Processing method of apple vinegar

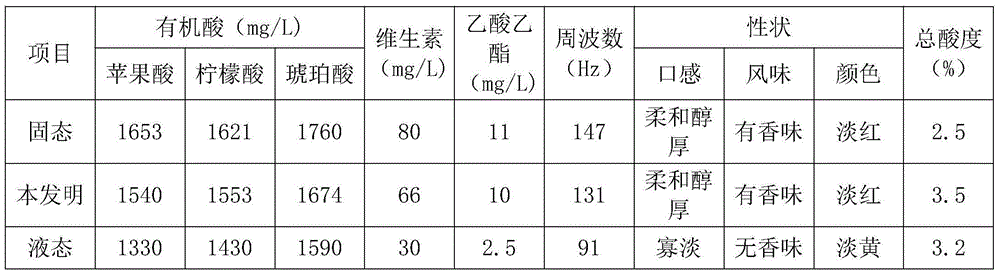

A production method and apple cider vinegar technology, which is applied in the field of fruit vinegar processing, can solve the problems of long solid-state fermentation period and poor quality of liquid-state fermentation, and achieve the effects of retaining nutritional value, convenient operation and shortening the liquid-state fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production method of apple cider vinegar, comprises the following steps:

[0018] 1) Dilute the concentrated apple juice with water, adjust the sugar content to 14Brix, add 0.03% yeast and 1.5% alcohol to the apple juice mass, keep the temperature at 33°C, and ferment for 3 days to obtain apple wine;

[0019] 2) Acetic acid fermentation: Acetic acid bacteria are carried out in primary seed tanks and secondary seed tanks to expand cultivation to obtain acetic acid bacteria liquid, which is inoculated into a fermenter equipped with cider, and the inoculum is 5% of the volume percentage of the fermenter. under fermentation;

[0020] 3) Adding of wine vinegar: add semi-finished wine vinegar with a volume percentage of 15% to the fermented liquid, ferment for 35 hours at 33°C, the acetic acid content is 4.3g / 100ml, and when the alcohol content is less than 0.4%, the fermentation ends and the obtained Apple cider vinegar finished product; the production process of ...

Embodiment 2

[0024] A kind of production method of apple cider vinegar, comprises the following steps:

[0025] 1) Dilute the concentrated apple juice with water, adjust the sugar content to 16Brix, add 0.03% yeast and 1.5% alcohol to the apple juice mass, keep the temperature at 36°C, and ferment for 5 days to obtain apple wine;

[0026] 2) Acetic acid fermentation: Acetic acid bacteria are carried out in primary seed tanks and secondary seed tanks to expand cultivation to obtain acetic acid bacteria liquid, which is inoculated into a fermenter equipped with cider, and the inoculum is 7% of the volume percentage of the fermenter. under fermentation;

[0027] 3) Adding of wine vinegar: add semi-finished wine vinegar with a volume percentage of 25% to the fermented liquid, ferment for 45 hours at 36°C, the acetic acid content is 7.1g / 100ml, and when the alcohol content is less than 0.4%, the fermentation ends, and the obtained Apple cider vinegar finished product; the production process of...

Embodiment 3

[0031] A kind of production method of apple cider vinegar, comprises the following steps:

[0032] 1) Dilute the concentrated apple juice with water, adjust the sugar content to 15Brix, add 0.03% yeast and 1.5% alcohol to the apple juice mass, keep the temperature at 34°C, and ferment for 4 days to obtain apple wine;

[0033] 2) Acetic acid fermentation: Acetic acid bacteria are carried out in primary seed tanks and secondary seed tanks to expand cultivation to obtain acetic acid bacteria liquid, which is inoculated into fermenters equipped with cider. under fermentation;

[0034] 3) Adding of wine vinegar: add semi-finished wine vinegar with a volume percentage of 20% to the fermented liquid, ferment for 40 hours at 35°C, the acetic acid content is 6.4g / 100ml, and when the alcohol content is less than 0.4%, the fermentation ends, and the obtained Apple cider vinegar finished product; the production process of the semi-finished wine vinegar is: 35 hours of acetic acid ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com