Anti-mouse telephone lead-in line

A telephone lead-in, rodent-proof technology, applied in circuits, electrical components, insulated cables, etc., can solve the problems of limited electrical performance improvement, increased construction difficulty, limited tensile strength, etc. Intensity, attenuation can be reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

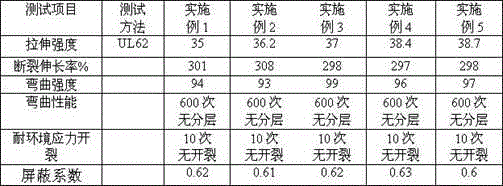

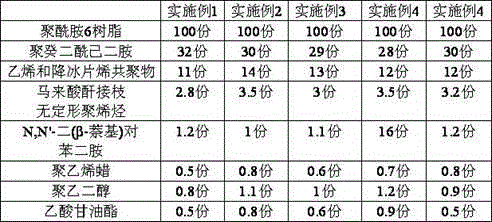

Embodiment 1~5

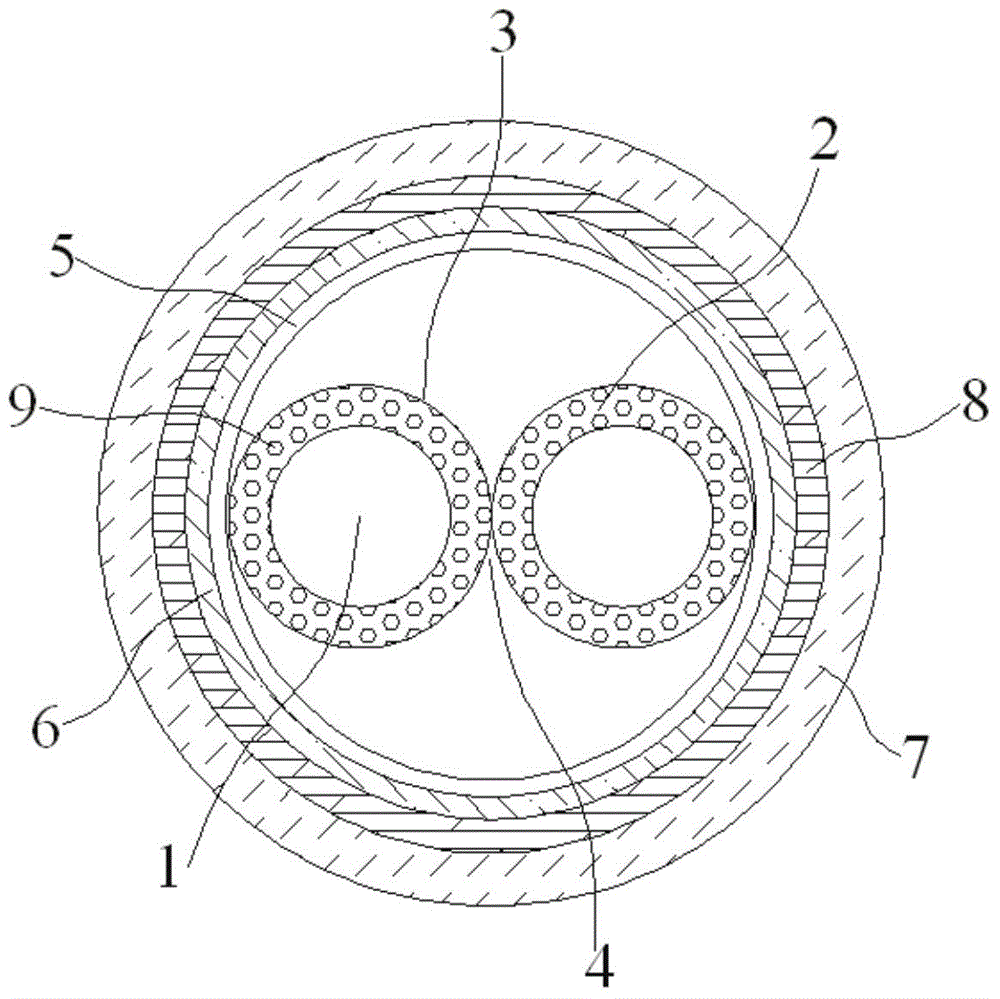

[0024] Embodiments 1 to 5: A rodent-proof type telephone lead-in wire, comprising two round copper conductors 1, the outer surface of the round copper conductors 1 is covered with a polyethylene layer 2 to form a wire 3, and the polyethylene layer 2 contains Several air holes 9, the volume ratio of the several air holes 9 accounting for the polyethylene layer 2 is 40-60%, the air holes 10 are filled with nitrogen, the two wires 3 are twisted to form a twisted wire pair 4, an aluminum foil 5 Wrapped on the outer surface of the twisted wire pair 4, a polyvinyl chloride layer 6 is wrapped on the outer surface of the aluminum foil 5, and a polyethylene sheath layer 7 is wrapped on the outer surface of the polyvinyl chloride layer 6, the An intermediate tensile layer 8 is arranged between the polyvinyl chloride layer 6 and the polyethylene sheath layer 7;

[0025] The thickness ratio of the polyvinyl chloride layer 6 to the middle tensile layer 8 is 10:5 or 10:5.5, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com