Method for producing sophorose from sophorolipids

A technology of sophorolipids and sophorose, applied in the field of expression solutions, can solve the problem that sophorose cannot be used on an industrial scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

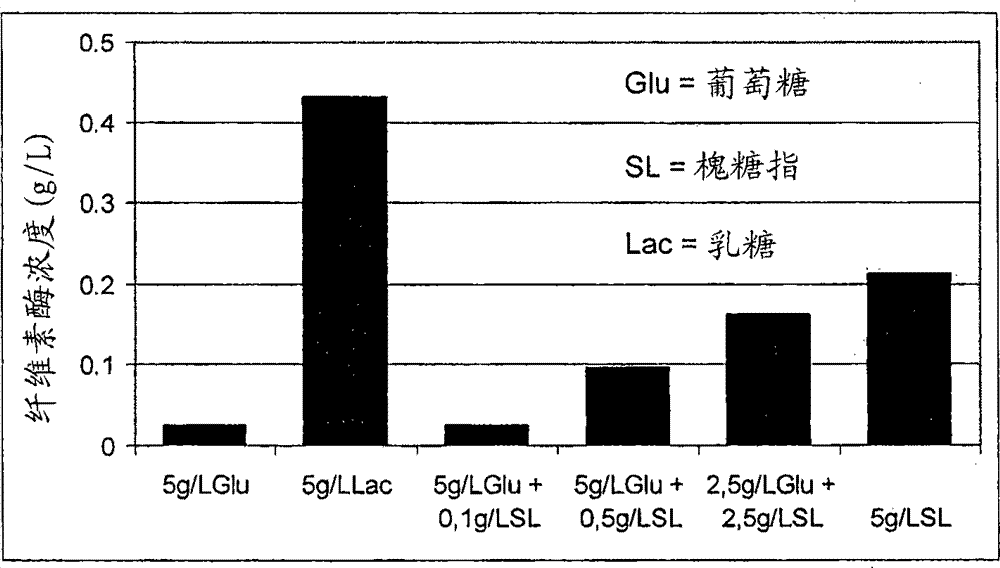

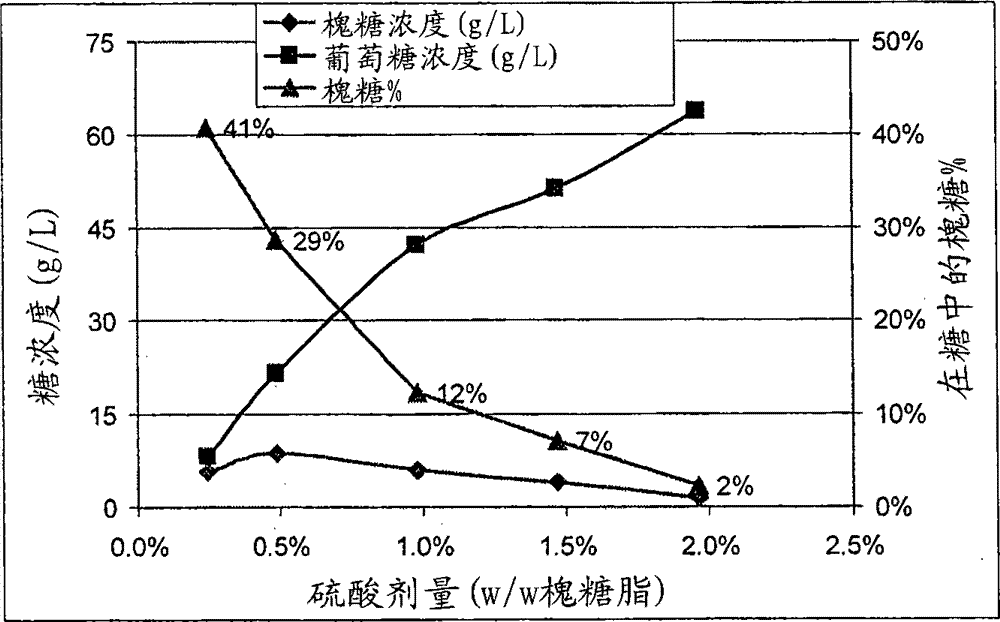

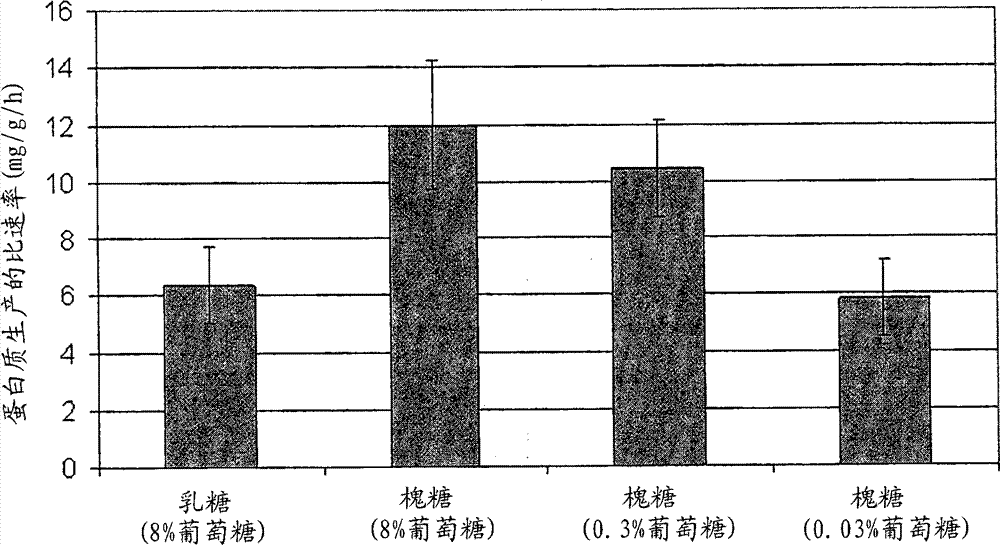

[0024] The present invention describes the conditions for carrying out the acid hydrolysis with the aim of producing sophorose and avoiding the complete hydrolysis of the sophorolipid which would lead to the release of two glucose units per molecule of the sophorolipid.

[0025] Under the conditions described below, hydrolysis can be used to preferentially break the glycosidic bond between the sophorose and the aliphatic chain, which leads to the release of the sophorose. However inevitably and to a greater or lesser extent depending on the operating conditions, the released sophorose may itself also be hydrolyzed into two glucose units.

[0026] In practice, an aqueous solution of sophorolipids is first provided. The sophorolipid concentration of the aqueous solution is usually 2-800 g / L, preferably 100-400 g / L. Preferably, the sophorolipids will be used in the acid form and not in the lactone form. This acid form can be obtained by optimizing the fermentation conditions du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com