Polyurethane pouring sealant without settlement during long-term storage and preparation method therefor

A long-term storage and potting glue technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of settlement, reduce the use range, and unusability, and achieve the effect of ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

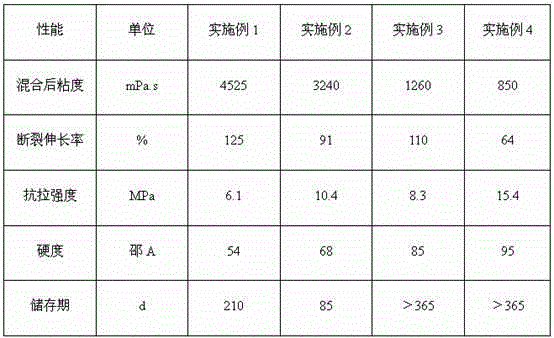

Examples

Embodiment 1

[0016] Embodiment 1: add castor oil polyol 15%Wt, polyether diol 17.5%Wt, polyether tribasic alcohol 5%Wt, dibutyl phthalate 5%Wt and sebacic acid two in the there-necked flask Octyl ester 5% Wt, heated to 100-120°C, stirred and dehydrated under vacuum for 1-2 hours, then cooled to 60°C, added to planetary stirring mixer, then added fumed silica 3.0%Wt, 0.5% Wt of the coupling agent, 0.1% Wt of the catalyst, stirred at high speed for 1 hour in a vacuum state, then added 48.9% Wt of heavy calcium carbonate, stirred for 2 hours in a vacuum state, and discharged. B component is liquefied diphenylmethane diisocyanate. According to A:B=4:1 (mass ratio), it can be used after being fully mixed.

Embodiment 2

[0017] Embodiment 2: add castor oil polyol 13%Wt, polyether diol 15%Wt, polyether tribasic alcohol 8%Wt, dibutyl phthalate 5%Wt and sebacic acid two in the there-necked flask Octyl ester 5% Wt, heated to 100-120°C, stirred and dehydrated under vacuum for 1-2 hours, then cooled to 60°C, added to planetary stirring mixer, then added organic bentonite 3.0% Wt, coupling 1.0% Wt agent, 0.1% Wt catalyst, stirred at high speed for 1 hour in a vacuum state, then added 49.9% Wt of heavy calcium carbonate, stirred in a vacuum state for 2 hours, and discharged. Component B is a mixture of 50% Wt of polymethylene polyphenyl polyisocyanate and 50% Wt of liquefied diphenylmethane diisocyanate. According to A:B=3.5:1 (mass ratio), it can be used after being fully mixed.

Embodiment 3

[0018] Embodiment 3: add castor oil polyol 10%Wt, polyether glycol 10%Wt, polyether trihydric alcohol 10%Wt, dibutyl phthalate 2%Wt and sebacic acid in there-necked flask Dioctyl ester 3% Wt, heated to 100-120°C, stirred and dehydrated under vacuum for 1-2 hours, then cooled to 60°C, added to planetary stirring mixer, and then added hydrogenated castor oil derivative liquid stream 1.5% variable aid, 1.0% Wt coupling agent, 0.2% Wt catalyst, stirred at high speed under vacuum for 1 hour, then added 62.3% Wt of heavy calcium carbonate, stirred under vacuum for 2 hours, and discharged. Component B is a mixture of 50% W t of polymethylene polyphenyl polyisocyanate and 50% W t of liquefied diphenylmethane diisocyanate. According to A:B=3:1 (mass ratio), it can be used after being fully mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com