Oil and gas field acidification high-temperature corrosion Inhibitor and preparation method thereof

A technology of high temperature corrosion inhibitor and corrosion inhibitor synergist, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc. Good acid solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

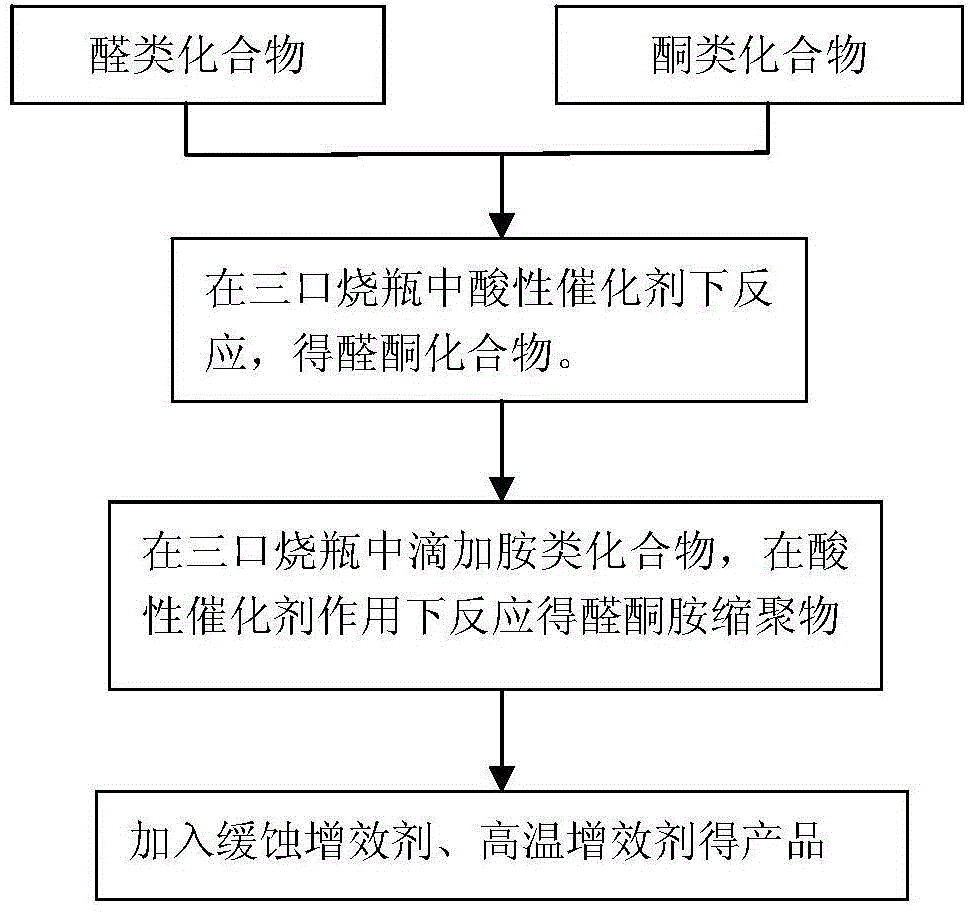

Method used

Image

Examples

Embodiment 1

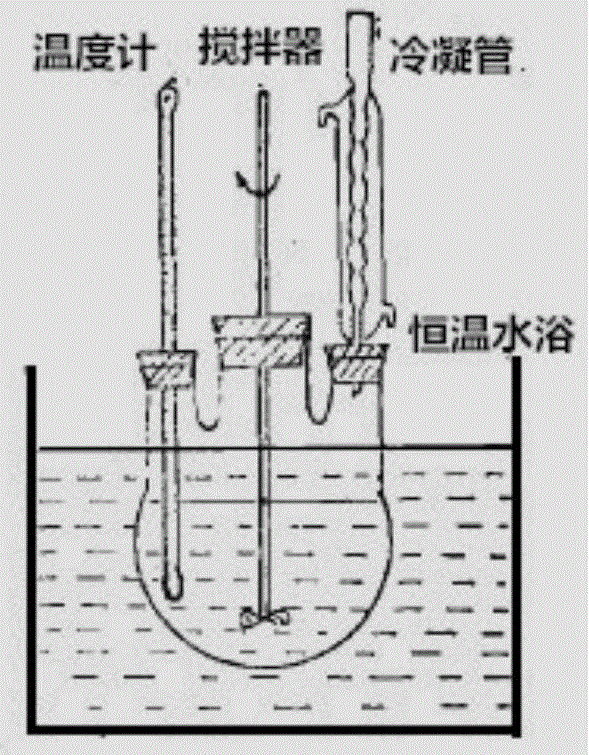

[0038] Add 317.5 grams of acetophenone and 72.2 grams of formaldehyde into a three-necked flask, add 2 milliliters of acidic catalyst (analytical grade hydrochloric acid), heat up to 90 degrees Celsius at a rate of 16 degrees Celsius / hour, keep the temperature for 5 hours, and turn on the condenser to reflux during the reaction. After the reaction is completed, let it stand for 5 hours, release the water in the lower layer, and obtain the aldehyde and ketone condensate; add 223.9 grams of aniline dropwise at 30°C, and then raise the temperature to 70°C at a rate of 16°C / hour, and keep the temperature for 6 hours, and the reaction is completed After cooling down to 30°C, the ketone aldehyde amine condensation product was obtained. Add 150 grams of aldehyde, ketone, and amine condensate, 15 grams of octynol, 25 grams of copper acetate, and 310 grams of ethanol into a 1000-milliliter ground bottle, mix well, and let stand for 1.5 hours to prepare the finished product A of high-tem...

Embodiment 2

[0040] Add 178.1 grams of cyclohexanone and 175.2 grams of benzaldehyde into a three-necked flask, add 2 milliliters of acidic catalyst (analytical grade hydrochloric acid), heat up to 90 degrees Celsius at a rate of 16 degrees Celsius / hour, keep the temperature for 5.5 hours, and open the condenser to reflux during the reaction , After the reaction was completed, let it stand for 5 hours, release the water in the lower layer, and obtain the aldehyde and ketone condensate; add 276.2 grams of propynyloxymethylaniline dropwise at 40 ° C (respectively 196.3 grams, 105.1 grams and 326.1 grams of propynyl alcohol, formaldehyde and aniline gram into a three-necked flask, then add 8.4 milliliters of analytical grade hydrochloric acid to catalyze, and react at 70° C. for 5 hours to obtain propargyloxymethylaniline), after dropping, the temperature is raised to 70° C. at a speed of 16° C. / hour, and the heat preservation reaction is carried out for 6 Hours, after the completion of the re...

Embodiment 3

[0042] Add 118.8 grams of cyclohexanone and 33.0 grams of formaldehyde into a three-necked flask, add 2 milliliters of an acidic catalyst (analytical grade hydrochloric acid), heat up to 80 degrees Celsius at a rate of 16 degrees Celsius / hour, keep the temperature for 5 hours, and turn on the condenser to reflux during the reaction. After the reaction was completed, let it stand for 5 hours, release the water in the lower layer to obtain the aldehyde and ketone condensate; add 483.1 grams of polyethylene polyamine dropwise at 35 ° C (produced by Tosoh Corporation in Japan, distributed by Shanghai Zhongyi Chemical Industry), and after the drop was completed, the mixture was cooled at 16 ° C. Raise the temperature to 75° C. at a speed of 1 hour, keep the temperature for 5 hours, and cool down to 30° C. after the reaction is completed, to obtain a ketoaldehyde amine condensate. Add 150 grams of aldehyde, ketone, and amine condensate, 25 grams of acetylene alcohol, 25 grams of copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com