Fiber-reinforced heat preservation and insulation material and preparation method thereof

A technology of thermal insulation and fiber reinforcement, which is applied in the fields of thermal insulation materials and their preparation, fiber reinforced thermal insulation materials and their preparation fields, and can solve the problems of poor thermal insulation effect, high thermal conductivity, poor thermal insulation performance of thermal insulation materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

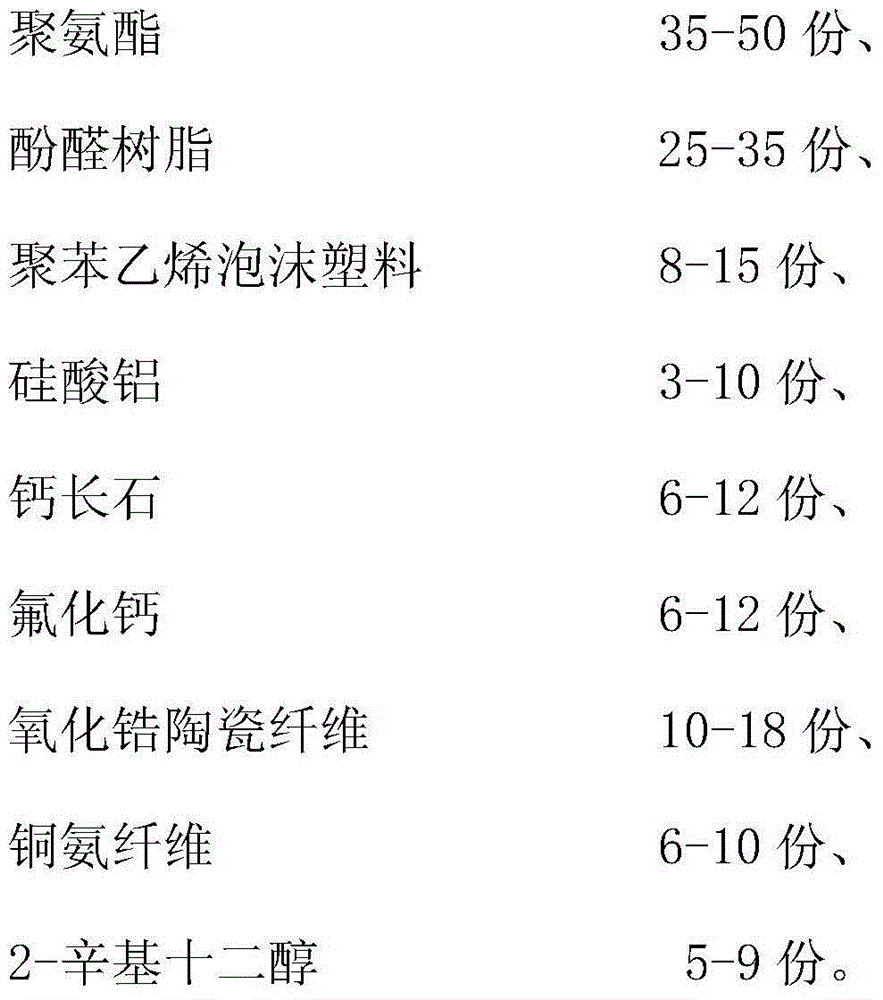

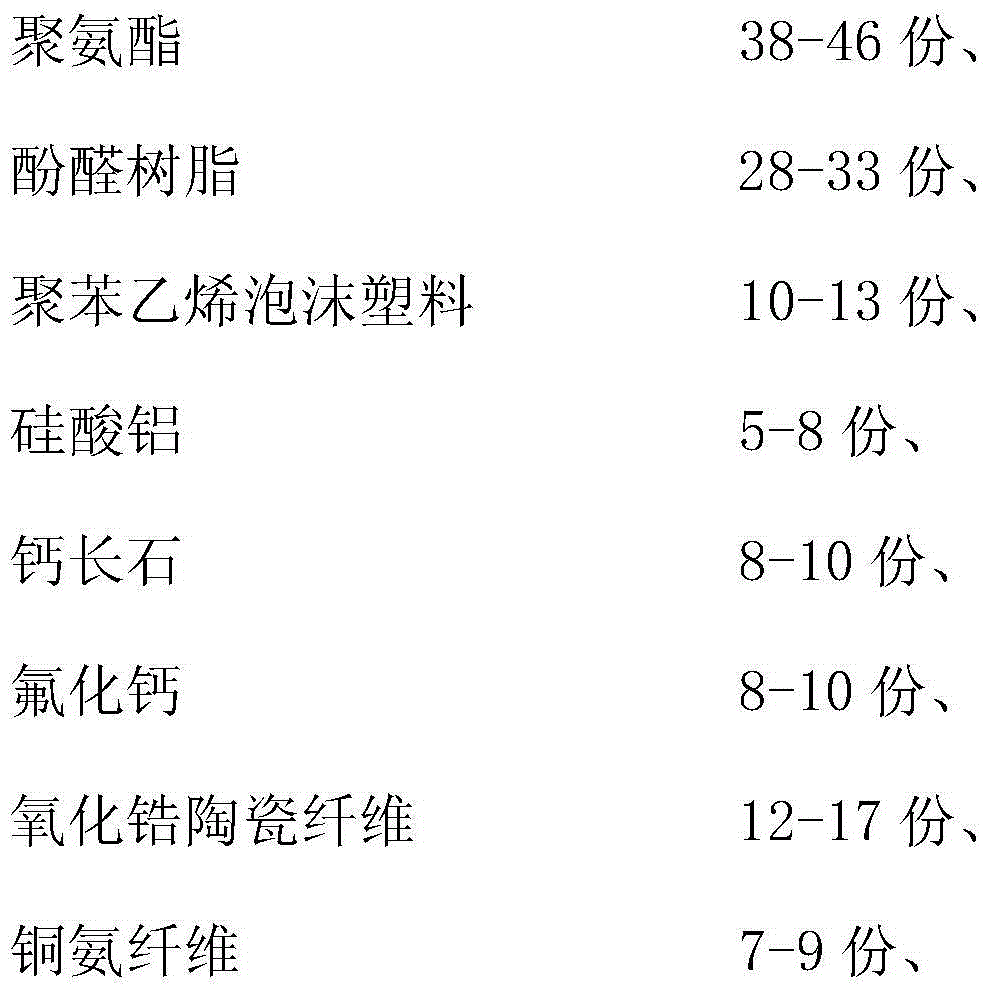

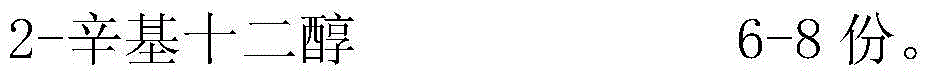

Method used

Image

Examples

Embodiment 1

[0021] (1) First, the three materials of aluminum silicate, anorthite and calcium fluoride are pulverized with a pulverizer respectively. After pulverization, the above three materials are ball milled with a ball mill. The ratio of ball to material in the ball mill is 10:1. time 1h;

[0022] (2) Take 50 parts of polyurethane, 25 parts of phenolic resin, 15 parts of polystyrene foam, 10 parts of aluminum silicate after ball milling, 6 parts of anorthite after ball milling, and 12 parts of calcium fluoride after ball milling respectively by weight , 18 parts of zirconia ceramic fiber, 6 parts of cupro ammonia fiber, and 9 parts of 2-octyldodecanol, all the above-mentioned materials are put into a high-temperature stirring tank, and the temperature of the high-temperature stirring tank is adjusted to 105 ° C. At this temperature Mechanical stirring for 50min;

[0023] (3) After stirring, put the mixed material in the high-temperature reactor into a high-temperature mold for comp...

Embodiment 2

[0025] (1) First, the three materials of aluminum silicate, anorthite and calcium fluoride are pulverized with a pulverizer respectively. After pulverization, the above three materials are ball milled with a ball mill. The ratio of ball to material in the ball mill is 5:1. The time is 3h;

