Application of butadiene-b-isoprene polymer

A technology of isoprene and polyisoprene, which is applied in the field of modified polymer synthesis, can solve problems such as poor surface gloss, and achieve the effects of uniform distribution, increased rubber volume fraction, and excellent rubber properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

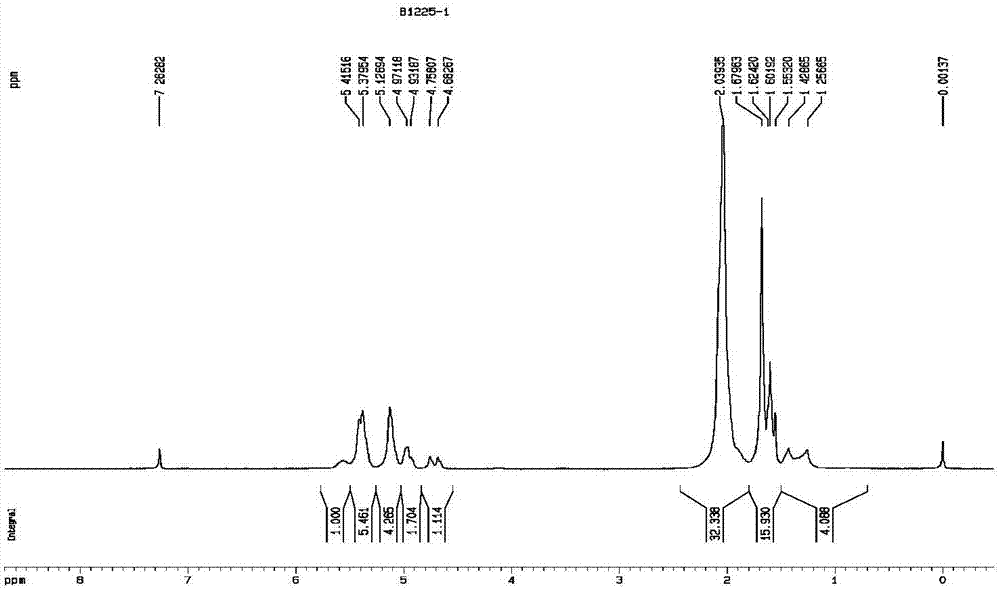

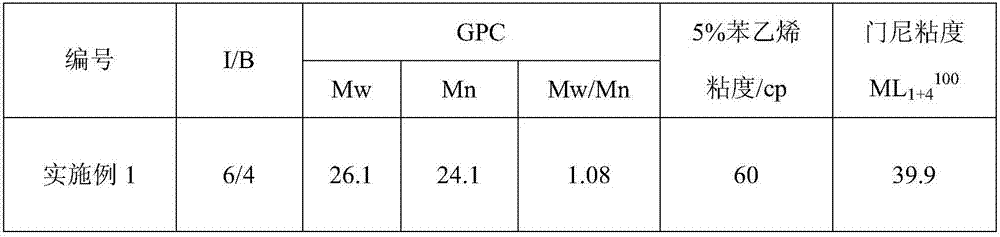

Embodiment 1

[0043]In a 5L jacketed stainless steel polymerization kettle replaced with nitrogen, introduce 2500mL of purified cyclohexane, add 0.5mL of 0.2mol / L ditetrahydrofurfurylpropane and 1.25mmol of n-butyllithium and stir, and use a jacket Heat the hot water to 70-80°C, add 265mL of isoprene for one stage of polymerization until the basic reaction of the monomer is complete, then add 194mL of butadiene for the second stage of polymerization until the monomer is completely reacted, then add 0.06g of ethanol Terminate the polymerization reaction. Put the glue out of the polymerization kettle, add 0.75g of antioxidant 1076 and 0.75g of antioxidant 168, stir evenly, and conduct drying treatment after water precipitation and coagulation to obtain dry polymer glue. GPC chromatographic test obtains that the number-average molecular weight of this polymer is 240,000, the polyisoprene segment content is 60% (mass percentage), and the polybutadiene segment content is 40% (mass percentage), a...

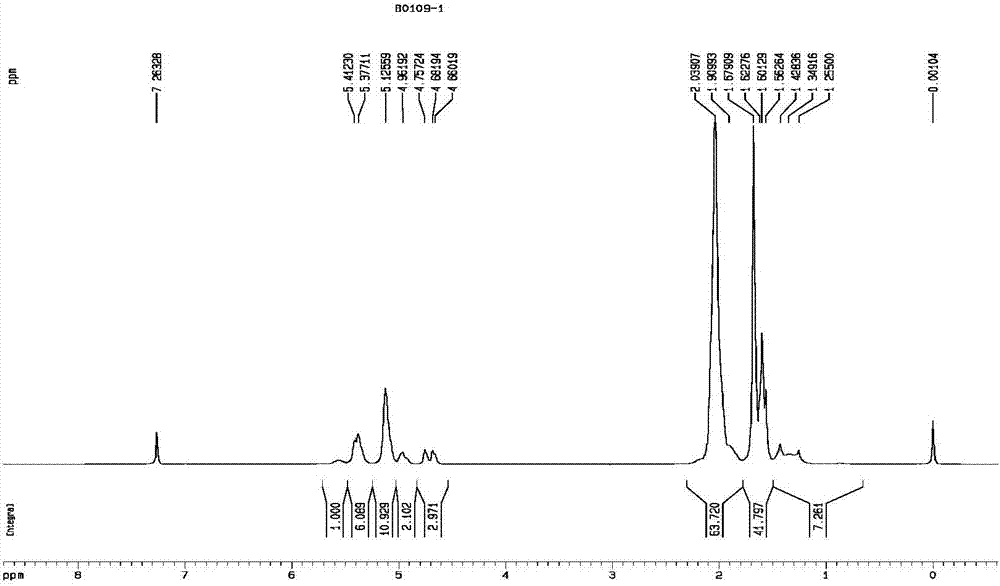

Embodiment 2

[0054] In a 5L jacketed stainless steel polymerization kettle replaced with nitrogen, introduce 2500mL of purified cyclohexane, add 0.5mL of 0.2mol / L ditetrahydrofurfurylpropane and 4.28mmol of n-butyllithium and stir, and use a jacket Heat the hot water to 60-70°C, add 194mL of butadiene to carry out a first-stage polymerization reaction until the monomer reaction is complete, then add 265mL isoprene for the second-stage polymerization reaction until the monomer reaction is complete, add 2.7mL0.4mol / L SiCl 4 Coupling was carried out, and after the coupling reaction was completed, 0.06 g of ethanol was added to terminate the polymerization reaction.

[0055] Put the glue out of the polymerization kettle, add 0.75g of antioxidant 1076 and 0.75g of antioxidant 168, stir evenly, and conduct drying treatment after water precipitation and coagulation to obtain dry polymer glue. GPC chromatographic test obtains that the single-arm number-average molecular weight of this polymer is...

Embodiment 3

[0057] In the 500mL there-necked flask equipped with agitator, reflux condenser and nitrogen protection, add the butylpentyl polymer colloid sample, styrene, ethylbenzene etc. synthesized in Example 1, wherein ethylbenzene is diluent (accounting for monomer total mass 20% of the total mass), the rubber content is 8% of the total mass, stir vigorously, add the initiator benzoyl peroxide BPO after the system is evenly mixed, react at 85°C for 6h, then heat up to 135°C for 2h, and heat Initiate further increases in conversion rates. Finally, it was devolatilized at 135°C for 2h. After the reaction is completed, the material is discharged, cut into pieces and cooled, and pumped in a vacuum oven at 40°C until the mass is constant, and its performance is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com