A hollow reinforced concrete precast wall module

A reinforced concrete and prefabricated wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing the difficulty of processing wall modules and building construction, difficult to guarantee, and low building efficiency, so as to ensure the building's competitiveness and overall The effect of improving sex and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

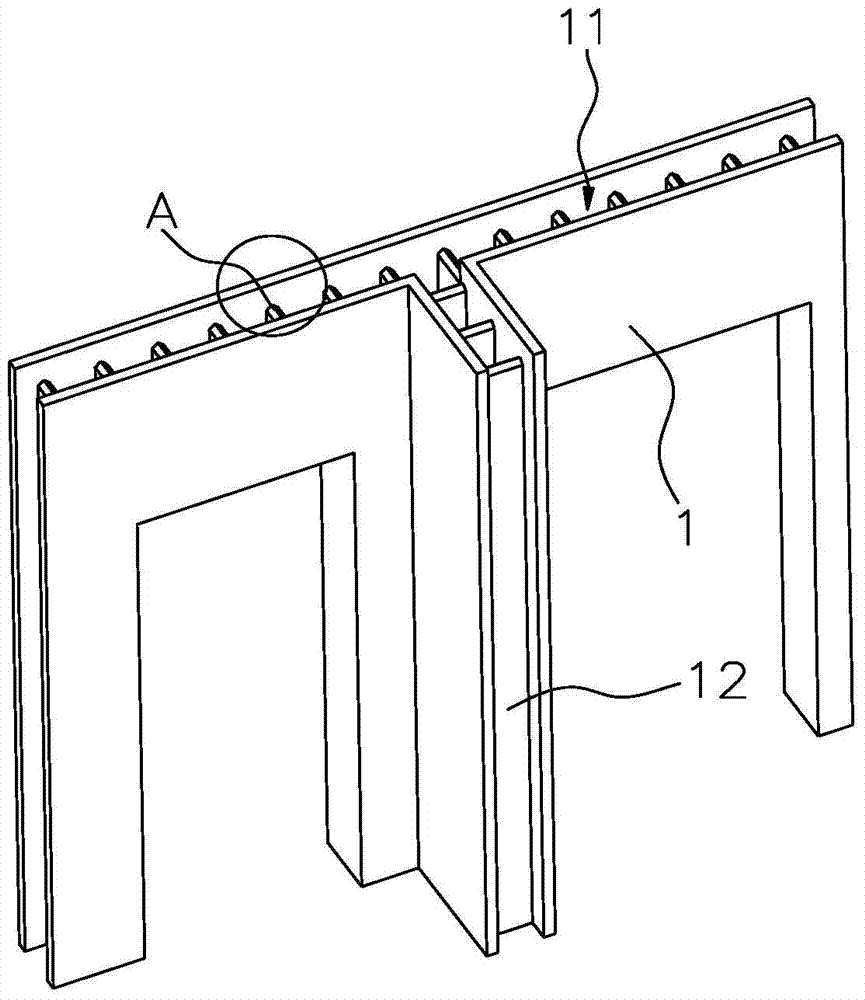

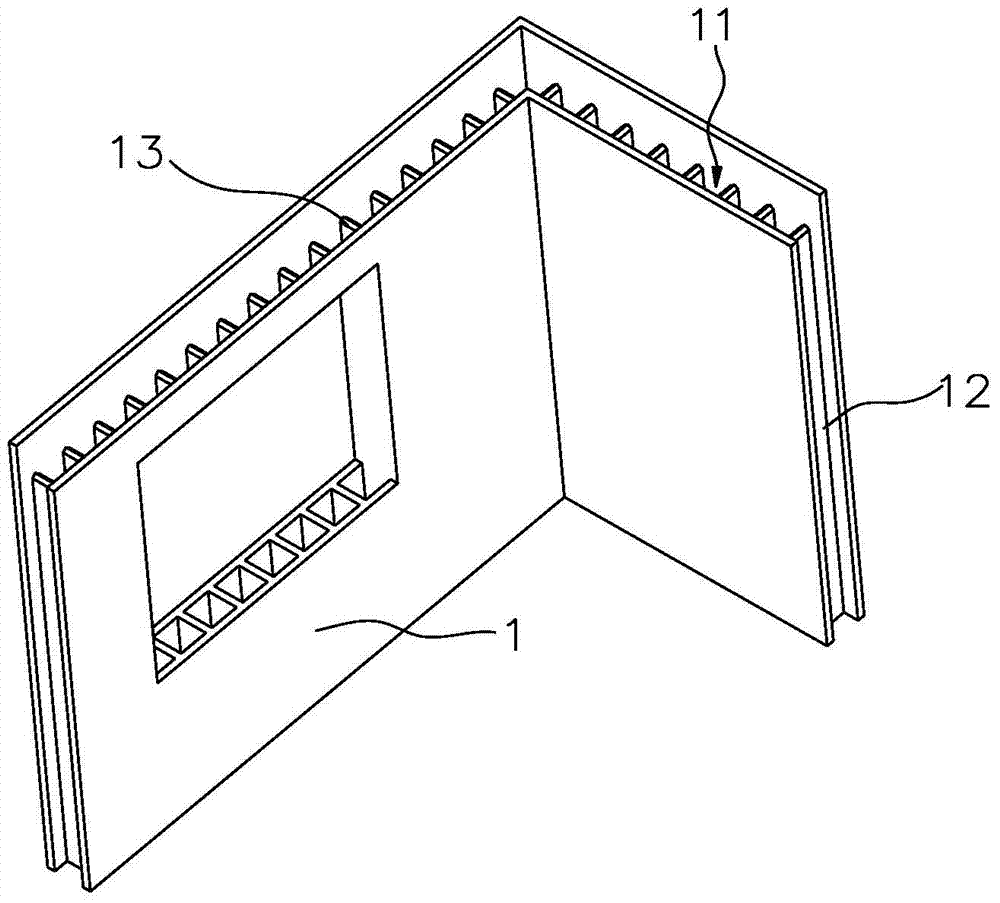

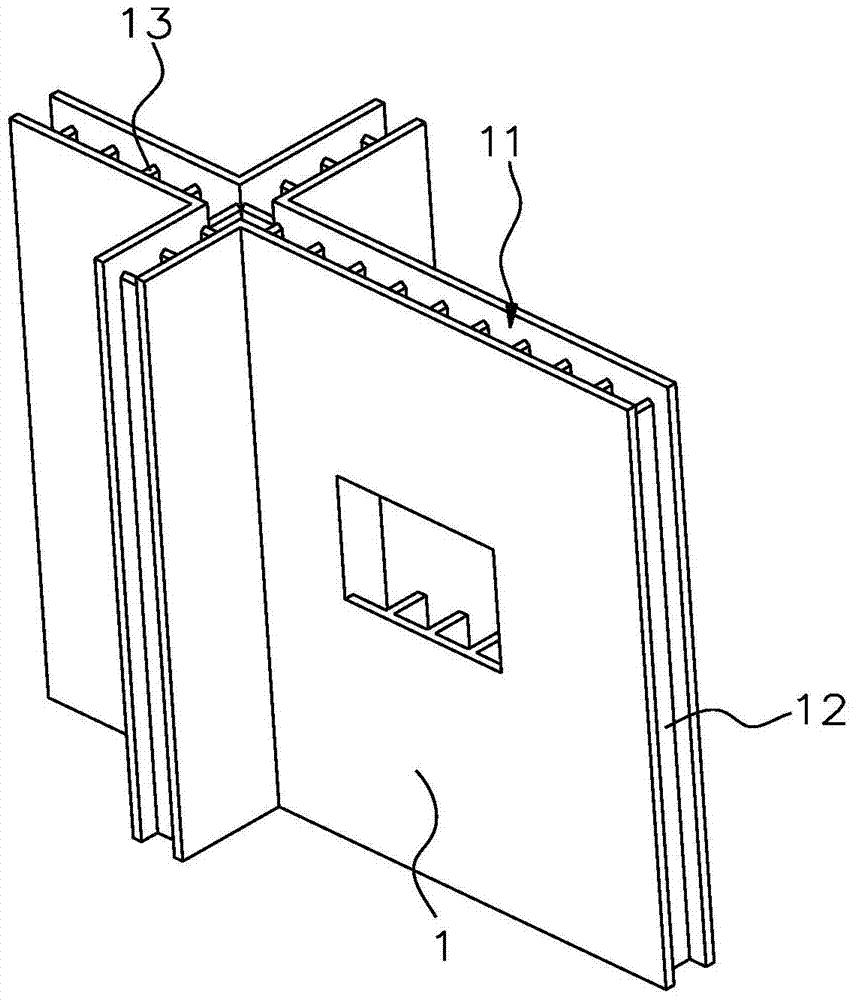

[0034] The hollow wall body module 1 of the present invention is made of prefabricated reinforced concrete. The module 1 is figure 1 T-shape shown, or figure 2 The L-shape shown; the T-shape and L-shape mainly refer to the top view contour shape after installation, that is, the top view contour shape shown in the figure. still can be image 3 The shown cross shape; or the simpler one-shaped module, the one-shaped module is the simplest, so it is not shown in the figure to save space; through the combination of the above-mentioned several basic shapes of modules 1, the building construction needs of different apartment types and structures can be met. This is similar to the prior art and can be further improved.

[0035] Such as figure 1 , 2 As shown in , 3, a plurality of through holes 11 vertically penetrating the module 1 are uniformly arranged on the module 1 of the present invention. The through hole 11 is different from the through hole in the prior art that is pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com