Peeling method of walnut kernels

A walnut kernel and peeling technology is applied in the field of peeling walnut kernels, which can solve the problems of less quality loss, large water consumption, and damage to personnel health, and achieve the effects of less environmental pollution, less nutrient loss, and less damage risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

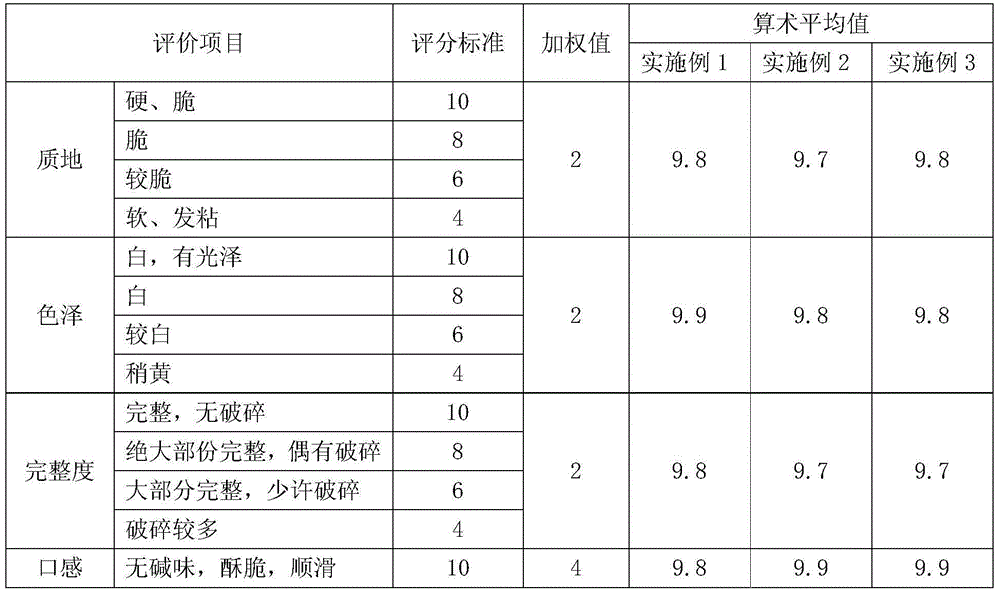

Embodiment 1

[0031] A method for peeling walnut kernels, comprising the following steps:

[0032] Select an appropriate amount of walnut kernels that are free from diseases and insect pests, mildew-free, plump and complete, and put into them containing 0.75wt% NaHCO 3 solution in the immersion tank, NaHCO 3 The temperature of the solution was 95°C, and the soaking time was 10 minutes.

[0033] The walnut kernels soaked in the lye are transported to the ice water immersion tank through the conveyor belt, the temperature of the ice water is -5°C, and the immersion time is 5 minutes.

[0034] The walnut kernels soaked in ice water are transported to the drum washing machine by the conveyor belt for washing and peeling. The rotation speed is 30r / min, the washing water pressure is 10bar, and the material stays in the drum washing machine for 3 minutes.

[0035] Rinse the peeled walnuts with normal temperature water to remove residual NaHCO 3 and seed coat, the rinsing time is 5min.

[0036]...

Embodiment 2

[0039] A method for peeling walnut kernels, comprising the following steps:

[0040] Select an appropriate amount of walnut kernels that are free from diseases and insect pests, mildew-free, plump and complete, and put into them containing 1.0wt% NaHCO 3 solution in the immersion tank, NaHCO 3 The temperature of the solution is 90° C., and the soaking time is 12 minutes.

[0041] The walnut kernels soaked in the lye are transported to the ice water immersion tank through the conveyor belt, the temperature of the ice water is -2°C, and the immersion time is 7 minutes.

[0042] The walnut kernels soaked in ice water are transported to the drum washing machine by the conveyor belt for washing and peeling. The rotation speed is 50r / min, the washing water pressure is 7bar, and the material stays in the drum washing machine for 4 minutes.

[0043] Rinse the peeled walnuts with normal temperature water to remove residual NaHCO 3 and seed coat, the rinsing time is 8min.

[0044] T...

Embodiment 3

[0047] A method for peeling walnut kernels, comprising the following steps:

[0048] Select an appropriate amount of walnut kernels that are free from diseases and insect pests, mildew, plump and complete, and add 1.2% NaHCO 3 solution in the immersion tank, NaHCO3 The temperature of the solution was 88° C., and the soaking time was 15 minutes.

[0049] The walnut kernels soaked in the lye are transported to the ice water immersion tank through the conveyor belt, the temperature of the ice water is 0°C, and the immersion time is 8 minutes.

[0050] The walnut kernels soaked in ice water are transported to the drum washing machine by the conveyor belt for washing and peeling. The rotation speed is 60r / min, the washing water pressure is 5bar, and the material stays in the drum washing machine for 5 minutes.

[0051] Rinse the peeled walnuts with normal temperature water to remove residual NaHCO 3 and seed coat, the rinsing time is 10min.

[0052] The rinsed walnut kernels are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com