Formula and preparation method of impermeable waterproof concrete repairing agent

A technology of anti-seepage waterproofing and repairing agent, which is applied in the field of concrete waterproofing, which can solve the problems of aggravating the corrosion of steel bars and achieve the effects of increasing compactness, improving compactness, improving impermeability and waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a concrete anti-seepage and waterproof repairing agent, comprising the following steps:

[0027] A: Divide distilled water into 4 parts, dissolve sodium silicate, potassium metaaluminate, sodium carbonate and sodium dodecylsulfonate in one part of distilled water respectively to form sodium silicate solution, potassium metaaluminate solution, carbonic acid Sodium solution and sodium dodecylsulfonate solution;

[0028] B: Add the prepared potassium metaaluminate solution to the prepared sodium silicate solution;

[0029] C: Add the prepared sodium carbonate solution to the solution in the B step;

[0030] D: adding propylene glycol to the solution prepared in the C step;

[0031] E: Add isooctyl polyvinyl ether to the prepared sodium dodecylsulfonate solution;

[0032] F: Mix the solution prepared in step E with the solution prepared in step D, and stir evenly.

[0033] At the same time, sodium hydroxide can be added to the sodium silicate sol...

Embodiment 1

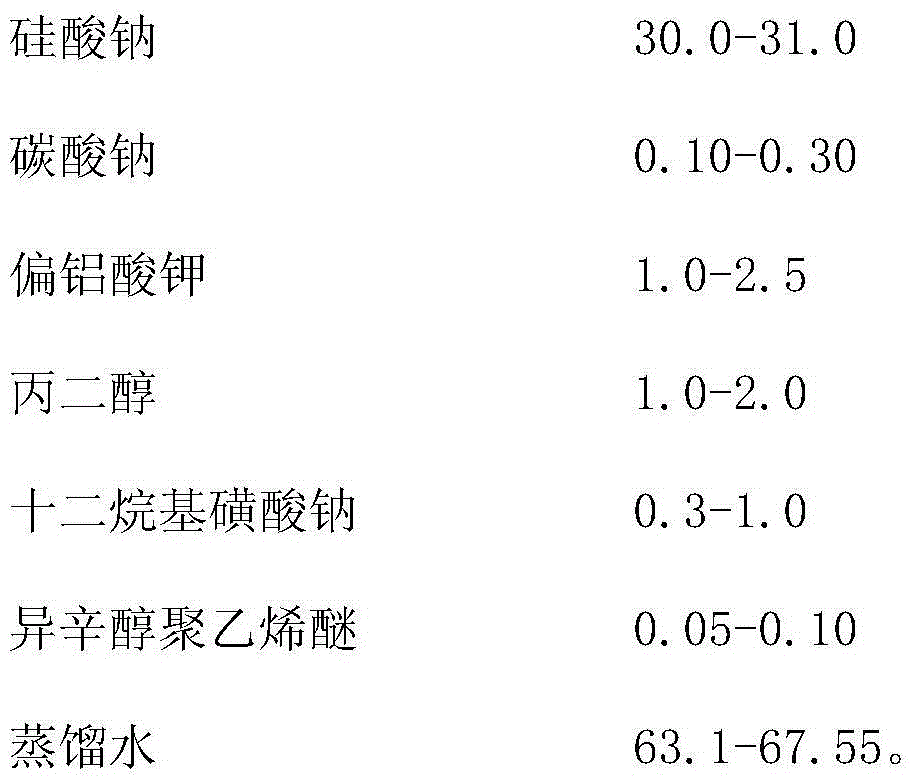

[0035] Embodiment one: a kind of concrete anti-seepage and waterproof repairing agent formula, each component by weight percentage, comprises:

[0036]

[0037] Taking the preparation of 200 grams of concrete anti-seepage and waterproof repair agent as an example, the preparation method may further comprise the steps:

[0038] A: Divide the distilled water into 4 parts, dissolve 61 grams of sodium silicate in 80 grams of distilled water, 4 grams of potassium metaaluminate in 20 grams of distilled water, 0.5 grams of sodium carbonate in 10 grams of distilled water, 1.4 grams of dodecylsulfonic acid Dissolve sodium in 20 grams of distilled water to form sodium silicate solution, potassium metaaluminate solution, sodium carbonate solution and sodium dodecylsulfonate solution respectively;

[0039] B: Add the prepared potassium metaaluminate solution to the prepared sodium silicate solution;

[0040] C: Add the prepared sodium carbonate solution to the solution in the B step; ...