[0026] (2) Take 35 parts of polyurethane, 35 parts of phenolic resin, 8 parts of polystyrene foam, 3 parts of aluminum silicate after ball milling, 12 parts of anorthite after ball milling, and 6 parts of calcium fluoride after ball milling respectively by weight , 10 parts of zirconia ceramic fiber, 10 parts of cupro ammonia fiber, and 5 parts of 2-octyldodecanol, put all the above materials into a high-temperature stirred tank, adjust the temperature of the high-temperature stirred tank to 95 ° C, at this temperature Mechanical stirring for 90min;

[0027] (3) After stirring, put the mixed material in the high-temperature reactor into a high-temperature mold for compression molding. The ...

Embodiment 3

[0029] (1) First, the three materials of aluminum silicate, anorthite and calcium fluoride are pulverized with a pulverizer respectively. After pulverization, the above three materials are ball milled with a ball mill. The ratio of ball to material in the ball mill is 10:1. time 1h;

[0030] (2) Take 38 parts of polyurethane, 33 parts of phenolic resin, 13 parts of polystyrene foam, 8 parts of aluminum silicate after ball milling, 10 parts of anorthite after ball milling, and 8 parts of calcium fluoride after ball milling respectively by weight , 12 parts of zirconia ceramic fiber, 9 parts of cupro ammonia fiber, and 6 parts of 2-octyldodecanol, all the above materials are put into a high-temperature stirred tank, and the temperature of the high-temperature stirred tank is adjusted to 105°C. Mechanical stirring for 50min;

[0031] (3) After stirring, put the mixed material in the high-temperature reactor into a high-temperature mold for compression molding. The temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com