A kind of preparation method of metal organic framework/waterborne anticorrosion coating

A metal-organic framework and anti-corrosion coating technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of increased difficulty in the coating synthesis process, agglomeration, complex procedures, etc., to eliminate the decline in anti-corrosion effect and the brushing process simplistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1;

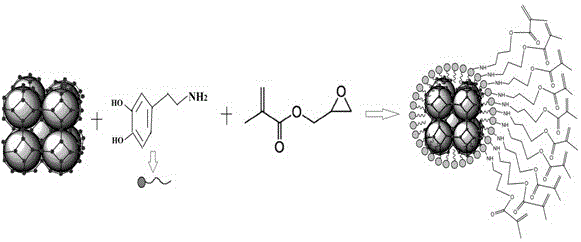

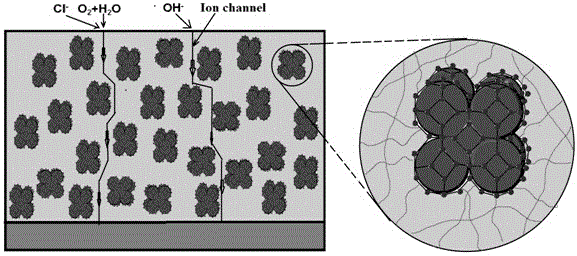

[0027] (1) Modification of metal-organic frameworks:

[0028] 1) Weigh 0.1~0.2g Tris at room temperature, dissolve it in 80~100mL water, then add 0.1~1mol / L hydrochloric acid solution to adjust the pH of the buffer solution to 8.5, weigh a certain amount of dopamine and dissolve it in the above buffer In the solution, the concentration of the dopamine buffer solution is controlled within 2 to 6 mg / mL;

[0029] 2) Put the metal-organic framework material into the buffer solution of dopamine, and place it in an ultrasonic environment for modification,

[0030] In order to obtain the metal-organic framework material loaded with dopamine.

[0031] (2) Preparation of anti-corrosion coating:

[0032] 1) Take 100 parts of water-based epoxy resin and 100 parts of water,

[0033] 2) Take 35 parts of dopamine-loaded metal-organic framework fillers, add them to the above resin system, and disperse them in a ball mill for 1 hour. Take 50 parts of water-based curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com