Filling mining method for slant middle-thick ore body

A filling mining and thick ore body technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of complicated mining process, poor safety of stope operation, poor adaptability of ore body, etc., to avoid the safety of stope operation Sexual issues, the effect of safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

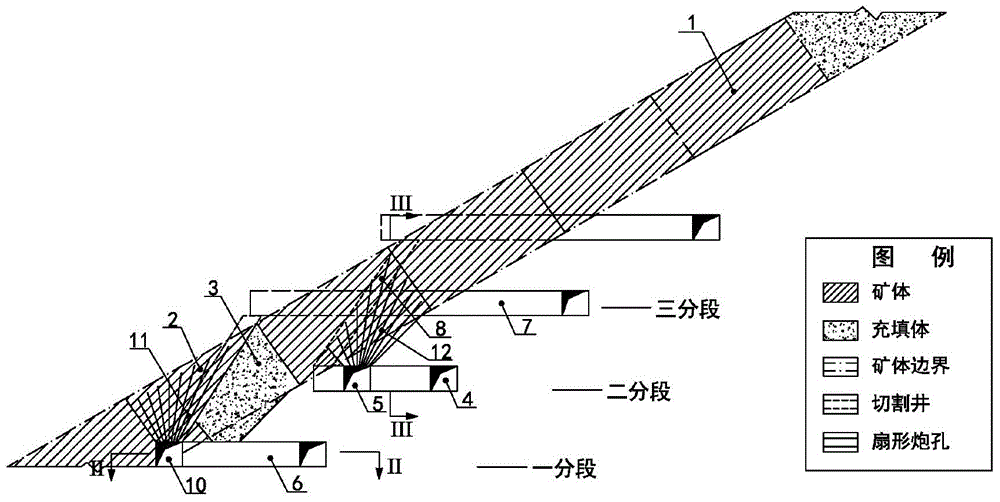

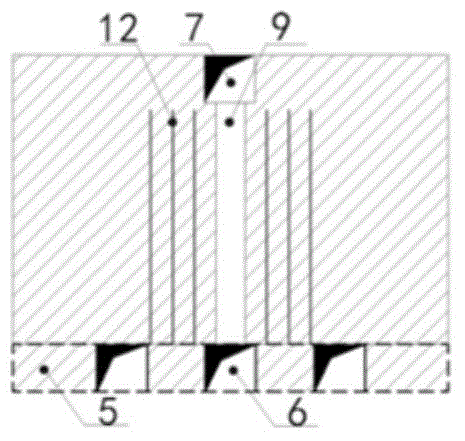

[0025] A filling mining method for inclined medium-thick ore bodies, the specific implementation process is as follows Figure 1~Figure 3 As shown, the stage height is set to 60m, the section height is 10-30m, and a mine room is divided every 30-40m along the direction of the ore body. The height of the mine room is the height of two sections, and the width is the full thickness of the ore body. Divide the mine house into two mining sections, the upper section (2) and the lower section (3), according to the connection line between the apex of the upper wall and the lower point of the lower wall. The lower section (3) is mined first and then the upper section ( 2).

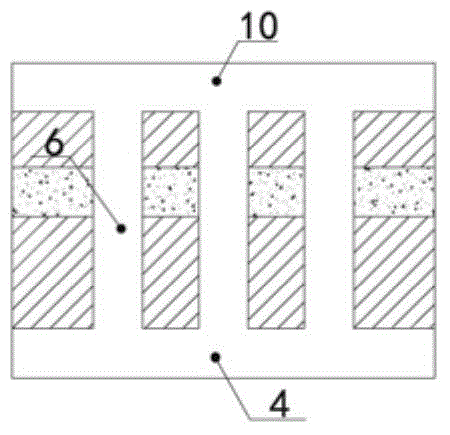

[0026] The next stope (3) mining process: At a position 15-20m away from the footwall of the ore body, along the direction of the ore body, construct a sub-vein transportation drift (4), and at a distance of 7-9m from the ore body footwall, construct parallel to the sub-vein transportation Segmented rock-drillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com