Shapable type white-light AC LED light source and manufacturing method thereof

A plastic and white light technology, applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of unfavorable LED lamp promotion, unfavorable lamp individual design, unfavorable LED development, etc., and achieves good shape plasticity, simple and low-cost lamp manufacture. The effect of light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

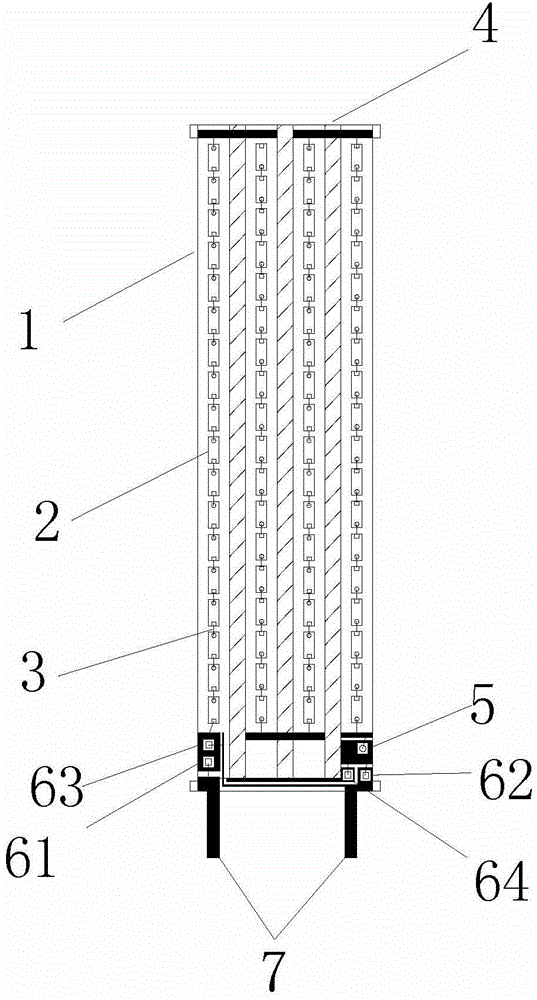

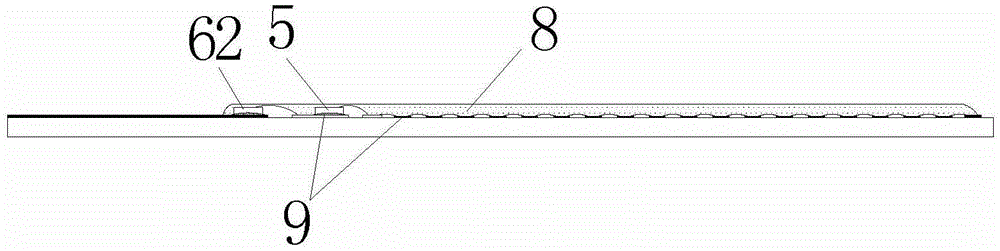

[0020] Such as figure 1 and figure 2 As shown, the plastic white AC LED light source includes more than two metal substrates 1, plastic flexible PCB 4, chip 2, gold wire 3, reverse polarity constant current diode wafer 5, rectifier circuit, pin 7, fluorescent glue 8 and silver glue 9.

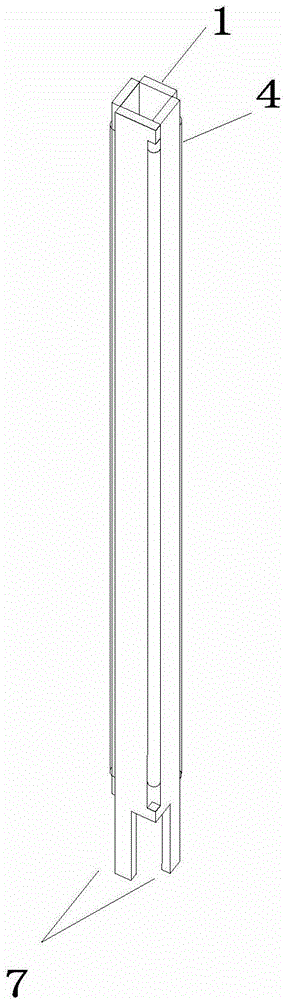

[0021] In this embodiment, the metal substrate is a copper substrate with a thermal conductivity of 390W / m.K. The copper substrate has a length of 44mm, a width of 0.8mm, and a width of 9mm. In this embodiment, there are four copper substrates. Adjacent copper substrates are connected through a plastic flexible PCB 4, so that, as image 3 As shown, the foldable copper substrate, users can adjust the light angle according to their own needs, and there can be gaps between adjacent copper substrates, or no gaps.

[0022] A 60-mil silver layer is plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com