Kilowatt-level optical fiber cladding power stripper employing micro-channel water cooling

A fiber cladding and microchannel technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as inability to dissipate heat in a timely and effective manner, sealing gasket aging, heat flux increase, etc., and achieve improved optical power stripping characteristics, improved heat dissipation uniformity, and improved temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

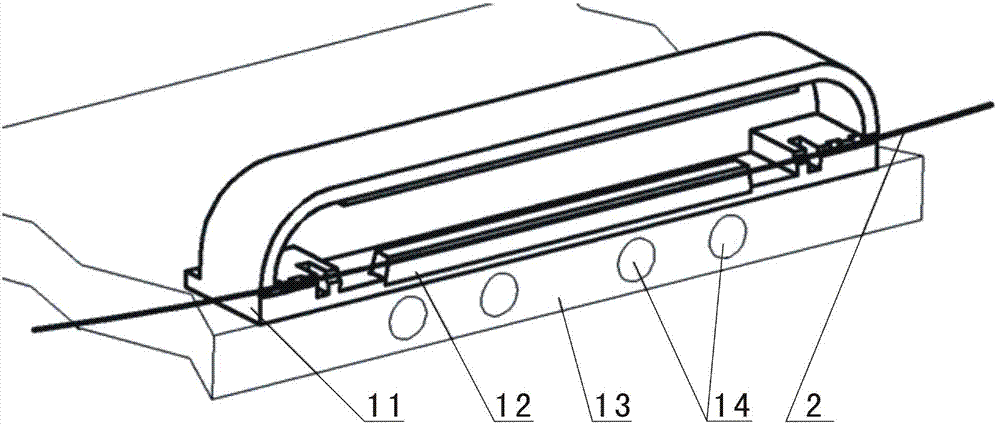

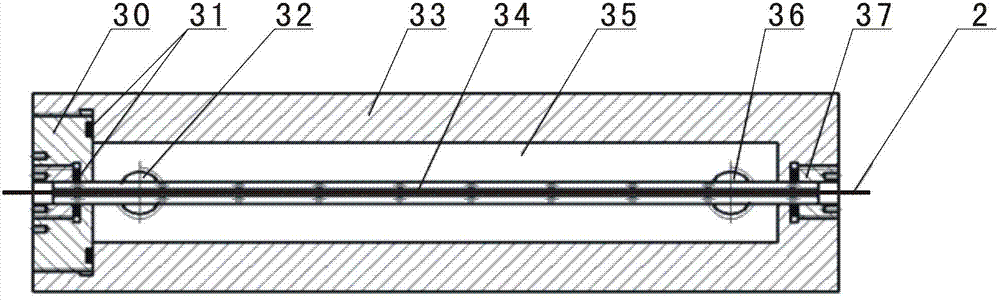

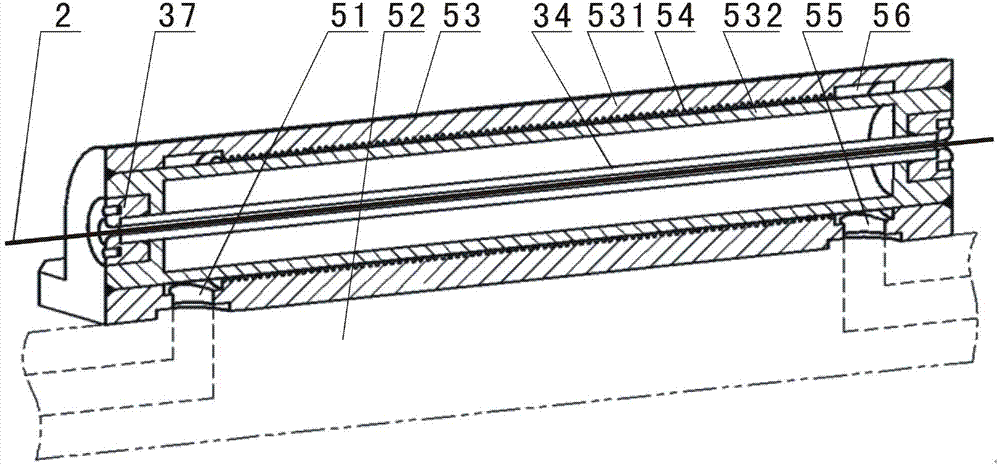

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] Such as Figure 3-Figure 8As shown, the kilowatt-level optical fiber cladding power stripper using microchannel water cooling in the present invention includes a heat sink 53, and the heat sink 53 includes a shell 531 made of high thermal conductivity 6061 aluminum alloy and a lining placed in the shell 531 532, the two ends of the housing 531 and the two ends of the inner liner 532 are connected by welding, the two ends of the inner liner 531 are respectively connected to the two ends of the glass tube 34 through the sealing head 37, the optical fiber 2 passes through the glass tube 34, The housing 531 is mounted on the base 52 and integrally formed with the base 52. The housing 531 is provided with a cooling water inlet 51 and a cooling water outlet 55 near both ends. Groove 54, the inner wall of housing 531 two ends is respectively provided with annular groove 56...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com