Warning mechanism, chain conveying system using warning mechanism and tobacco cutter

An alarm switch and alarm triggering technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as time-consuming, wire cutter shutdown, and online product quality affecting the effective operation rate of the equipment. The effect of reducing the occupied space, ensuring continuous production, ensuring the effective operation rate of equipment and online product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

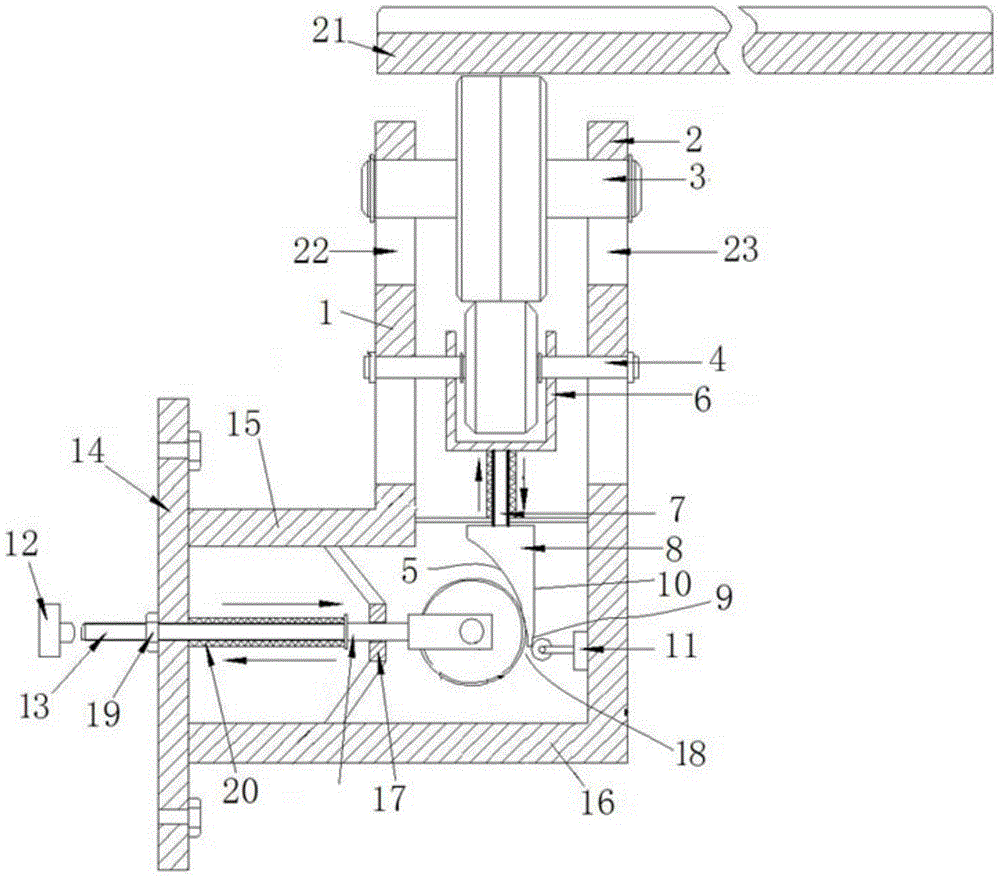

[0036] The present invention provides an embodiment 1 of an alarm mechanism: an alarm mechanism includes a mounting frame, and the mounting frame is provided with a stop switch for being triggered by the lower chain segment when the lower chain segment sags to a limit value, and the alarm mechanism also includes The alarm switch is used to be triggered before the stop switch before the lower chain link sags to the limit value. The alarm switch includes an alarm position switch 11 and a first alarm that is electrically connected with the alarm position switch, and the shutdown switch includes a shutdown position switch 12 and a second alarm and a controller that are electrically connected with the shutdown position switch.

[0037] The alarm mechanism also includes a transmission rod floating up and down on the installation frame, which is used to be indirectly pushed by the lower chain segment and move downward when the lower chain segment sags, so as to realize the lower chain...

Embodiment 2

[0059] At the same time, the present invention also provides Embodiment 2 of an alarm mechanism: the difference between this embodiment and Embodiment 1 is that in other embodiments, the above-mentioned transmission rod can also be a rod-shaped axis extending in the up-down direction. Structure, the right side of the transmission rod includes an inclined section with low left and high right and a vertical section extending up and down above the inclined section. Both ends are push-fitted with the right side of the transmission rod.

[0060] In other embodiments, the alarm switch and the shutdown switch can also be set up and down and are all located below the lower chain segments.

[0061] In other embodiments, the upper and lower push rollers can also be guided and moved up and down by other structural forms and assembled on the mounting frame. As the above push rollers are used as an example to illustrate, the upper push rollers are thick in the middle and have two ends. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com