Concentrating photoelectric conversion device and method of manufacturing the same

A technology of photoelectric conversion device and manufacturing method, which is applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., and can solve problems such as inability to obtain power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

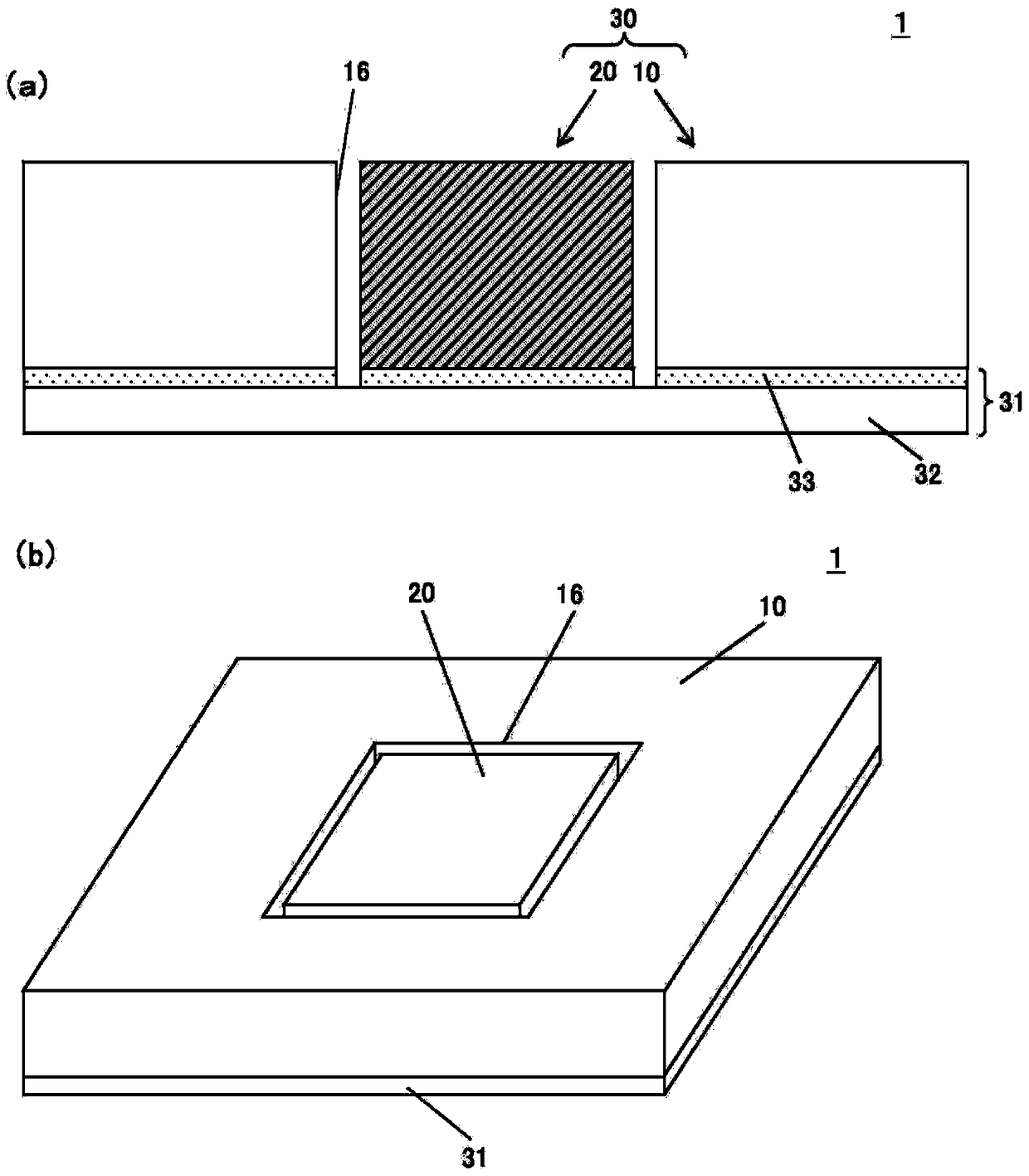

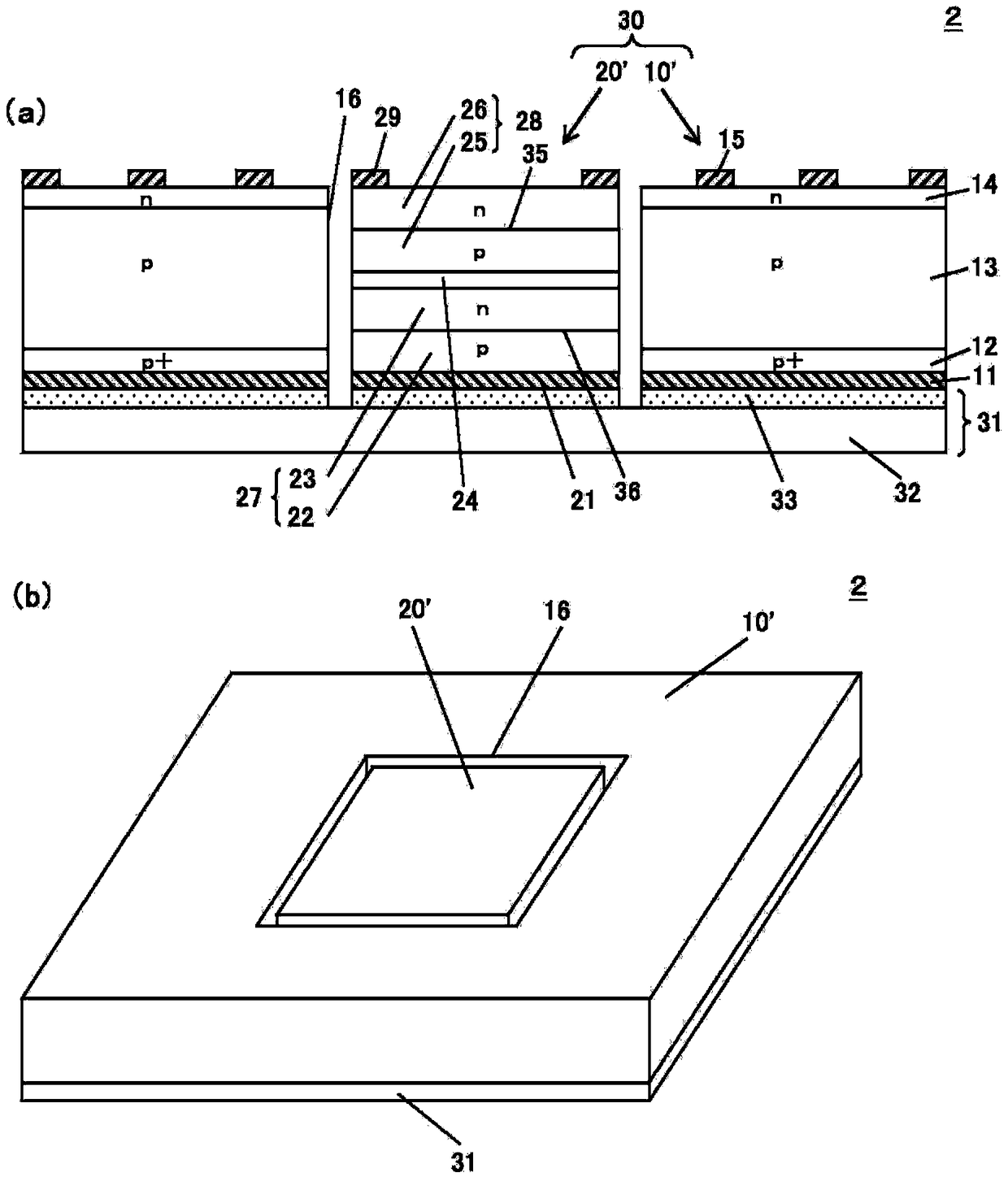

[0201] First, a silicon solar cell 10' in which through-holes 16 are formed by etching is prepared.

[0202] Next, using solder paste, the silicon solar cell 10' and the group III-V multi-junction solar cell 20' mounted on the external connection substrate 31, that is, the PCB substrate, the group III-V multi-junction solar cell 20' It is placed in the through hole 16 part of the silicon solar cell 10'.

[0203] Next, UV ozone treatment is performed.