Embodiment 2

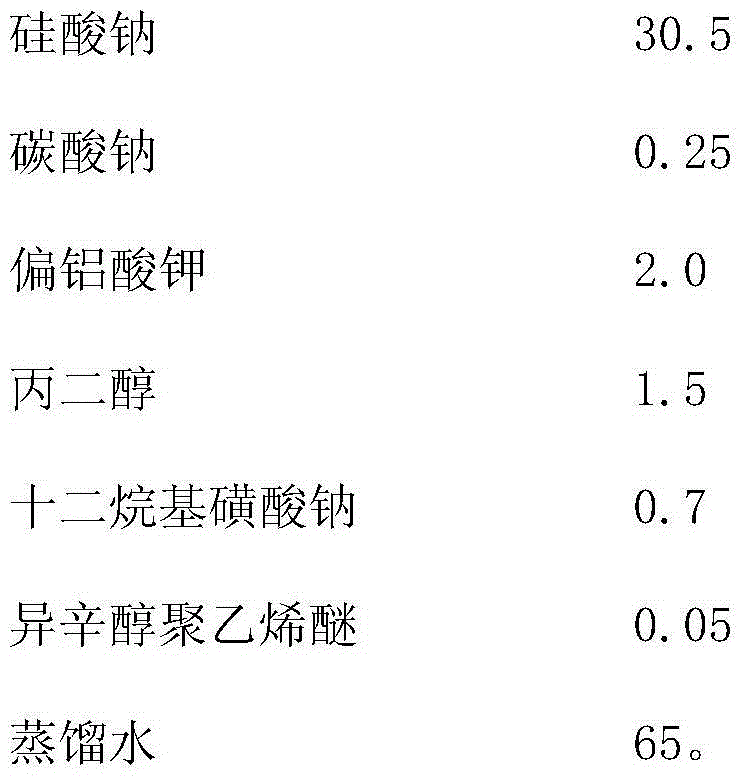

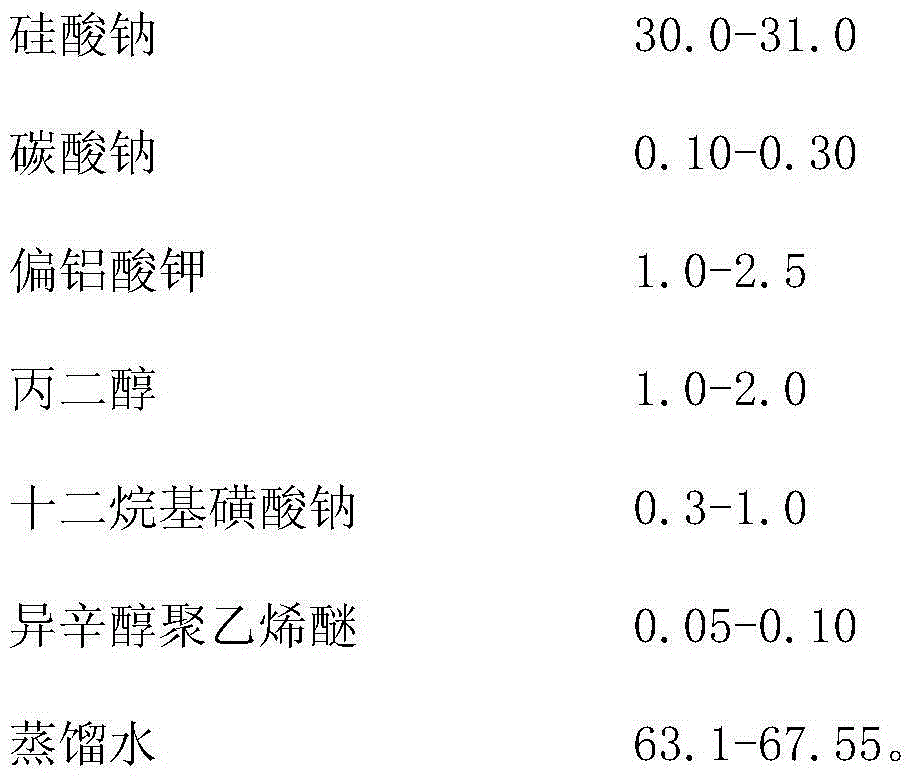

[0044] Embodiment two: a kind of concrete anti-seepage and waterproof repairing agent formula, each component by weight percentage, comprises:

[0045]

[0046]

[0047] Taking the preparation of 200 grams of concrete anti-seepage and waterproof repair agent as an example, the preparation method may further comprise the steps:

[0048] A: Divide the distilled water into 4 parts, dissolve 60 grams of sodium silicate in 80 grams of distilled water, 0.2 grams of sodium carbonate in 20 grams of distilled water, 2 grams of potassium metaaluminate in 15.1 grams of distilled water, 0.6 grams of dodecylsulfonic acid Dissolve sodium in 20 grams of distilled water to form sodium silicate solution, potassium metaaluminate solution, sodium carbonate solution and sodium dodecylsulfonate solution respectively;

[0049] B: Add the prepared potassium metaaluminate solution to the prepared sodium silicate solution;

[0050] C: Add the prepared sodium carbonate solution to the solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com