Heat transfer compounding integrated furnace for biomass burning

A biomass and heat composite technology, applied in the direction of combustion ignition, combustion method, combustion equipment, etc., can solve the problems of unstable combustion, inconvenient ignition, increased work cost, etc. Difficulty, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

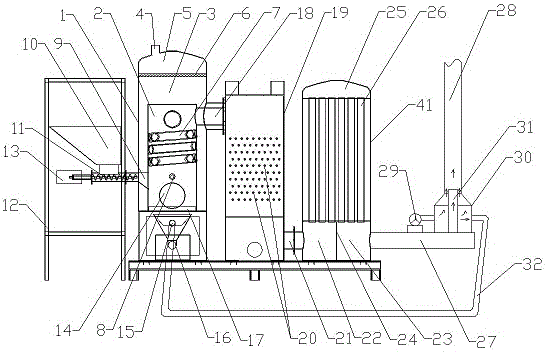

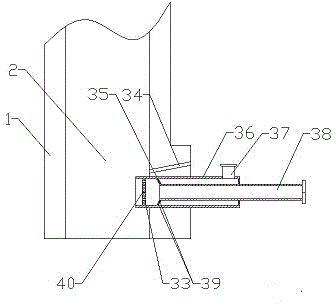

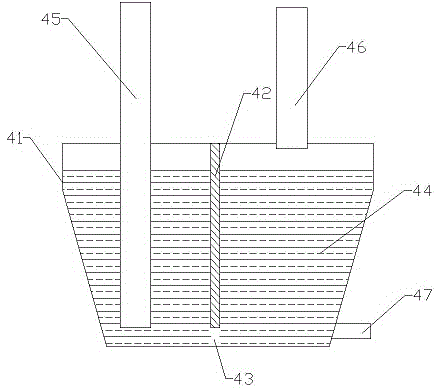

[0048] Examples such as figure 1 As shown, a biomass combustion and heat exchange composite integrated furnace includes a steam boiler, the exhaust pipe of the steam boiler is connected with a hot blast stove and a water heater in sequence, and the hot water heater is connected with flue gas discharge and smoke Gas waste heat recovery and utilization device. The steam boiler is also connected with a biomass feeding device.

[0049] The steam boiler includes a furnace body 1, a furnace 2 is installed in the furnace body 1, a steam-water separator 6 is installed near the upper end in the furnace body 1, and the steam-water separator 6 separates the inner chamber of the furnace into water Chamber 3 and steam chamber 5, the top of the furnace body 1 is provided with a steam outlet 4 communicating with the steam chamber 5.

[0050] The steam outlet 4 can communicate with all mechanical equipment using steam as a heating source.

[0051] The bottom of the furnace 2 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com