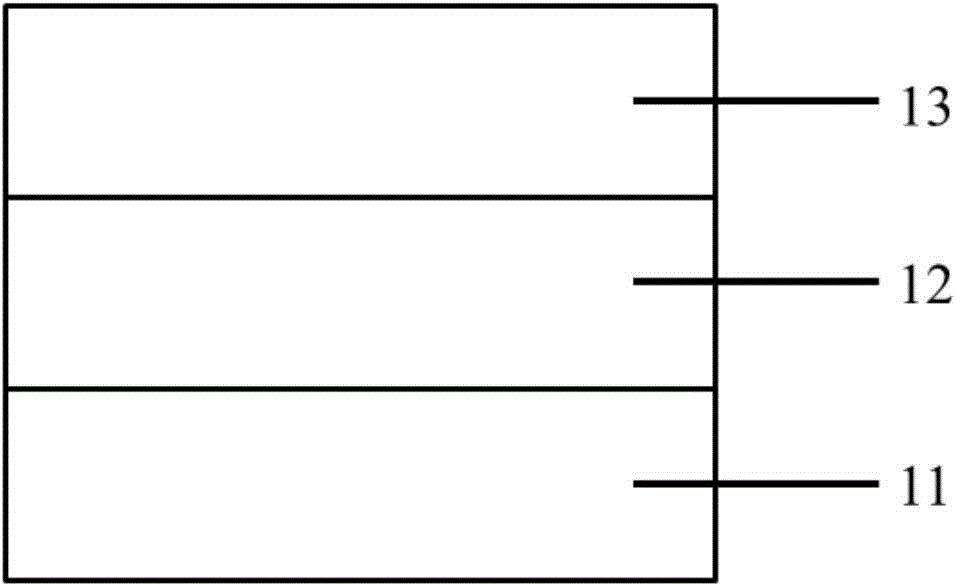

GaAs thin film growing on Si substrate and method for preparing same

A substrate and thin film technology, applied in the field of GaAs thin films and their preparation, can solve problems affecting the surface flatness of GaAs semiconductor devices, etc., and achieve a simplified buffer layer structure and an epitaxial growth process, the technical means are simple and feasible, and the epitaxial growth process is simplified Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

