Integrated wall system

A technology for integrating walls and wall frames, applied to walls, building components, buildings, etc., to achieve the effects of good overall stability, strong clamping force, and low heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

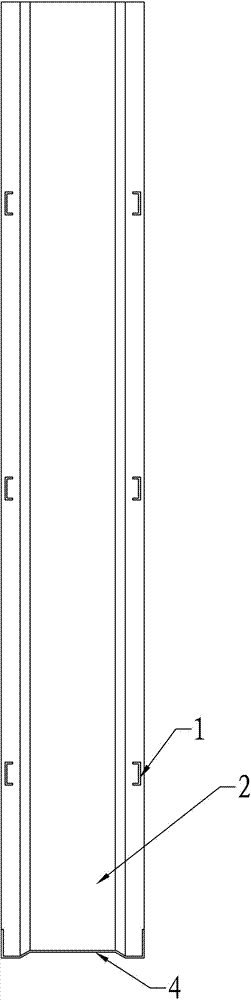

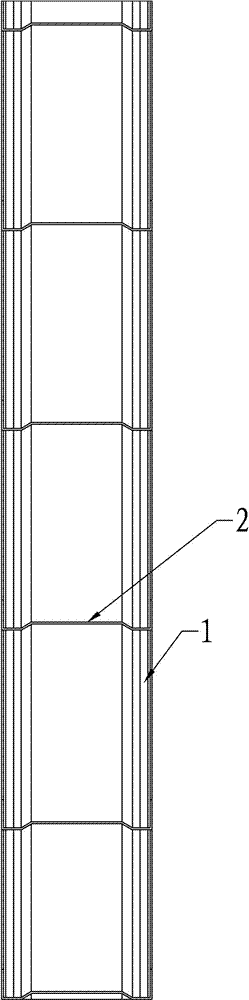

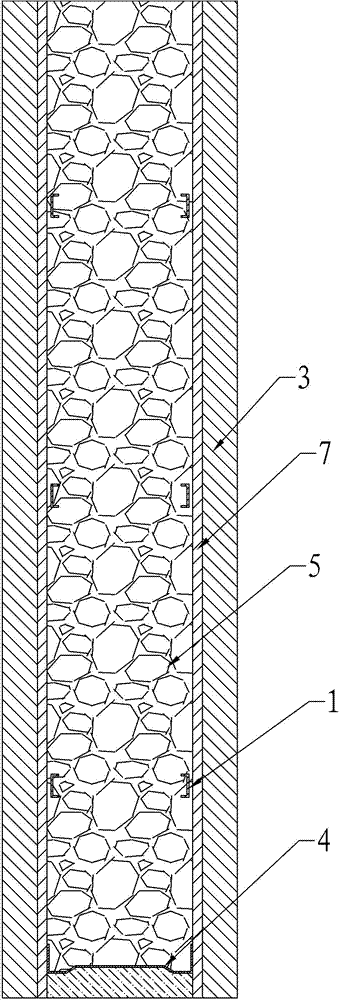

[0025] refer to Figure 1 to Figure 3 , an integrated wall system, which includes a vertical and horizontal light steel keel clamped vertically and horizontally to form an interspersed and clamped light steel structure wall frame skeleton, and is also provided with an installation keel 4 connected and fixed to the main body of the building. The installation keel 4 and One or both of the transverse keel 1 and the longitudinal keel 2 are fixedly connected, and the two sides of the wall frame frame are provided with bonding and anchoring techniques to fix the overlay fiberboard 3 and the wall frame frame to form a stable cavity wall. To strengthen the safety and stability performance of this embodiment, an anti-crack reinforcing fiber net 7 is added, cement-based fiber adhesive is glued on the anti-crack reinforcing fiber net 7, and then filled in the cavity of the wall and poured into the cavity of the wall. The injected cement-based lightweight slurry 5 is mutually bonded and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com