Expandable polystyrene fireproof plate

The technology of expandable polystyrene and fireproof board is applied in the field of expandable polystyrene fireproof board, which can solve the problem that the flame retardant is easy to fall off, the flame retardant effect is low, and the fireproof effect of the expandable polystyrene is not ideal. And other problems, to achieve the effect of good waterproof, improve fire performance, increase fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

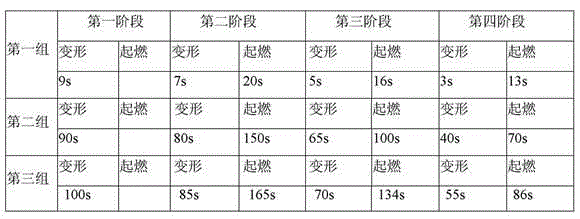

Embodiment 1

[0015] Example 1: An expandable polystyrene fireproof board, the fireproof board is pre-expanded by steam from expandable polystyrene raw material particles, and the internal flame retardant and the cured expandable polystyrene The granules are mixed evenly according to the weight ratio of 46:10, dried, then injected with steam, then put into the drying room for drying, and after cooling, apply external flame retardant on the surface of the board according to the following steps.

[0016] (1) Preliminary equipment maintenance and inspection:

[0017] A) Check whether the ultrasonic mixer is normal; pour clean water into the ultrasonic mixing chamber, then turn on the ultrasonic generator for 12 minutes, then observe whether the dirt or impurities adhering to the mixing chamber are removed; if it is cleared, replace it immediately or repair;

[0018] B) Remove impurities or dust in the mixing chamber of the ultrasonic mixer; after all the dirt or impurities have been separated...

Embodiment 2

[0026] Example 2: An expandable polystyrene fireproof board. The fireproof board is pre-expanded by steam from expandable polystyrene raw material particles, and the internal flame retardant and the cured expandable polystyrene are combined with ultrasonic waves. The particles are mixed evenly according to the weight ratio of 53:10, dried, then injected with steam, then put into the drying room for drying, and after cooling, apply external flame retardant on the surface of the board according to the following steps.

[0027] (1) Preliminary equipment maintenance and inspection:

[0028] A) Check whether the ultrasonic mixer is normal; pour clean water into the ultrasonic mixing chamber, then turn on the ultrasonic generator for 12 minutes, then observe whether the dirt or impurities adhering to the mixing chamber are removed; if it is cleared, replace it immediately or repair;

[0029] B) Remove impurities or dust in the mixing chamber of the ultrasonic mixer; after all the d...

Embodiment 3

[0037] Example 3: An expandable polystyrene fireproof board. The fireproof board is pre-expanded by steam from expandable polystyrene raw material particles, and the internal flame retardant and the cured expandable polystyrene are combined with ultrasonic waves. The particles are mixed evenly according to the weight ratio of 61:10, dried, then injected with steam, then put into the drying room for drying, and after cooling, apply external flame retardant on the surface of the board according to the following steps.

[0038] (1) Preliminary equipment maintenance and inspection:

[0039] A) Check whether the ultrasonic mixer is normal; pour clean water into the ultrasonic mixing chamber, then turn on the ultrasonic generator for 12 minutes, then observe whether the dirt or impurities adhering to the mixing chamber are removed; if it is cleared, replace it immediately or repair;

[0040] B) Remove impurities or dust in the mixing chamber of the ultrasonic mixer; after all the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com