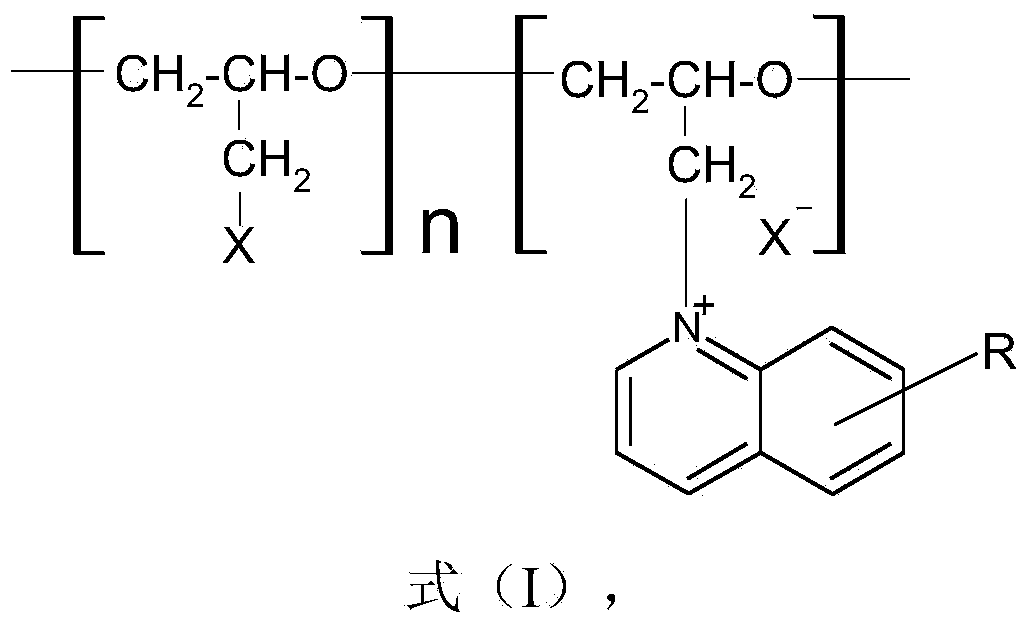

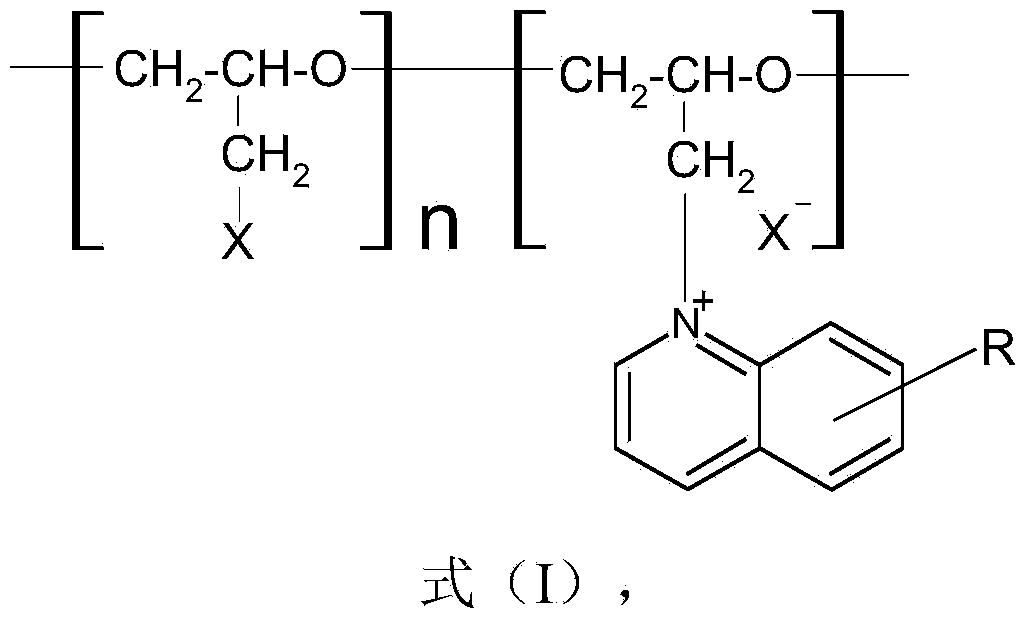

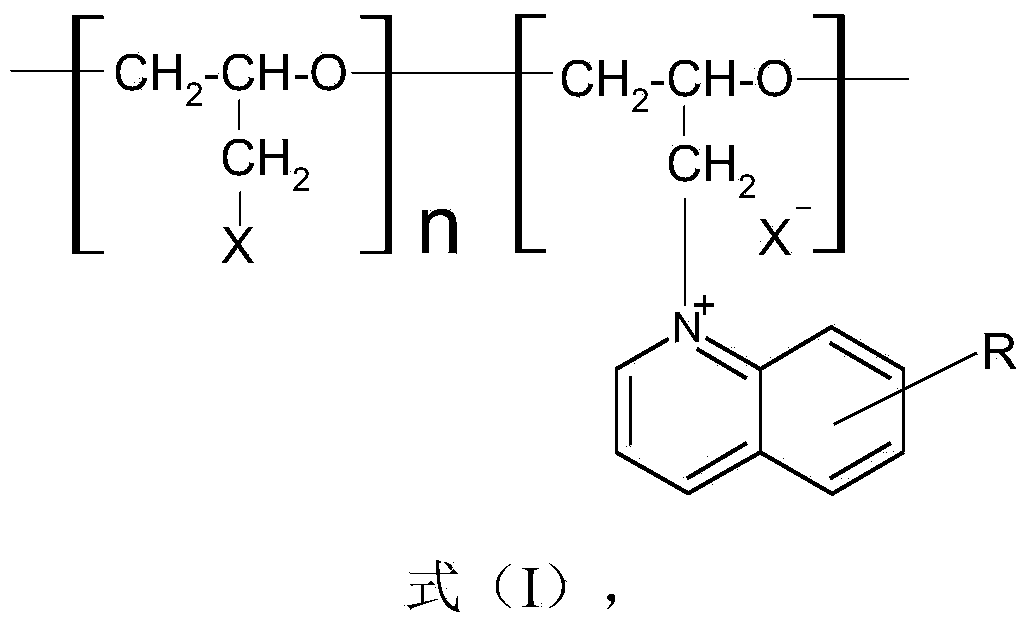

Acidizing corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and catalyst, which is applied in the fields of chemical instruments and methods, organic chemistry, earthwork drilling, etc., can solve the problems of poor corrosion inhibition effect, poor acid solubility and water solubility, etc. Remarkable etching effect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the acidified corrosion inhibitor comprises the following steps:

[0030] (1) the initiator, the catalyst and the halogenated propylene oxide are uniformly mixed at 20°C to 40°C, and reacted for 5 hours to 10 hours to obtain the reaction product;

[0031] (2) adding a quinoline derivative to the reaction product obtained in step (1) and mixing evenly, condensing and refluxing at 120°C to 180°C for 8 hours to 10 hours, to prepare the acidified corrosion inhibitor;

[0032] The mass ratio of the initiator, catalyst, halogenated propylene oxide and quinoline derivative is 2~4:1~2:50~100:10~30, preferably 2.5~3:1~1.5:50~80 : 25 to 30.

[0033] The initiator is an alcohol, preferably a mixture of one or more of methanol, ethanol, isopropanol, ethylene glycol, propylene glycol and glycerol, more preferably ethylene glycol.

[0034] The catalyst is a mixture of one or more of boron trifluoride, tetrahydrofuran, phosphorus hexafluoride, triethyl oxys...

Embodiment 1

[0039] The preparation method of the acidified corrosion inhibitor comprises the following steps:

