Determination method of calcium oxide content in open-hearth slag, converter slag and electro-furnace slag

A measurement method, the technology of converter slag, which is applied in the direction of chemical analysis by titration method, can solve the problems of time-consuming, etc., and achieve the effects of low cost, shortened operation process and stable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

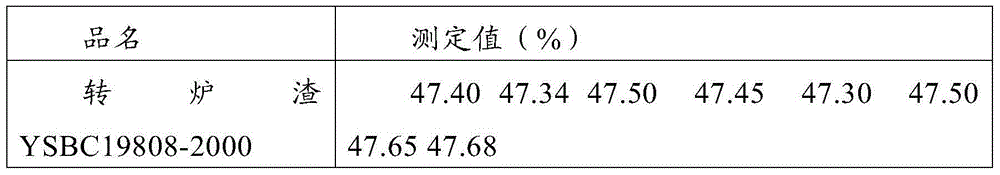

Image

Examples

Embodiment Construction

[0027] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0028] 1. Method summary: Dissolve the sample in a polytetrafluoroethylene plastic beaker with hydrochloric acid (65%), nitric acid (67%)-hydrofluoric acid (40%), add sulfuric acid to smoke (1 -2 minutes, the sample is in the form of wet salt, if the sulfuric acid smokes for too long, barium sulfate and calcium sulfate will generate barium persulfate and calcium persulfate, which cannot be dissolved by adding hydrochloric acid in the later stage, which will affect the measurement results. In addition, the beaker There is black residue in the middle sample, and after the residue treatment, the calcium in the residue is zero. Therefore, it can be said that after a series of acid treatments in the early stage, the calcium in the sample has been completely dissolved, so the calcium can be directly measured in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com