Flexible erasable SERS (surface-enhanced Raman scattering) active substrate and preparation method thereof

A substrate and flexible support technology, applied in the field of SERS substrates, can solve the problems of low detection ability, inability to complex explosive molecules, and inability to detect explosives, etc., and achieve the effects of short sampling time and simple sampling steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] More specifically, the method for preparing a flexible and wipeable surface-enhanced Raman substrate of the present invention includes the following steps:

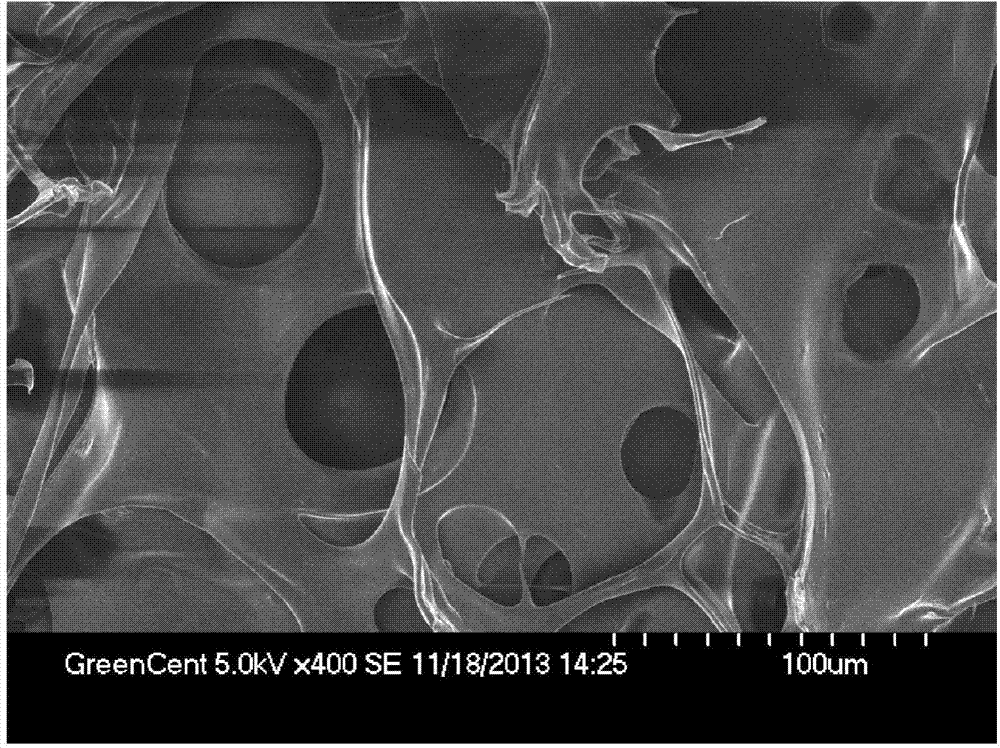

[0034](1) At least one of polyacrylamide, polyvinyl alcohol and chitosan is selected as the basic raw material, and the raw material is dissolved to obtain an aqueous solution. If chitosan is used, an aqueous acetic acid solution can be used for dissolution. During the dissolution process, proper heating can be used to promote the dissolution rate and dissolution rate of the raw materials. The completely dissolved solution is frozen at a temperature below -20°C for 4 to 24 hours to completely freeze the water in it into ice. The completely frozen raw materials are placed in a freeze dryer for vacuum freeze-drying treatment for 4-96 hours, preferably freeze-dried for 24-72 hours, to prepare a flexible support material (flexible support layer) with a porous structure.

[0035] (102) Put the above-mentioned flexible ...

