) TD-trisodium phosphate-sodium carbonate method

[0071] According to the prescription of 0.02 mol / L thiourea dioxide, 0.3 mol / L trisodium phosphate, 0.1 mol / L sodium carbonate, and 4% (o.w.f.) of sulfur yellow G, prepare 120ml reduced leucochrome solution and heat it at 80°C for 10 minutes.

[0072] (4) TD-trisodium phosphate-sodium carbonate-sodium silicate method

[0073] Press thiourea dioxide 0.02mol / L, trisodium phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com