A treatment method for high-concentration printing and dyeing desizing wastewater

A technology for desizing wastewater and treatment methods, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of difficult to form sedimentation activated sludge, low COD removal rate, Poor degradability and other problems, to achieve the effect of simple structure, low infrastructure cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

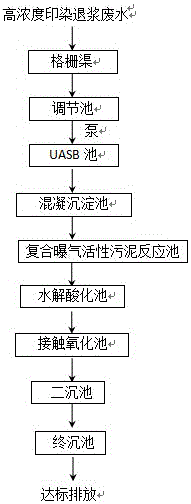

[0025] Such as figure 1 Shown: the method of the present invention can ensure that the treated effluent reaches the standard stably, and has been successfully operated on many engineering examples. The specific process is as follows:

[0026] (a) After the wastewater passes through the grid, part of the suspended solids is removed and enters the regulating tank, and then enters the forced circulation UASB tank for anaerobic biological treatment. The sewage enters evenly from the bottom of the UASB reactor through the water distribution system, and flows upward through the reaction zone into the gas, solid and liquid separation zone, and finally into the sedimentation zone on the upper part of the upflow anaerobic sludge bed reactor UASB; The biogas is discharged from the reactor through the pipeline through the gas collection chamber.

[0027] (b) The wastewater after UASB anaerobic treatment enters the coagulation sedimentation tank. The specific treatment steps are: the wa...

Embodiment 2

[0032] (a) After the wastewater passes through the grid, part of the suspended solids is removed and enters the regulating tank, and then enters the forced circulation UASB tank for anaerobic biological treatment. The sewage enters evenly from the bottom of the UASB reactor through the water distribution system, and flows upward through the reaction zone into the gas, solid and liquid separation zone, and finally into the sedimentation zone on the upper part of the upflow anaerobic sludge bed reactor UASB; The biogas is discharged from the reactor through the pipeline through the gas collection chamber.

[0033] (b) The wastewater after UASB anaerobic treatment enters the coagulation sedimentation tank. The specific treatment steps are: the wastewater first enters the UASB for anaerobic biological treatment, which changes the properties of suspended solids in the wastewater, facilitates physical and chemical precipitation, and more effectively removes pollution in the wastewate...

Embodiment 3

[0038](a) After the wastewater passes through the grid, part of the suspended solids is removed and enters the regulating tank, and then enters the forced circulation UASB tank for anaerobic biological treatment. The sewage enters evenly from the bottom of the UASB reactor through the water distribution system, and flows upward through the reaction zone into the gas, solid and liquid separation zone, and finally into the sedimentation zone on the upper part of the upflow anaerobic sludge bed reactor UASB; The biogas is discharged from the reactor through the pipeline through the gas collection chamber.

[0039] (b) The wastewater after UASB anaerobic treatment enters the coagulation sedimentation tank. The specific treatment steps are: the wastewater first enters the UASB for anaerobic biological treatment, which changes the properties of suspended solids in the wastewater, facilitates physical and chemical precipitation, and more effectively removes pollution in the wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com