Environment-friendly efficient type puffed feed for snakeheads

A technology of extruded feed and snakehead, which is applied in animal feed, animal feed, application, etc., to reduce the probability of disease, reduce the probability of water pollution, and improve palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

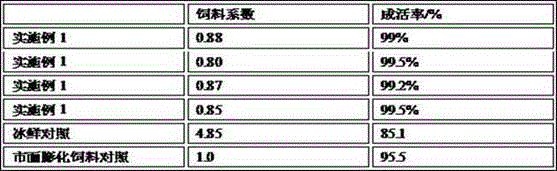

Examples

Embodiment 1

[0040] A preparation method of extruded feed for snakehead:

[0041] (1) Weigh the ingredients according to the formula, mix, crush, and sieve, and repeat twice as needed until the mixture can pass through a 100-mesh sieve;

[0042] (2) Move the raw material powder into the modulator, and pass in water vapor according to 16% of the mass of the raw material powder for modulation;

[0043] (3) Then enter the extruding and extruding granulator to make feed pellets, and dry the feed pellets at 95 degrees Celsius to obtain the finished extruded feed;

[0044] The formula is made up of the following raw materials in parts by mass:

[0045] 290 parts by mass of peeled soybean meal

[0046] 20 parts by mass of brewer's yeast

[0047] 370 parts by mass of imported fish meal

[0048] 35 parts by mass of blood meal

[0049] 25 parts by mass of corn gluten powder

[0050] Calcium dihydrogen phosphate 8 parts by mass

[0051] Yeast paste 8 parts by mass

[0052] 15 parts by mass of...

Embodiment 2

[0061] A preparation method of extruded feed for snakehead:

[0062] (1) Weigh the ingredients according to the formula, mix, crush, and sieve, and repeat twice as needed until the mixture can pass through a 100-mesh sieve;

[0063] (2) Move the raw material powder into the modulator, according to 18% of the mass of the raw material powder, pass in 95 degrees Celsius water vapor for modulation;

[0064] (3) Then enter the extruding pellet mill to make feed pellets, and dry the feed pellets at 90 degrees Celsius to obtain the finished extruded feed;

[0065] The formula is made up of the following raw materials in parts by mass:

[0066] 310 parts by mass of peeled soybean meal

[0067] 25 parts by mass of brewer's yeast

[0068] 390 parts by mass of imported fish meal

[0069] 45 parts by mass of blood meal

[0070] 30 parts by mass of corn gluten powder

[0071] Calcium dihydrogen phosphate 10 parts by mass

[0072] 12 parts by mass of yeast paste

[0073]22 parts by ...

Embodiment 3

[0082] A preparation method of extruded feed for snakehead:

[0083] (1) Weigh the ingredients according to the formula, mix, crush, and sieve, repeat 3 times as needed, until the mixture can pass through a 100-mesh sieve;

[0084] (2) Move the raw material powder into the modulator, and inject 100 degrees Celsius water vapor according to 17% of the mass of the raw material powder for modulation;

[0085] (3) Then enter the extruding pellet mill to make feed pellets, and dry the feed pellets at 100 degrees Celsius to obtain the finished extruded feed;

[0086] The formula is made up of the following raw materials in parts by mass:

[0087] 300 parts by mass of peeled soybean meal

[0088] 22 parts by mass of brewer's yeast

[0089] 380 parts by mass of imported fish meal

[0090] 40 parts by mass of blood meal

[0091] 28 parts by mass of corn gluten powder

[0092] Calcium dihydrogen phosphate 9 parts by mass

[0093] Yeast paste 11 parts by mass

[0094] 20 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com