Method for modifying fast-crystallization high-crystallinity polylactic acid

A high-crystallinity, polylactic acid technology, applied in the field of rapid crystallization high-crystallinity polylactic acid modification, can solve the problems of high production cost, reduced production efficiency, low effect, etc., and achieves low reaction conditions, high crystallinity, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

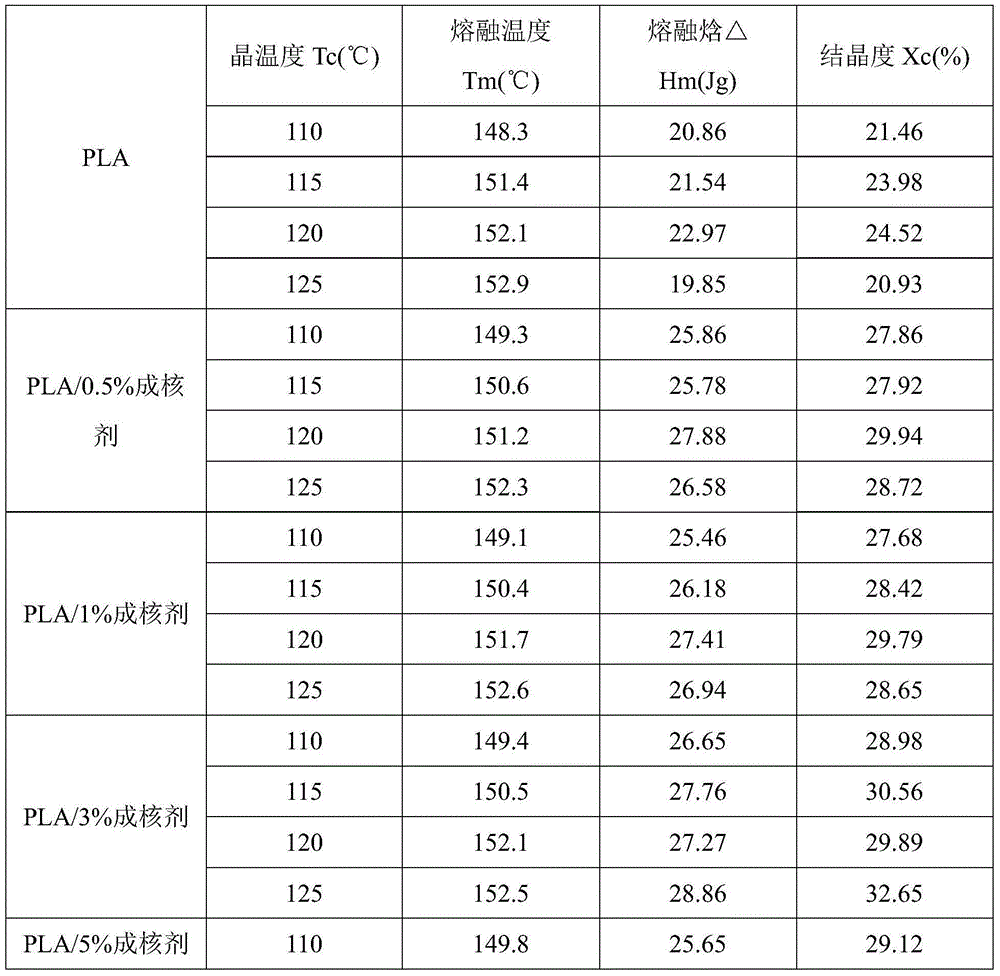

Embodiment 1

[0019] Dissolve 5g of phenylphosphoric acid in 200ml of water, an equivalent of magnesium chloride (MgCl 2 ) was dissolved in 100ml of water and added to the phenylphosphoric acid solution, fully stirred evenly. Then neutralize with 0.1mol / L sodium hydroxide solution to make the pH value of the solution about 5. After the precipitate was washed and filtered with suction, it was stirred at a constant temperature of 30°C for 24 hours to improve the crystallinity. The precipitate was repeatedly washed and filtered, fully dried and dehydrated, and sealed for storage.

[0020] The polylactic acid and the nucleating agent were dried, and the 100:0.5 raw material was added to the HAAKE torque rheometer, the blending temperature was 160°C, the blending time was 5min, and the rotation speed was 30r / min to obtain the modified polylactic acid. Store in a dry dish.

Embodiment 2

[0022] Dissolve 5g of phenylphosphoric acid in 200ml of water, an equivalent of zinc chloride (ZnCl 2 ) was dissolved in 100ml of water and added to the phenylphosphoric acid solution, fully stirred evenly. Then neutralize with 0.1mol / L potassium hydroxide solution to make the pH value of the solution about 5. After the precipitate was washed and filtered with suction, it was stirred at a constant temperature of 40° C. for 24 hours to improve the crystallinity. The precipitate was repeatedly washed and filtered, fully dried and dehydrated, and sealed for storage.

[0023] Polylactic acid and nucleating agent were dried, and 100:1 raw materials were added to the HAAKE torque rheometer, the blending temperature was 170°C, the blending time was 7min, and the rotation speed was 40r / min to obtain modified polylactic acid. Store in a dry dish.

Embodiment 3

[0025] Dissolve 5g of phenylphosphoric acid in 200ml of water, an equivalent of aluminum chloride (AlCl 3 ) was dissolved in 100ml of water and added to the phenylphosphoric acid solution, fully stirred evenly. Then neutralize with 0.1mol / L ammonia solution to make the pH value of the solution about 6. After the precipitate was washed and filtered with suction, it was stirred at a constant temperature of 50° C. for 72 hours to improve the crystallinity. The precipitate was repeatedly washed and filtered, fully dried and dehydrated, and sealed for storage.

[0026] The polylactic acid and the nucleating agent were dried, and the 100:3 raw material was added to the HAAKE torque rheometer, the blending temperature was 180°C, the blending time was 9min, and the rotational speed was 50r / min to obtain the modified polylactic acid. Store in a dry dish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com