Preparation method of cellulose nanometer crystal with functionalized alkynyl on surface

A technology of alkyne functionalization and nanocrystals, which is applied in the field of preparation of alkyne functionalization on the surface of cellulose nanocrystals, can solve the problems that nanocrystals are difficult to disperse, and achieve excellent matrix compatibility, low cost, and environmentally friendly preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

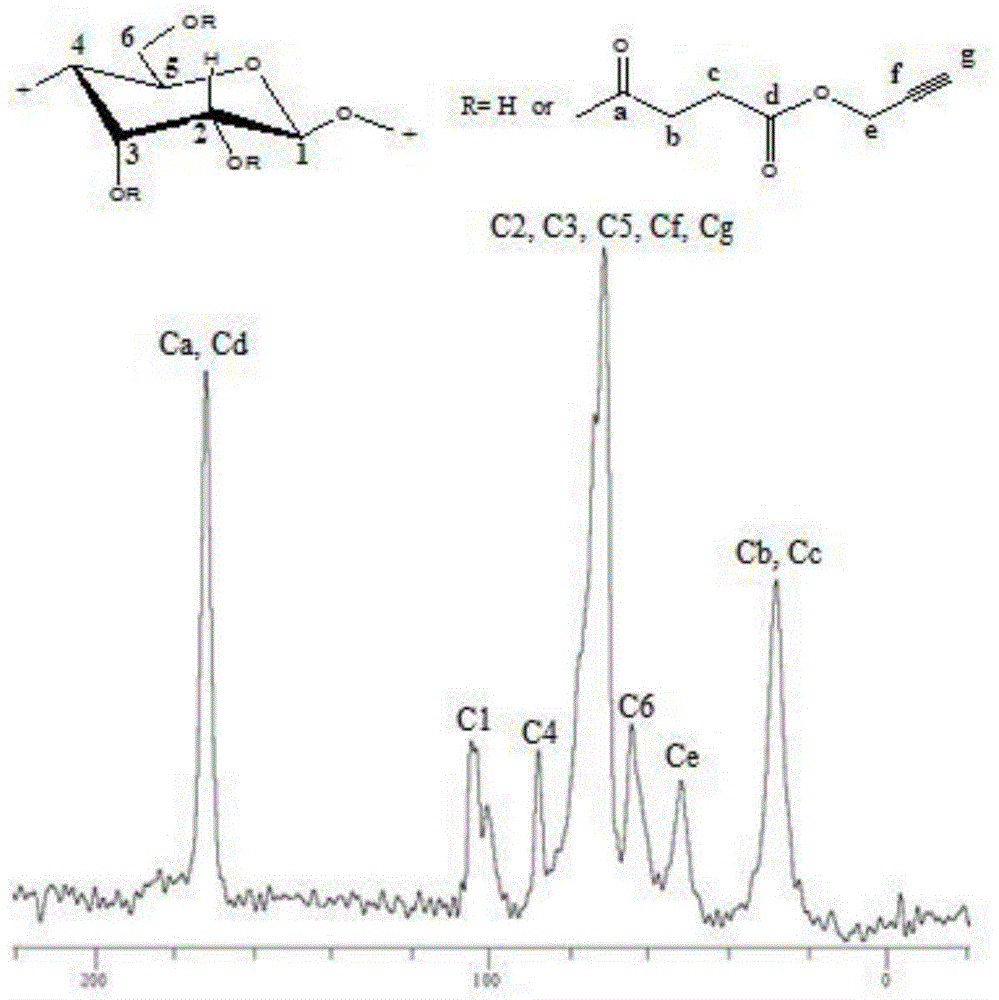

[0019] A preparation method for alkyne group functionalization on the surface of cellulose nanocrystals, comprising the steps of:

[0020] 1) Preparation of 4-oxo-4-(prop-2-yne-1-oxyl) butyric anhydride: ① propynyl alcohol (Bai Lingwei Technology Co., Ltd.), succinic anhydride (Bai Lingwei Technology Co., Ltd.) and 4-di Aminopyridine (Bailingwei Technology Co., Ltd.) was added to the solvent dichloromethane in a molar ratio of 1:1.1:0.1 and mixed, and reacted at room temperature for 36 hours; then passed through NaHSO with a mass fraction of 10% 4 Wash 3 times, MgSO 4 Dry and filter to obtain 4-oxo-4-(prop-2-yne-1-oxyl)butyric acid, the yield is 80.1%; ② press 4-oxo-4-(prop-2-yne-1- Oxygen) butanoic acid and dehydrating agent dicyclohexylcarbodiimide (Bai Lingwei Technology Co., Ltd.) molar ratio is 2:1, join in the solvent methylene chloride and mix, react at room temperature for 24 hours, filter, concentrate and finally The product 4-oxo-4-(prop-2-yne-1-oxy)butyric anhydri...

Embodiment 2

[0024] A preparation method for alkyne group functionalization on the surface of cellulose nanocrystals, comprising the steps of:

[0025] 1) Preparation of 4-oxo-4-(prop-2-yne-1-oxyl) butyric anhydride: ① propynyl alcohol (Bai Lingwei Technology Co., Ltd.), succinic anhydride (Bai Lingwei Technology Co., Ltd.) and 4-di Add methylaminopyridine (Bailingwei Technology Co., Ltd.) in a molar ratio of 1:1.1:0.2 to the solvent dichloromethane and mix, and react at room temperature for 36 hours; 4 Wash 3 times, MgSO 4 Dry and filter to obtain 4-oxo-4-(prop-2-yne-1-oxyl group) butyric acid with a yield of 82.7%; 2. press 4-oxo-4-(prop-2-yne-1- Oxygen) butanoic acid and dehydrating agent dicyclohexylcarbodiimide (Bai Lingwei Technology Co., Ltd.) molar ratio is 2:1, join in the solvent methylene chloride and mix, react at room temperature for 24 hours, filter, concentrate and finally The product 4-oxo-4-(prop-2-yne-1-oxyl)butanoic anhydride was obtained with a yield of 89.6%.

[002...

Embodiment 3

[0029] A preparation method for alkyne group functionalization on the surface of cellulose nanocrystals, comprising the steps of:

[0030] 1) Preparation of 4-oxo-4-(prop-2-yne-1-oxyl) butyric anhydride: ① propynyl alcohol (Bai Lingwei Technology Co., Ltd.), succinic anhydride (Bai Lingwei Technology Co., Ltd.) and 4-di Add methylaminopyridine (Bailingwei Technology Co., Ltd.) in a molar ratio of 1:1.1:0.1 to the solvent dichloromethane and mix, and react at room temperature for 36 hours; then pass through 10% NaHSO 4 Wash 3 times, MgSO 4Dry and filter to obtain 4-oxo-4-(prop-2-yne-1-oxyl group) butyric acid with a yield of 84.0%; ② press 4-oxo-4-(prop-2-yne-1- Oxygen) butanoic acid and dehydrating agent dicyclohexylcarbodiimide (Bai Lingwei Technology Co., Ltd.) molar ratio is 2:1, join in the solvent methylene chloride and mix, react at room temperature for 24 hours, filter, concentrate and finally The product 4-oxo-4-(prop-2-yne-1-oxy)butyric anhydride was obtained with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com