Light and long-service-life tundish cover and manufacturing method thereof

A manufacturing method and tundish technology, applied in the direction of manufacturing tools, casting equipment, casting molten material containers, etc., can solve the problems of low service life of the tundish cover and complex process, etc., achieve small volume expansion rate, and avoid easy burning bad, slow erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

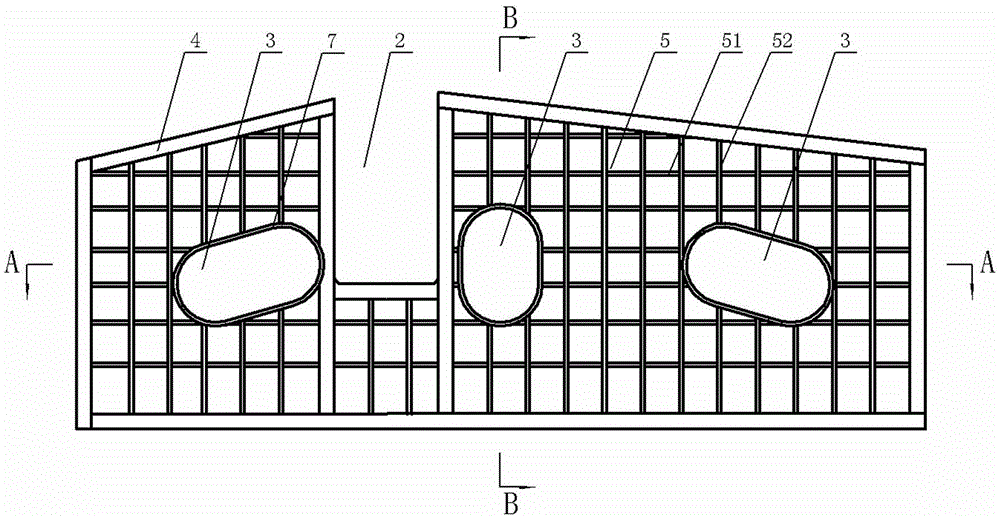

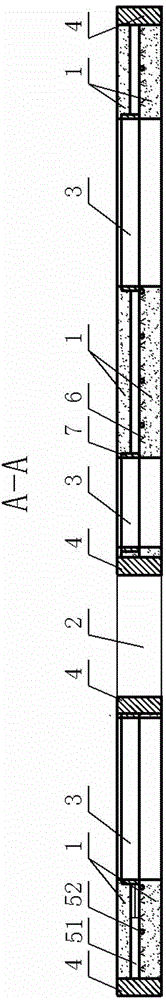

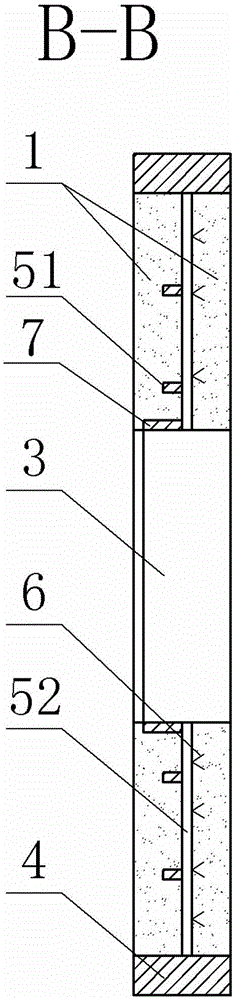

[0030] Embodiment one: if figure 1 As shown, the light-weight and long-life tundish cover in this embodiment includes a steel structure, a filling layer of refractory material 1, a slag hole 2 and a stopper hole 3, and the steel structure includes a stainless steel frame 4 and a stainless steel frame. Stainless steel mesh 5, the lower side of the stainless steel mesh 5 is evenly connected with anchors 6, the middle part of one side of the stainless steel mesh 5 is provided with a slag hole 2, and the outer edge of the slag hole 2 is provided with a stainless steel frame 7 , the stainless steel mesh 5 is also provided with some stopper holes 3, the outer edge of the stopper hole 3 is provided with a stainless steel frame 7, and the stopper hole 3 can be used as an observation hole and a temperature measurement hole at the same time, so The upper side and the lower side of the stainless steel mesh 5 are filled layers 1 of light refractory materials.

[0031] The stainless stee...

Embodiment 2

[0038] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference lies in: the stainless steel surface of the stainless steel mesh 5 is evenly wrapped with a buffer film.

Embodiment 3

[0039] Embodiment 3: Embodiment 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that stainless steel seamless steel pipes are also preset inside the tundish cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com