Preparation method of butyl rubber

A technology of butyl rubber and mixture solution, which is applied in the field of polymerization reaction, can solve the problems of incomparable cost and initiation efficiency, and achieve the effects of avoiding equipment operation and production instability, easy content control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

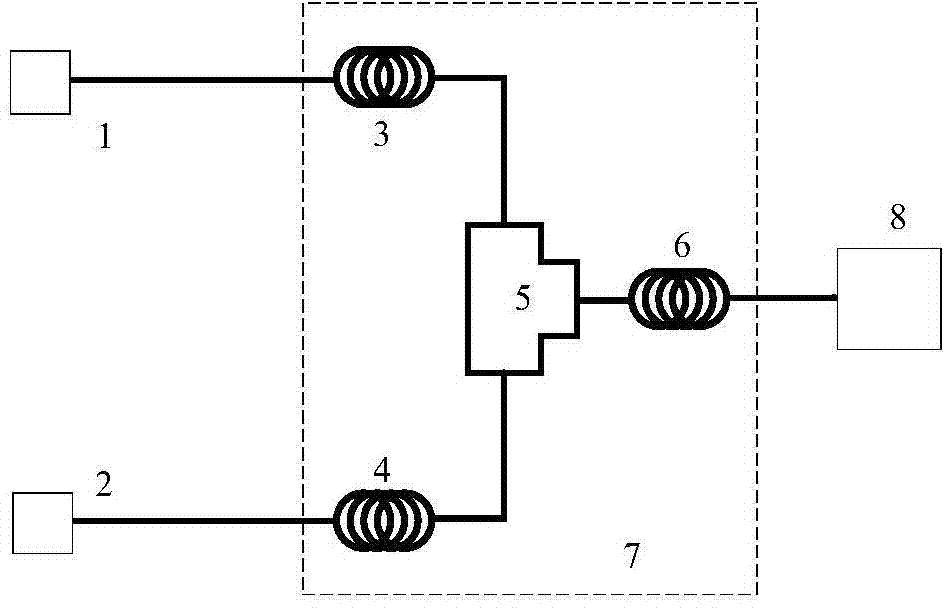

Image

Examples

Embodiment 1

[0040] This embodiment uses a T-shaped three-way mixer with a diameter of 0.5 mm. In the prepared monomer mixture solution, the isomeric monoolefin is selected from isobutene, the conjugated diene is selected from isoprene, the molar ratio of isobutene and isoprene is 40:1, the diluent is anhydrous dichloromethane, and the diluent Accounting for 90%wt of the monomer mixture solution. In the prepared initiator mixture solution, Lewis acid is selected from AlCl 3 , AlCl 3 The molar ratio with water is 1.6:1, the diluent is anhydrous dichloromethane, and the content of water in the initiator mixture solution is 16ppm. The flow rate of the monomer mixture solution is 8 mL / min, the flow rate of the initiator mixed solution is 8 mL / min, the reaction temperature is -80° C., and the reaction residence time is 1 s. The number average molecular weight Mn of the butyl rubber product is 1.5×10 5 , the molecular weight distribution index was 2.50, and the yield was 62%.

Embodiment 2

[0041] Example 2: The molar ratio of isobutylene to isoprene is 200:1, other conditions are the same as in Example 1, and the number average molecular weight Mn of the butyl rubber product obtained is 5.0×10 5 , the molecular weight distribution index was 1.80, and the yield was 100%.

Embodiment 3

[0042] Embodiment 3: the reaction temperature is controlled as -40 DEG C, and other conditions are the same as embodiment 1, and the number average molecular weight Mn that obtains butyl rubber product is 1.2 * 10 5 , the molecular weight distribution index was 2.04, and the yield was 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com