Water-based ink for negative ion decorative paper and preparation method therefor

A technology of water-based ink and negative ions, which can be used in ink, household utensils, applications, etc., and can solve the problem of brittle film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

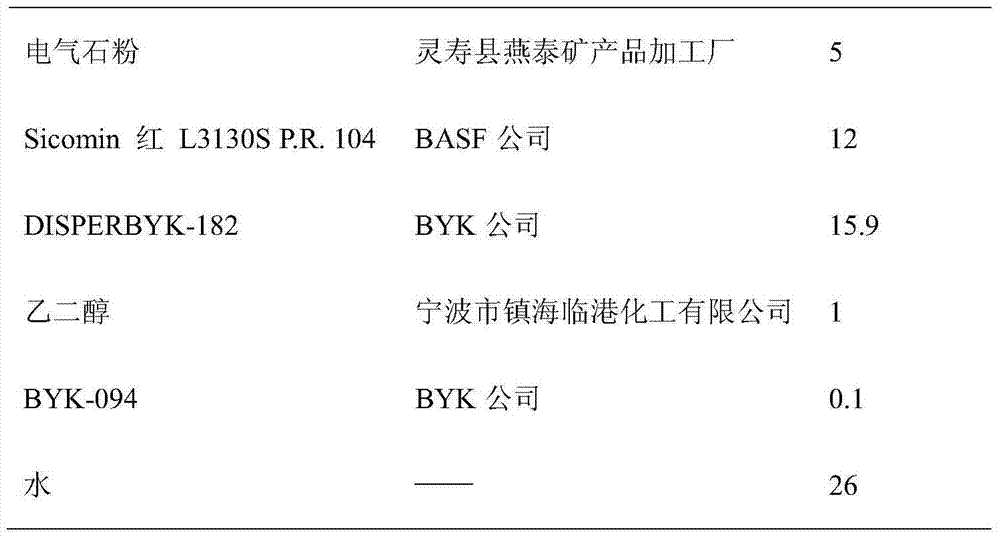

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Grinding of negative ion red paste

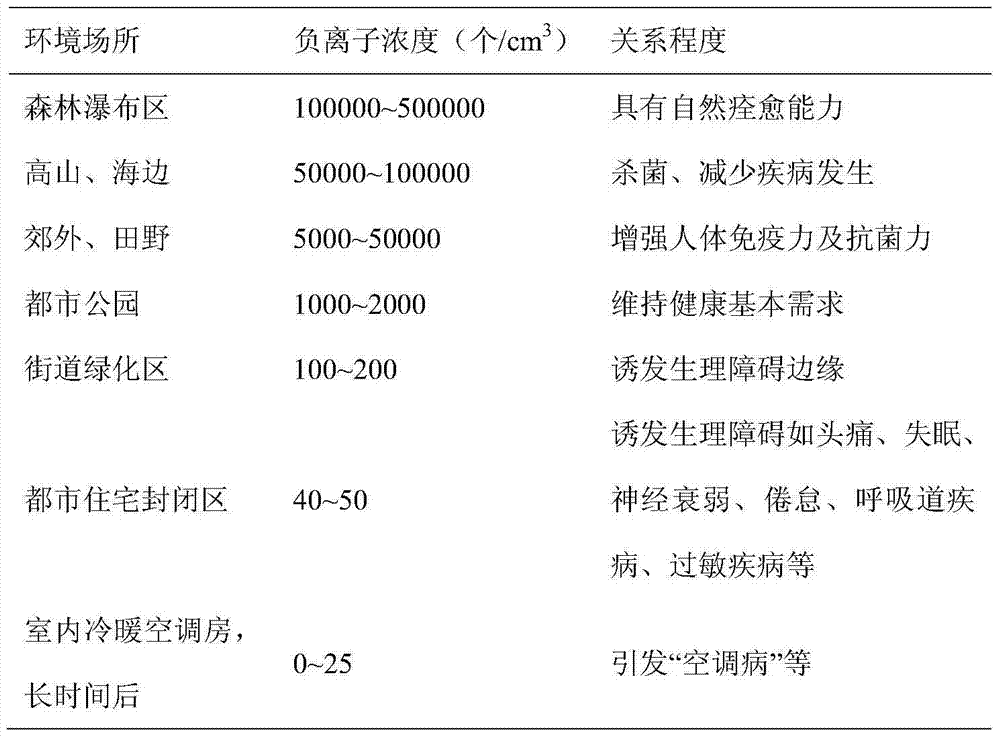

[0070] Table 1 Negative ion red pulp formula table

[0071]

[0072]

[0073] According to the formulation amount in Table 1, water, tourmaline powder negative ion additive, Sicomin red L3130S P.R.104 red pigment, DISPERBYK-182 wetting and dispersing agent, ethylene glycol, BYK-094 defoamer with half the formulation amount and a diameter of 2mm Put the glass beads into the fast dispersing machine (KS-370 coating fast dispersing machine, Shanghai Modern Environmental Engineering Technology Co., Ltd.), grind and disperse for 3 hours, and then add the remaining half of the formula amount of BYK-094 defoamer to obtain negative ion red paste ;

[0074] (2) Preparation of modified casein solution

[0075] Table 2 Modified casein liquid formula table

[0076]

[0077] According to the formula quantity in Table 2, 182kg of water is added in the flask, and the stirring speed of 100rpm is maintained, 40kg of casein protein is a...

Embodiment 2

[0083] (1) Grinding of negative ion yellow paste

[0084] Table 4 Negative ion yellow paste formula table

[0085]

[0086] According to the formulation amount in Table 4, mix water, tourmaline powder negative ion additive, Paliotol yellow L1820P.Y.139 yellow pigment, DISPERBYK-182 wetting and dispersing agent, ethylene glycol, BYK-094 defoamer and diameter Put 2mm glass beads into a fast dispersing machine (KS-370 coating fast dispersing machine, Shanghai Modern Environmental Engineering Technology Co., Ltd.), grind and disperse for 2 hours, then add the remaining half of the formula amount of BYK-094 defoamer to get negative ions yellow paste;

[0087] (2) Preparation of modified casein solution

[0088] Table 5 Modified casein liquid formula table

[0089]

[0090] According to the formula amount in Table 5, 190kg of water is added in the flask, and the stirring speed of 140rpm is maintained, 48kg of casein protein is added, the temperature of the system is raised ...

Embodiment 3

[0097] (1) Grinding of negative ion white pulp

[0098] Table 7 Negative ion white pulp formula table

[0099]

[0100] According to the formulation amount in Table 7, water, tourmaline powder negative ion additive, R-706 titanium dioxide, DISPERBYK-182 wetting and dispersing agent, ethylene glycol, BYK-094 defoamer with half the formulation amount and glass with a diameter of 2mm Put the beads into the fast dispersing machine (KS-370 coating fast dispersing machine, Shanghai Modern Environmental Engineering Technology Co., Ltd.), grind and disperse for 2 hours, then add the remaining half of the formula amount of BYK-094 defoamer to obtain negative ion white paste;

[0101] (2) Preparation of modified casein solution

[0102] Table 8 Modified casein solution formula table

[0103]

[0104]

[0105] According to the formula amount in Table 8, 192kg of water is added in the flask, and the stirring speed of 100rpm is maintained, 40kg of casein protein is added, the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com