Miniature ultrahigh frequency anti-metal multipurpose RFID label antenna

An RFID tag, anti-metal technology, applied in the direction of antenna support/installation device, radiating element structure, etc., can solve the problems of easy damage, poor performance, inconvenience, etc., and achieve flexible adjustment ability, good working performance, and expansion The effect of working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

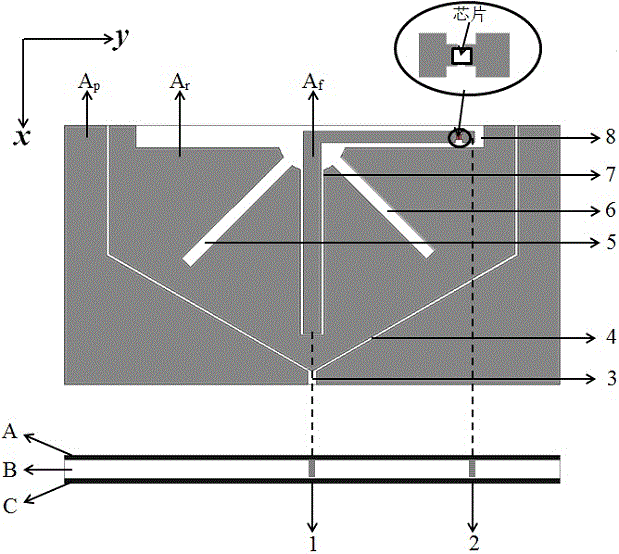

[0031] see figure 1 , The miniaturized ultra-high frequency anti-metal multi-purpose RFID tag antenna includes three layers of metal patch A, dielectric material B and metal film C from top to bottom. The metal patch A contains the main radiation patch A r , parasitic patch A p , L-type feeder A f and other structures. It is characterized by:

[0032] 1) The L-shaped feeder A f It is a non-equal-width L-shaped feeder that is wider in the longitudinal direction than in the transverse direction, and its longitudinal and transverse ends are respectively grounded through short-circuit pin 1 and short-circuit pin 2, and a label chip is connected to the transverse end;

[0033] 2) The main radiation patch A r Presents the outline of half a regular hexagon, the main radiation patch A r outside is the parasitic patch A p , parasitic patch A p and main radiation patch A r There is a gap between 4, parasitic patch A p There is a gap 3 at the middle end;

[0034] 3) The main ...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0039] 1) The main radiation patch A r and parasitic patch A p is fully enclosed;

[0040] 2) The size of the dielectric material B is larger than that of the metal patch A;

[0041] 3) When used on the surface of metal products, the metal film C may not be present.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, and the special feature is as follows: the working performance of the antenna on the surface of five common materials, namely dry wood, paper, hard rubber, quartz glass and porcelain products, and other non-metallic products.

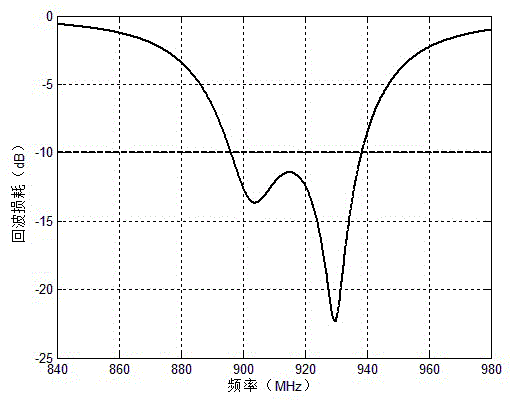

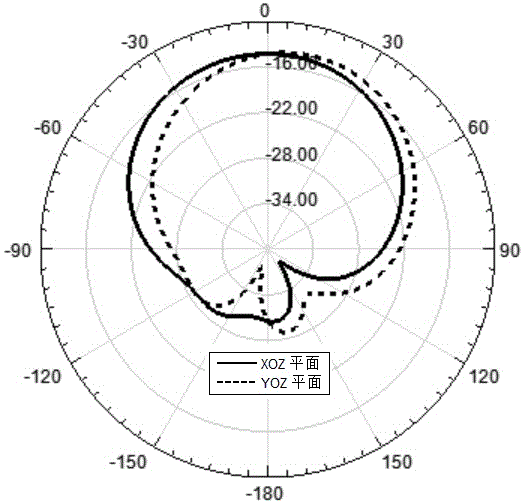

[0044] Figure 5~7 Performance parameters of the antenna on the surface of the above article are shown. Figure 5 The return loss parameters of the antenna on the above material items are shown, Image 6 with Figure 7 The antenna pattern at 910MHz and 920MHz are shown respectively. Antenna gain increases with the increase of material permittivity. Within the range of the dielectric constant of the above materials (ε r=2~4), the main axis gains of the antenna at 910MHz and 920MHz are -17~-13dBi and -13~-11dBi respectively. The antenna can meet the return loss requirements of the 902MHz~928MHz band when placed on the above-mentioned material items, and the pattern shows that the antenna h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com