Method and system for separating butyl acetate and n-butanol through coupling of pressure-swing distillation and heat-pump distillation

A technology of butyl acetate and heat pump rectification, which is applied in the chemical industry, can solve the problems of high energy consumption and separation difficulties, and achieve the effects of reducing consumption, independent operating conditions, and reducing circulating cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

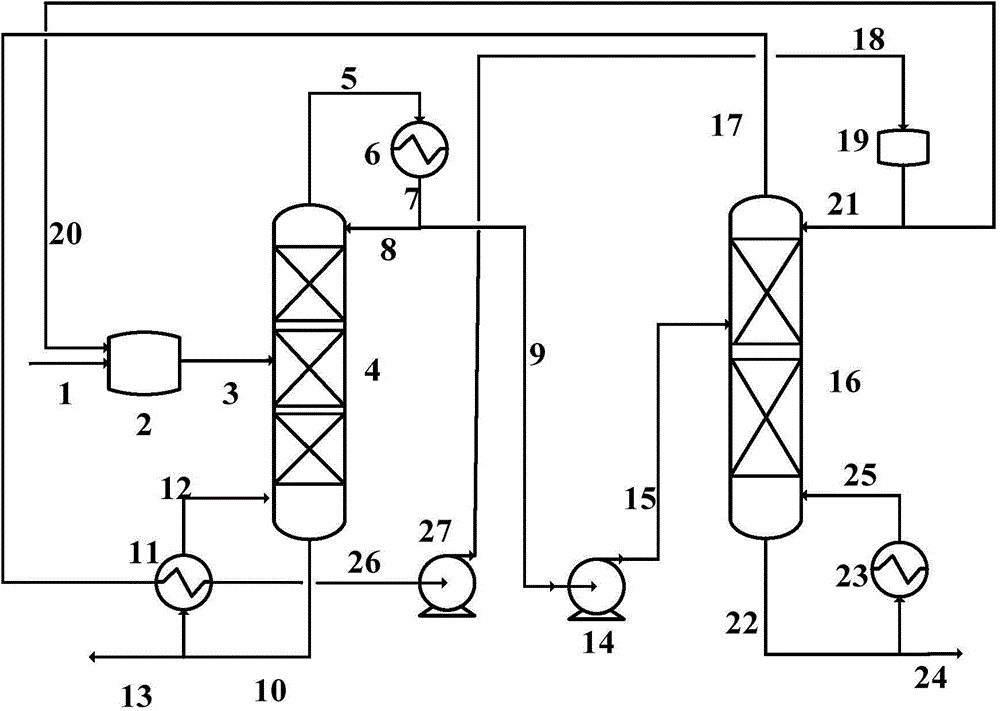

[0034] 500Y type structured packing is filled in the first rectifying tower 4, and the number of trays is 22. The feed liquid output by the mixer 2 enters the 14th tray of the first rectifying tower 4, and the operating pressure is set to 0.01MPa. The top temperature is 58.4°C, and the bottom temperature is 63.9°C. The second rectification tower 16 is filled with 500Y-type structured packing, the number of trays is 35, the feeding position of the second rectification tower 16 is the 24th tray, the operating pressure is 0.1MPa, and the tower top temperature is 115.3°C , the temperature of the tower kettle was 125.6°C.

[0035] In the feed line 1 containing butyl acetate and n-butanol raw materials, the feed rate of the feed liquid is 9514.14 kg / h, and the feed temperature is 50°C. The composition of the raw material liquid is: 61.0% of butyl acetate, 39.0% of n-butanol (mass percentage).

[0036] The azeotrope of butyl acetate and n-butanol distilled off from the top of the s...

Embodiment 2

[0041] 500Y type structured packing is filled in the first rectifying tower 4, and the number of trays is 40. The feed liquid output by the mixer 2 enters the 24th tray of the first rectifying tower 4, and the operating pressure is set at 0.01MPa. The top temperature is 58.4°C, and the bottom temperature is 64.0°C. The second rectification tower 16 is filled with 500Y-type structured packing, the number of trays is 18, the feeding position of the second rectification tower 16 is the 8th tray, the operating pressure is 0.12MPa, and the tower top temperature is 120.5°C , the temperature of the tower kettle was 131.9°C.

[0042] In the feed line 1 containing butyl acetate and n-butanol raw materials, the feed rate of the feed liquid is 10354.89 kg / h, and the feed temperature is 50°C. The composition of the raw material liquid is: 78.5% of butyl acetate, 21.5% of n-butanol (mass percentage).

[0043] The azeotrope of butyl acetate and n-butanol distilled from the butyl acetate a...

Embodiment 3

[0048] The first rectification tower 4 is filled with 500Y-type structured packing, and the number of trays is 35, wherein the feed liquid at the outlet of the mixer 2 enters the 20th tray of the first rectification tower 4, and the operating pressure is 0.02MPa. The temperature was 73.4°C, and the temperature in the bottom of the column was 78.0°C. The second rectification tower 14 is filled with 500Y-type structured packing, the number of trays is 21, the feeding position of the second rectification tower 14 is the 13th tray, the operating pressure is 0.1MPa, and the tower top temperature is 115.3°C , the temperature of the tower kettle was 125.8°C.

[0049] The feed rate of the raw material liquid containing butyl acetate and n-butanol is 9093.77 kg / h, the feed temperature is 50° C., and the composition of the raw material liquid is: 51.1% of butyl acetate and 48.9% of n-butanol. The azeotrope of butyl acetate and n-butanol distilled from the top of the second rectifying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com