Method for preparing biological activity glass microspheres by macroporous carbon template

A bioactive glass and macroporous carbon technology, applied in the field of biomedical materials, can solve the problems of difficult dispersion of particles, difficult to control micro-nano structure, difficult to control the size of morphological particles, and difficult to exert the micro-nano effect of materials, and achieves uniform particle size, The effect of small particle size deviation and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1(58

[0023] 1. Implementation case 1 (58S does not require sodium source)

[0024] 1. Preparation of 58S bioactive glass microspheres with different particle sizes:

[0025] (1) Stir 9.375g tetraethyl orthosilicate, 1.0875g triethyl phosphate, 7.5g absolute ethanol, 0.3g nitric acid solution (2mol / L), and 0.75g distilled water in a 50mL beaker for 2h.

[0026] (2) Add 6.375g calcium nitrate tetrahydrate to the above mixture, stir until completely dissolved.

[0027] (3) Four copies of the above solution were prepared in parallel.

[0028] (4) Immerse three-dimensionally ordered macroporous carbon templates with pore diameters of 470 nm, 350 nm, 250 nm, and 180 nm, respectively, and soak overnight.

[0029] (5) Place the 4 samples in an oven at 60°C and gel for 3 days until completely dry.

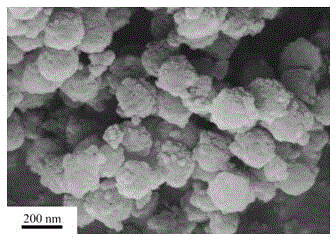

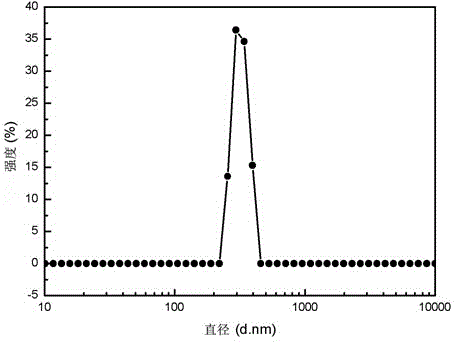

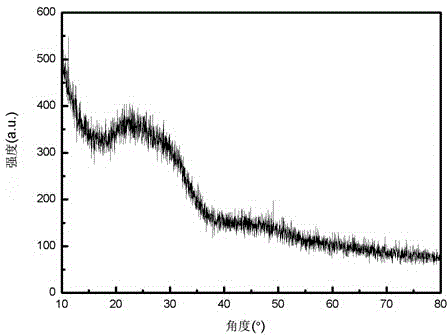

[0030] (6) Remove excess gel on the surface of the template, calcinate in a high-temperature furnace at 600°C for 3 hours, grind and ultrasonically disperse to obtain 4 parts of 58S (58% SiO ...

Embodiment example 2(68

[0044] 2. Implementation case 2 (68S does not require sodium source)

[0045] 1. Preparation of 68S bioactive glass microspheres with different particle sizes:

[0046] (1) Stir 12.23g tetraethyl orthosilicate, 1.145g triethyl phosphate, 7.5g absolute ethanol, 0.3g nitric acid solution (2mol / L), and 0.75g distilled water in a 50mL beaker for 2h.

[0047] (2) Add 4.825g calcium nitrate tetrahydrate and stir until completely dissolved.

[0048] (3) Four copies of the above solution were prepared in parallel.

[0049] (4) Immerse three-dimensionally ordered macroporous carbon templates with pore diameters of 470 nm, 350 nm, 250 nm, and 180 nm, respectively, and soak overnight.

[0050] (5) Place in an oven at 60°C for 3 days to gel until completely dry.

[0051] (6) Remove excess gel on the surface of the template, calcinate in a high-temperature furnace at 600°C for 3 hours, grind and ultrasonically disperse to obtain 68S (68%SiO 2 -23%CaO-9%P 2 o 5 , wt%) bioactive glass ...

Embodiment example 3

[0056] 1. Preparation of 45S5 bioactive glass microspheres with different particle sizes:

[0057] (1) Stir 7.812g tetraethyl orthosilicate, 0.774g triethyl phosphate, 0.8g nitric acid solution (2mol / L), and 12.15g distilled water in a 50mL beaker for 2h.

[0058] (2) Add 5.0182g of calcium chloride and 3.4g of sodium nitrate, and stir until completely dissolved.

[0059] (3) Four copies of the above solution were prepared in parallel.

[0060] (4) Immerse three-dimensionally ordered macroporous carbon templates with pore diameters of 470 nm, 350 nm, 250 nm, and 180 nm, respectively, and soak overnight.

[0061] (5) Place in an oven at 60°C for 3 days to gel until completely dry.

[0062] (6) Remove the excess gel on the surface of the template, calcinate in a high-temperature furnace at 600 °C for 3 h, grind and ultrasonically disperse to obtain 45S5 (46.1% SiO 2 -26.9%CaO-24.4%Na 2 O-2.6%P 2 o 5 , wt%) bioactive glass microsphere powder.

[0063] 2. The biological act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com