P type gallium-doped crystalline silicon and preparation method thereof

A crystalline silicon, N-type technology, applied in the field of solar photovoltaic material preparation, can solve the problems of serious silicon wafer compensation, inconvenient promotion, and inability to carry out production and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

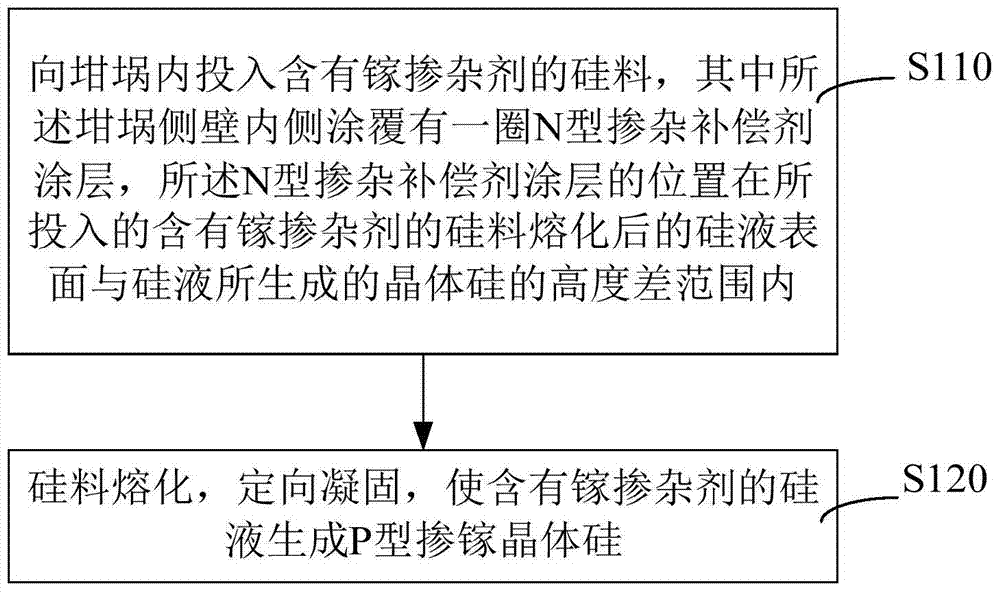

[0023] Please refer to figure 1 , discloses a preparation method of P-type gallium-doped crystalline silicon, comprising the following steps:

[0024] S110. Put silicon material containing gallium dopant into the crucible, wherein the inner side of the side wall of the crucible is coated with a circle of N-type doped compensator coating, and the position of the N-type doped compensator coating is at the input The height difference between the surface of the silicon liquid after melting the silicon material containing the N-type dopant and the crystalline silicon generated by the silicon liquid is within the range.

