Xanthophyll perilla softgel production method

A production method and lutein technology are applied in the functions of food ingredients, food ingredients containing natural extracts, food forming, etc., which can solve the problems of easy oxidative degradation of leaf pigments, poor stability of free lutein, and extraction time. Long-term problems, to achieve the effect of lowering low-density cholesterol, delaying the development of cancer, and preventing cataracts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Lutein perilla soft capsule, its composition includes: soft capsule skin composition and content composition, described soft capsule skin composition includes gelatin, glycerin, purified water and caramel color, and described content composition includes bilberry extract , grape seed extract, lutein, β-carotene, perilla seed oil and beeswax, the parts by weight of each component are: 1-4 parts of cranberry extract, 100-120 parts of grape seed extract, leaves 15-18 parts of flavin, 1-3 parts of β-carotene, 300-350 parts of perilla seed oil, 10-18 parts of beeswax, 200-250 parts of gelatin, 110-125 parts of glycerin, 10-25 parts of caramel color and 450-500 parts of purified water.

Embodiment 2

[0031] A lutein perilla soft capsule, its composition includes: soft capsule skin composition and content composition, described soft capsule skin composition includes gelatin, glycerin, purified water and caramel color, and described content composition includes cranberry extract, grape seed extract, lutein, β-carotene, perilla seed oil and beeswax, the parts by weight of each component are: 15 parts of bilberry extract, 100 parts of grape seed extract, lutein 15 parts, β-carotene 1.5 parts, perilla seed oil 318.5 parts, beeswax 15 parts, gelatin 235 parts, glycerin 117 parts, caramel color 11.2 parts and purified water 470 parts.

Embodiment 3

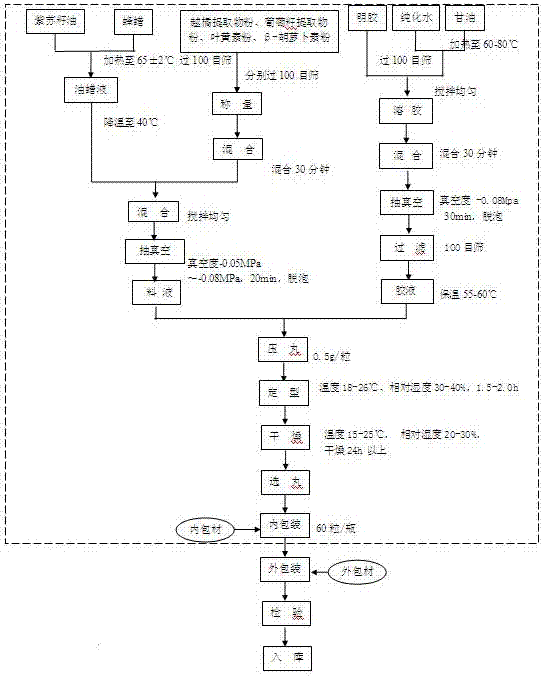

[0033] According to the production method of lutein perilla soft capsules described in Example 1, the steps of the production method are: (1) preparation of raw materials; (2) preparation of glue; (3) batching of feed liquid; (4) pressing Pills; (5) finalizing; (6) drying; (7) selecting pills; (8) packaging, inspection, and storage. The material liquid batching process is as follows: in a workshop with an air purification level of 100,000, under the condition of ensuring no pollution in the intermediate process, take the prescribed amount of beeswax and perilla seed oil in a preparation tank, and heat it to 65±2 ℃, stir to melt the beeswax completely, mix evenly to obtain oily wax liquid; then cool down to 40℃; add raw material medicine, stir evenly, stir in a vacuum emulsifier for 15-30 minutes, vacuumize to make the vacuum degree reach -0.05 MPa~-0.08MPa, stir for 20 minutes until the feed liquid has no air bubbles, and obtain the feed liquid for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com