Method and device for controlling crystal orientation in steady-state magnetic field through directional solidification

A technology of directional solidification and crystal orientation, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as easy growth, and achieve the effect of simple method, convenience and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

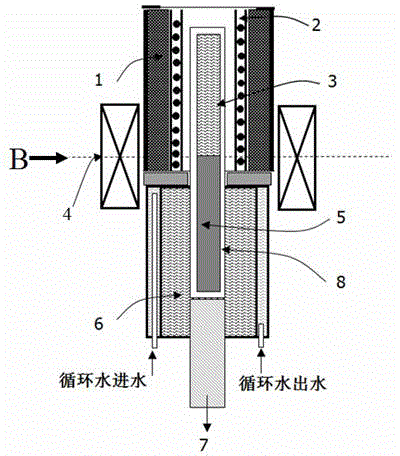

[0021] In this example, see Figure 1 ~ Figure 3 , a directional solidification device, composed of a water-cooled jacket 1, a heating furnace 2, a cooling pool 6, a tie rod 7 and a directional solidification crucible 8, the directional solidification crucible 8 adopts a corundum tube, and corundum has excellent refractoriness and thermal shock resistance, The directional solidification crucible 8 with the metal rod placed inside is set in the heating furnace 2, and the outer side of the heating furnace 2 is equipped with a water-cooled jacket 1, and a temperature control device is provided to control the temperature of the heating furnace 2. The pull rod 7 and the directional solidification crucible 8 Connected, the cooling pool 6 is located below the heating furnace 2, and a magnet 4 is also provided on the outside of the water-cooled jacket 1. The magnet 4 adopts a superconducting strong magnet, and the magnetic field direction of the stable magnetic field generated by the m...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

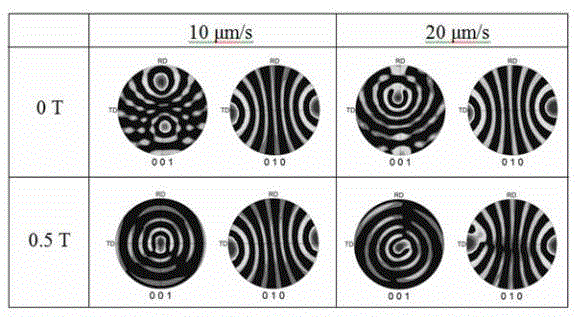

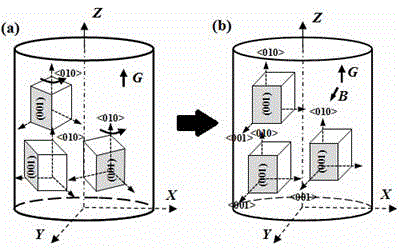

[0030] In this example, see figure 2 , a method for directional solidification to control crystal orientation under a steady magnetic field, the specific implementation steps are as follows:

[0031] a. This step is identical with embodiment one;

[0032] b. Put the vertical directional solidification device into the electromagnet that can generate a horizontal magnetic field, connect the corundum tube to the pull rod of the directional solidification device, so that it can be pulled in the heating furnace for vertical movement; turn on the electromagnet to generate 0.5 T Transverse magnetic field, heat to 900°C to melt the alloy and keep it warm for 0.5 hours, then turn on the drawing system to perform directional drawing at a set pulling speed of 20 μm / s, and ensure that the solid-liquid interface is in a stable magnetic field area during the drawing process; After the drawing is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com