Embodiment 1

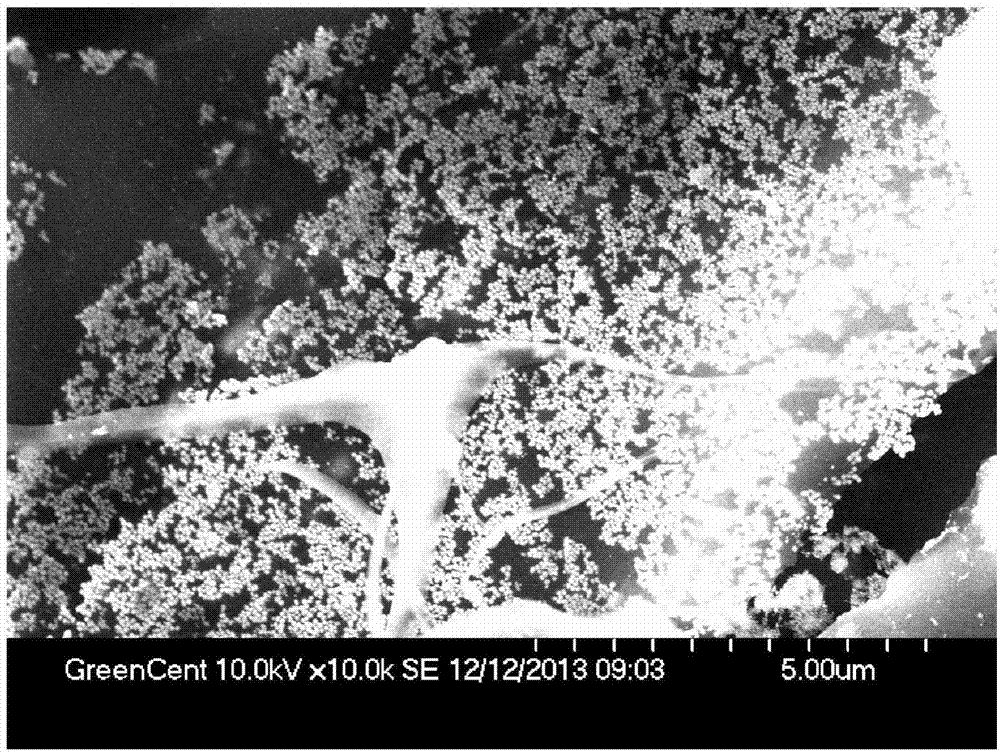

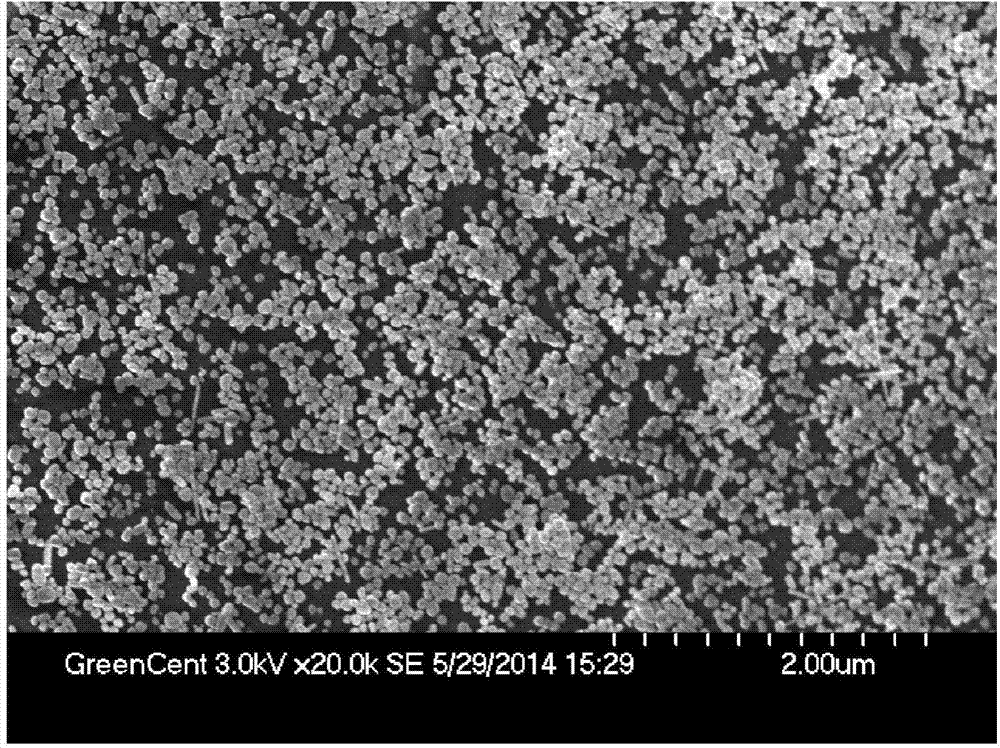

[0044] Preparation of flexible nano-gold surface-enhanced Raman substrates:

[0045] 1) Preparation of flexible support layer with porous structure

[0046] Dissolve polyvinyl alcohol powder in an aqueous solution, heat and stir in a water bath until completely dissolved, and obtain a polyvinyl alcohol solution with a mass fraction of 8%. Weigh an appropriate amount of polyvinyl alcohol solution into a plastic disc, slowly add 4% borax aqueous solution dropwise and keep stirring, and place the polyvinyl alcohol solution in a -20°C refrigerator to freeze after it forms a gel state 4 hours. After the completely frozen polyvinyl alcohol was placed in a freeze dryer for 24 hours, a flexible support material with a porous structure was prepared. Put the flexible support layer with porous structure into deionized water for 30 minutes and ultrasonically clean it until the pH of the aqueous solution is ≈7, take out the flexible support layer with porous structure, and set aside. Th...

Embodiment 2

[0055] Preparation of flexible silver nanosphere surface-enhanced Raman substrate:

[0056] 1) Preparation of flexible support layer with porous structure

[0057] The chitosan powder was dissolved in an aqueous solution, placed in a water bath, heated and stirred until completely dissolved, and a chitosan solution with a mass fraction of 3% was prepared. Weigh an appropriate amount of chitosan solution and put it into a plastic disc, then place it in a refrigerator at -20°C for 12 hours. The fully frozen chitosan was put into a freeze dryer for 48 hours, and then a flexible support material with a porous structure was prepared. Put the flexible support layer with porous structure into deionized water for 10 minutes and ultrasonically clean it until the pH of the aqueous solution is ≈7, take out the flexible support layer with porous structure, and set aside.

[0058] 2) Preparation of silver nanosphere solution

[0059] Weigh 0.2 g of silver nitrate solid and dissolve it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com