[0040] (1) the initiator, the catalyst and the halogenated propylene oxide are uniformly mixed at 20° C. and reacted for 5 hours to obtain the reaction product;

[0041] (2) adding a quinoline derivative to the reaction product obtained in step (1) and mixing uniformly, condensing and refluxing at 120° C. for 8 hours to obtain product A, that is, preparing the acidified corrosion inhibitor;

[0042] The mass ratio of the initiator, catalyst, halogenated propylene oxide and quinoline derivative is 2:1:50:10.

[0043] The initiator is methanol; the catalyst is boron trifluoride diethyl ether; the halogenated propylene oxide is epibromopropane; and the quinoline derivative is quinoline.

Embodiment 2

[0045] The preparation method of the acidified corrosion inhibitor comprises the following steps:

[0046] (1) the initiator, the catalyst and the halogenated propylene oxide are uniformly mixed at 30 ° C and reacted for 7 hours to obtain the reaction product;

[0047] (2) adding a quinoline derivative to the reaction product obtained in step (1) and mixing uniformly, condensing and refluxing at 160° C. to obtain product B, that is, preparing the acidified corrosion inhibitor;

[0048] The mass ratio of the initiator, the catalyst, the halogenated propylene oxide and the quinoline derivative is 4:1:50:25.

[0049] The initiator is ethylene glycol; the catalyst is triethoxy salt; the halogenated propylene oxide is epiiodopropane; the quinoline derivative is quinoline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com