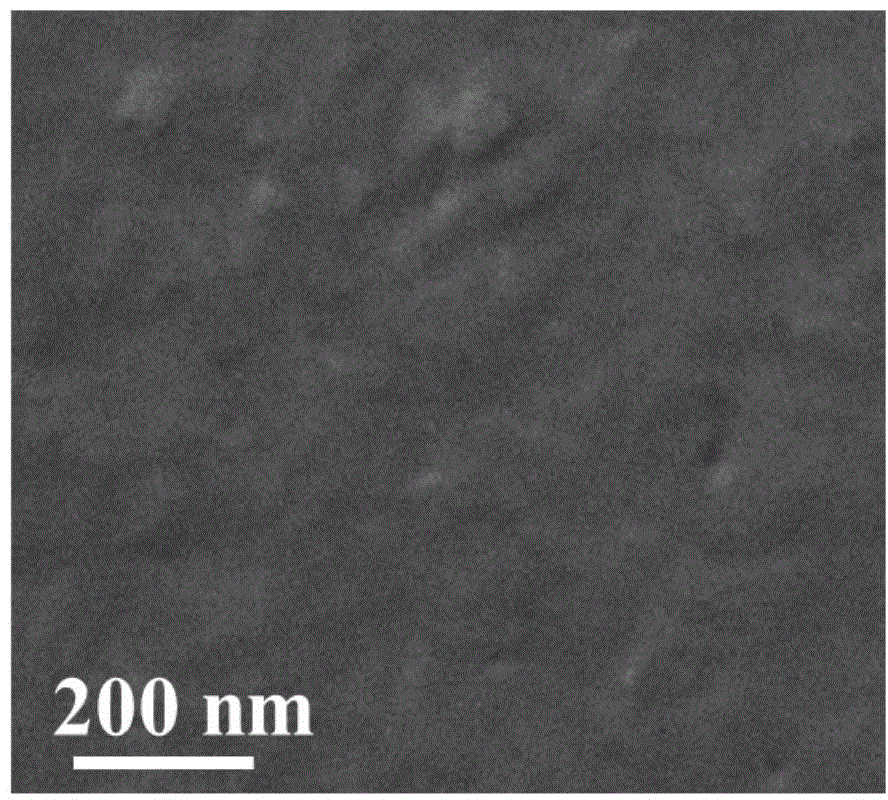

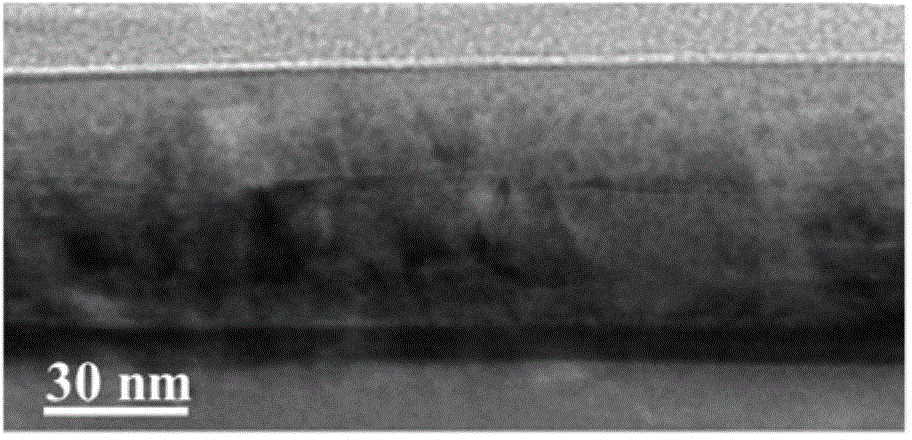

Embodiment 1

[0036] The preparation method of the GaAs thin film grown on the Si substrate of the present embodiment comprises the following steps:

[0037] (1) Si substrate cleaning: After washing with acetone and deionized water, organic matter on the surface of the substrate is removed; the Si substrate is placed in HF:H 2 Ultrasound in O=1:10 solution for 1 minute, then rinse with deionized water to remove surface oxides and organic matter; dry the cleaned Si substrate with high-purity nitrogen;

[0038] (2) Si substrate pretreatment: After the Si substrate is cleaned, send it to the molecular beam epitaxy sampling chamber for pre-degassing for 15 minutes; then send it to the transfer chamber for degassing at 300°C for 2 hours, and send it to the growth chamber after degassing;

[0039] (3) Deoxidation film on Si substrate: After Si substrate enters the growth chamber, raise the substrate temperature to 950-1050°C, bake at high temperature for 15-30 minutes, and remove the oxide film l...

Embodiment 2

[0047] The preparation method of the GaAs thin film grown on the Si substrate of the present embodiment comprises the following steps:

[0048] (1) Si substrate cleaning: After washing with acetone and deionized water, organic matter on the surface of the substrate is removed; the Si substrate is placed in HF:H 2 Ultrasonic in O=1:10 solution for 10 minutes, then rinsed with deionized water to remove surface oxides and organic matter; the cleaned Si substrate was dried with high-purity nitrogen;

[0049] (2) Si substrate pretreatment: After the Si substrate is cleaned, send it to the molecular beam epitaxy sampling chamber for pre-degassing for 30 minutes; then send it to the transfer chamber for degassing at 400°C for 0.5 hours, and then send it to the growth chamber after degassing;

[0050] (3) Si substrate deoxidation film: after the Si substrate enters the growth chamber, the temperature of the substrate is raised to 1050 ° C, and the high temperature is baked for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com