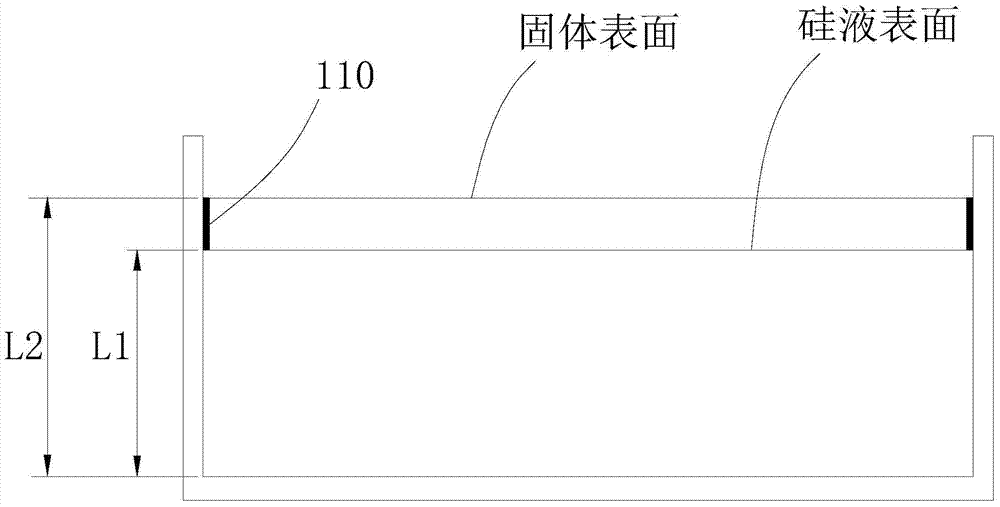

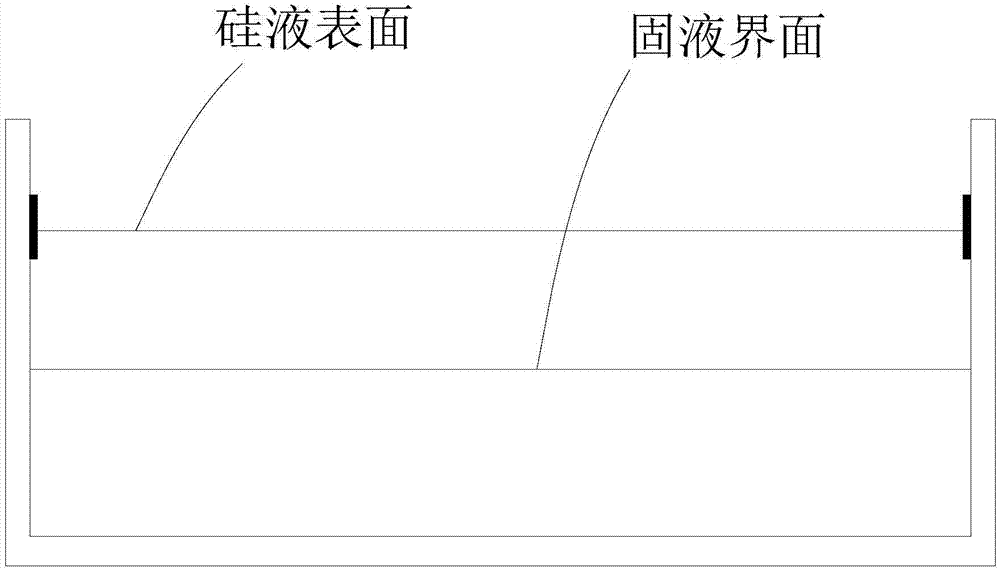

[0025] Please refer to figure 2 The height of the silicon liquid surface from the bottom of the crucible after the silicon material containing gallium dopant is melted in the crucible is L1, the height of the crystalline silicon generated by the silicon liquid is L2, and the position of the N-type doped compensator coating 110 is at Between L1 and L2, the height...

Embodiment 1

[0034] 1. Select an appropriate amount of P powder or silicon-phosphorus alloy as the N-type compensator, dilute it with silicon powder and quartz powder and add an appropriate amount of binder as the raw material for coating.

[0035] 2. Spray silicon nitride coating normally on the inner wall of the crucible.

[0036] 3. Then determine the coating position by calculation, and coat the prepared raw materials within the calculated position range by spraying or brushing to form a layer of coating, in which the ingot with a charging capacity of 480kg and the inner diameter of the crucible is 840mm, It is calculated that the height of the silicon liquid surface after melting is 268mm, and the crystal height after the crystal growth is 292mm, so it can be determined that the coating position is between 268-292mm from the bottom of the crucible.

[0037] 4. Put 480kg of a mixture of polysilicon material and pure gallium into the crucible, wherein the doping concentration of gallium...

Embodiment 2

[0043]1. Select an appropriate amount of antimony powder or silicon-antimony alloy, dilute it with silicon powder and quartz powder and add an appropriate amount of binder as the raw material for coating.

[0044] 2. The position of the coating is determined by calculation, and the prepared coating raw materials are fixed in the determined position range by spraying or brushing to form a layer of coating with compensation ability. The ingot with a charging capacity of 800kg, the crucible The inner diameter is 1000mm, the height of the silicon liquid surface after melting is 314mm, and the crystal height after the crystal growth is 343mm, so the coating position is determined to be between 314-343mm from the bottom of the crucible.

[0045] 3. Then continue to spray silicon nitride coating on the inner wall of the crucible.

[0046] 4. Put 800kg of polysilicon and pure gallium mixture into the crucible.

[0047] 5. Directional solidification, which melts the primary polysilico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com