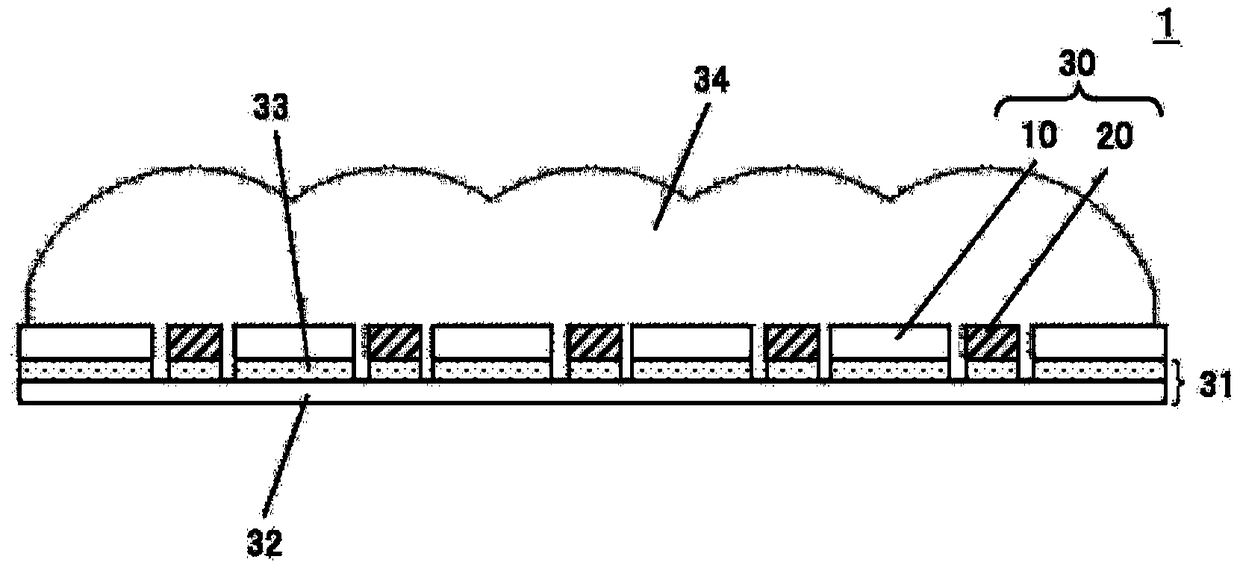

[0204] Next, the photoelectric conversion element 30 and the external connection substrate 31 were arranged in a mold, and a silicone resin (LPS-3541 (model number): manufactured by Shin-Etsu Chemical Co., Ltd.) was compression-molded. The condenser lens 34 is integrally formed to manufacture the condenser photoelectric conversion device 2 .

Embodiment 2

[0206] First, a silicon solar cell 10' in which through-holes 16 are formed by etching is prepared.

[0207] Next, using solder paste, the silicon solar cell 10' and the group III-V multi-junction solar cell 20' mounted on the external connection substrate 31, that is, the PCB substrate, the group III-V multi-junction solar cell 20' It is placed in the through hole 16 part of the silicon solar cell 10'.

[0208] Next, UV ozone treatment is performed.

[0209] Next, using a vacuum laminator (manufactured by Nichigo-Morton Co., Ltd.), a resin film prepared by mixing silicone resin (AF-500 (model): Shin-Etsu Chemical Industry Co., Ltd.) and phosphor is attached to the silicon solar cell 10' s surface.

[0210] Next, the photoelectric conversion element 30 connected to the external connection substrate 31 is placed in a mold, and the condenser lens 34 is integrally molded by compression molding silicone resin (LPS-3541 (model number): manufactured by Shin-Etsu Chemical Co., Ltd....

Embodiment 3

[0212] First, a silicon solar cell 10' in which through-holes 16 are formed by etching is prepared.

[0213] Next, using solder paste, the silicon solar cell 10' and the group III-V multi-junction solar cell 20' mounted on the external connection substrate 31, that is, the PCB substrate, the group III-V multi-junction solar cell 20' It is placed in the through hole 16 part of the silicon solar cell 10'.

[0214] Next, UV ozone treatment is performed.

[0215] Next, a material obtained by mixing polysilazane and a phosphor is coated on the surface of the silicon solar cell 10' by spin coating, and cured to form a vitreous layer.

[0216] Next, the photoelectric conversion element 30 connected to the external connection substrate 31 is placed in a mold, and the condenser lens 34 is integrally molded by compression molding silicone resin (LPS-3541 (model number): manufactured by Shin-Etsu Chemical Co., Ltd.). Light type photoelectric conversion device 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com