Apparatus of increasing coherent beam combination laser beam quality

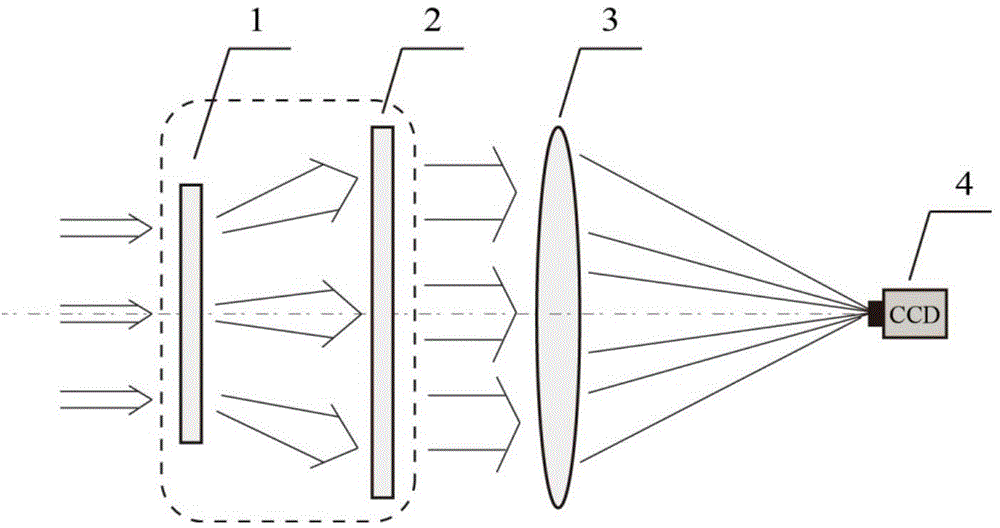

A technology of laser beam quality and coherent beam combining, applied in optics, optical components, instruments, etc., can solve the problems of non-linear effects of fiber thermal damage, difficulty in designing and manufacturing lens groups, limited focusing power density, etc. The processing technology is mature, the effect of avoiding damage to optical components and avoiding air breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

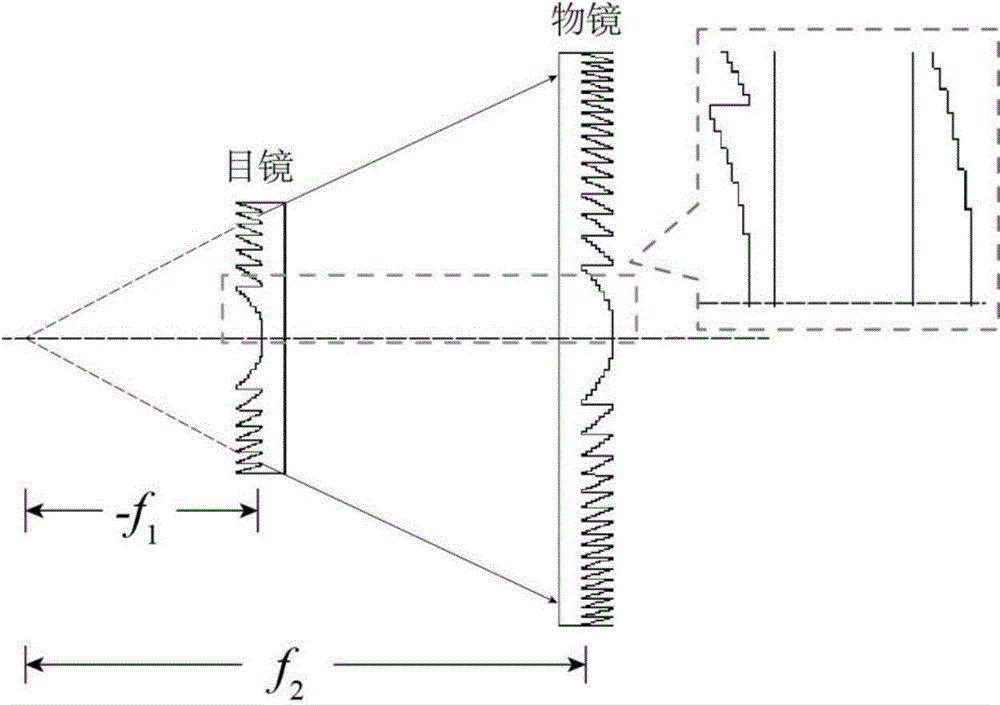

[0038] The apertures of the unit eyepiece and objective are 2R respectively 1 =5mm, 2R 2 =14mm, the focal length is f respectively 1 =-37.5mm, f 2 =105mm. The focal length of the focusing lens is f=1000 mm.

[0039] The phase steps of the fixed eyepiece array and the objective lens array are taken as L=8.

[0040] Figure 5 is the far-field spot distribution of the coherent combined beam. It can be seen that the number of side lobes in the combined beam spot is small, and the surrounding power ratio can be calculated as BQ=1.489.

[0041] As a comparison, Image 6 The far-field spot distribution of the coherent combined beam obtained directly without adding the diffractive telescopic system array is given. Compared Figure 5 It can be seen that the number of side lobes in the combined beam spot is significantly larger, and the surrounding power ratio can be calculated as BQ=3.0225. It can be seen that the use of the 8-step diffractive telescopic system array improves...

Embodiment 2

[0043] The same structural parameters as in Example 1 are adopted, that is, the apertures of the unit eyepiece and the objective lens are respectively 2R 1 =5mm, 2R 2 =14mm, the focal length is f respectively 1 =-37.5mm, f 2 =105mm. The focal length of the focusing lens is f=1000 mm.

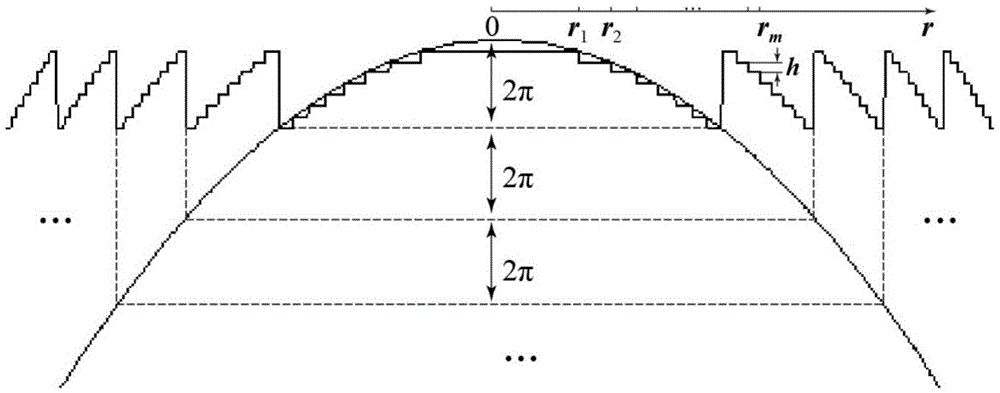

[0044] The number of phase steps in different regions is taken as different values, that is, the number of steps in the 5 annular bands in the center of the lens is 32, the number of steps in the 25 outer annular bands is 16, and the number of steps in other annular bands is 8, such as Figure 7 shown.

[0045] Figure 8 Given this surface structure, the far-field coherent combined beam spot distribution is given, and the surrounding power ratio can be calculated as BQ=1.2583. It can be seen that the number of side lobes is further reduced, and the beam quality is improved by 2.4 times compared with the case where the diffractive telescopic system array is not added, and compared with the 8-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com