Pleurotus nebrodensis fungus chaff fermented feed and processing technology thereof

A technology for fermenting feed and Bailing mushroom, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of complex production technology and process flow, incomplete degradation of crude fiber, easy to be contaminated by mold, etc., and achieve high feed consumption. Value, improved sensory quality, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

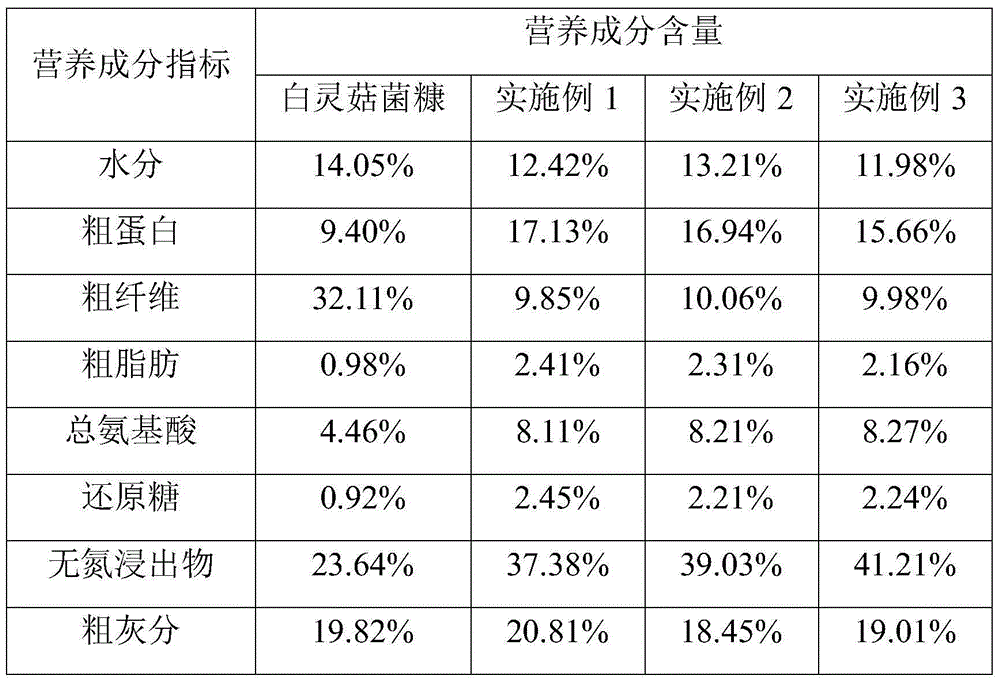

Embodiment 1

[0047] The fermented feed of Bailing mushroom chaff in this embodiment, the fermentation raw material is composed of Bailing mushroom chaff powder and corn starch, the weight ratio of Bailing mushroom chaff powder to jade starch is 18:1, and the inoculation of fermentation raw materials accounts for the weight of fermentation raw materials 7% of the bacterial liquid is then subjected to anaerobic fermentation treatment. The bacterial liquid is a mixed bacterial liquid of Candida liquid and Lactobacillus acidophilus liquid, the weight ratio of Candida liquid and Lactobacillus acidophilus liquid in the mixed liquid is 6:1, and the active bacteria in the Candida liquid The content is greater than 4.2 billion per gram, and the active bacteria content in the Lactobacillus acidophilus liquid is greater than 4 billion per gram. The specific content of each raw material in the present embodiment is: the quality of Bailing mushroom fungus chaff powder is 180kg, the quality of cornstarc...

Embodiment 2

[0058] The fermented feed of Bailing mushroom chaff in this embodiment, the fermentation raw material is composed of Bailing mushroom chaff powder and potato starch, the weight ratio of Bailing mushroom chaff powder to jade starch is 19:1, and the inoculation of fermentation raw materials accounts for the weight of fermentation raw materials 6% of the bacterial liquid is then subjected to anaerobic fermentation treatment. The bacterial liquid is a mixed bacterial liquid of Candida liquid and Lactobacillus acidophilus liquid, the weight ratio of Candida liquid and Lactobacillus acidophilus liquid in the mixed liquid is 7:1, and the active bacteria in the Candida liquid The content is greater than 4.2 billion per gram, and the active bacteria content in the Lactobacillus acidophilus liquid is greater than 4 billion per gram. The specific content of each raw material in the present embodiment is: the quality of Bailing mushroom fungus chaff powder is 190kg, the quality of potato ...

Embodiment 3

[0069] The fermented feed of Bailing mushroom chaff in this embodiment, the fermentation raw material is composed of Bailing mushroom chaff powder and rice starch, the weight ratio of Bailing mushroom chaff powder to jade starch is 20:1, and the inoculation of fermentation raw materials accounts for the weight of fermentation raw materials 8% of the bacterial liquid is then subjected to anaerobic fermentation treatment. The bacterial liquid is a mixed bacterial liquid of Candida liquid and Lactobacillus acidophilus liquid, the weight ratio of Candida liquid and Lactobacillus acidophilus liquid in the mixed liquid is 8:1, and the active bacteria in the Candida liquid The content is greater than 4.2 billion per gram, and the active bacteria content in the Lactobacillus acidophilus liquid is greater than 4 billion per gram. The specific content of each raw material in the present embodiment is: the quality of Bailing mushroom fungus chaff powder 200kg, the quality of rice starch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com