Pulverized coal flame burning diagnosis testing device

A technology of flame combustion and diagnostic test, which is applied in the direction of chemical analysis, fluorescence/phosphorescence, material excitation analysis, etc. using combustion, which can solve the problem of inability to simulate the combustion environment of pulverized coal, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

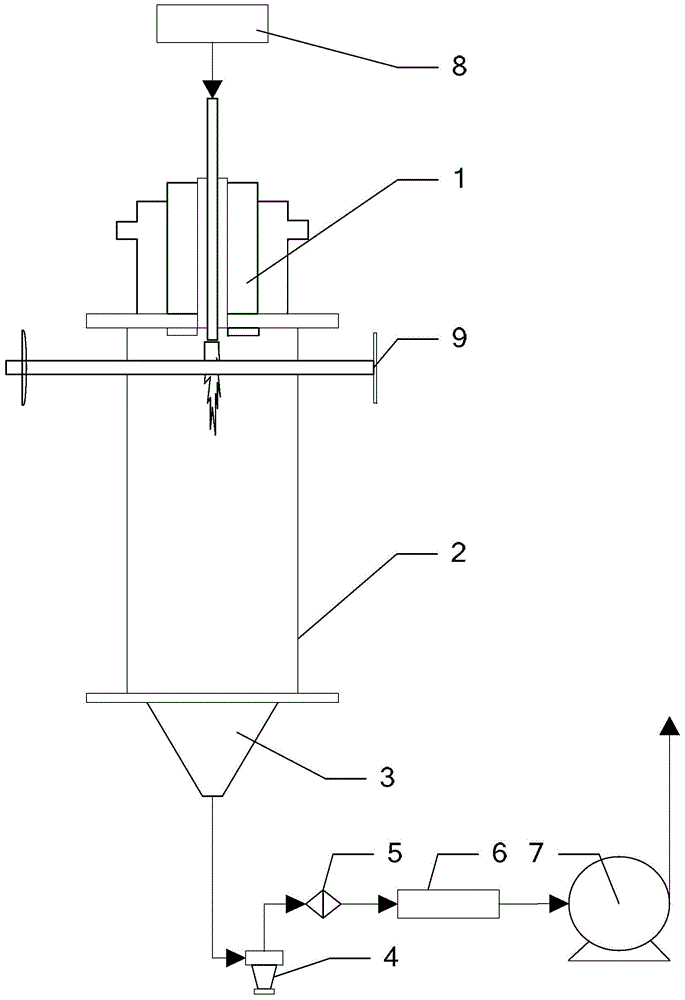

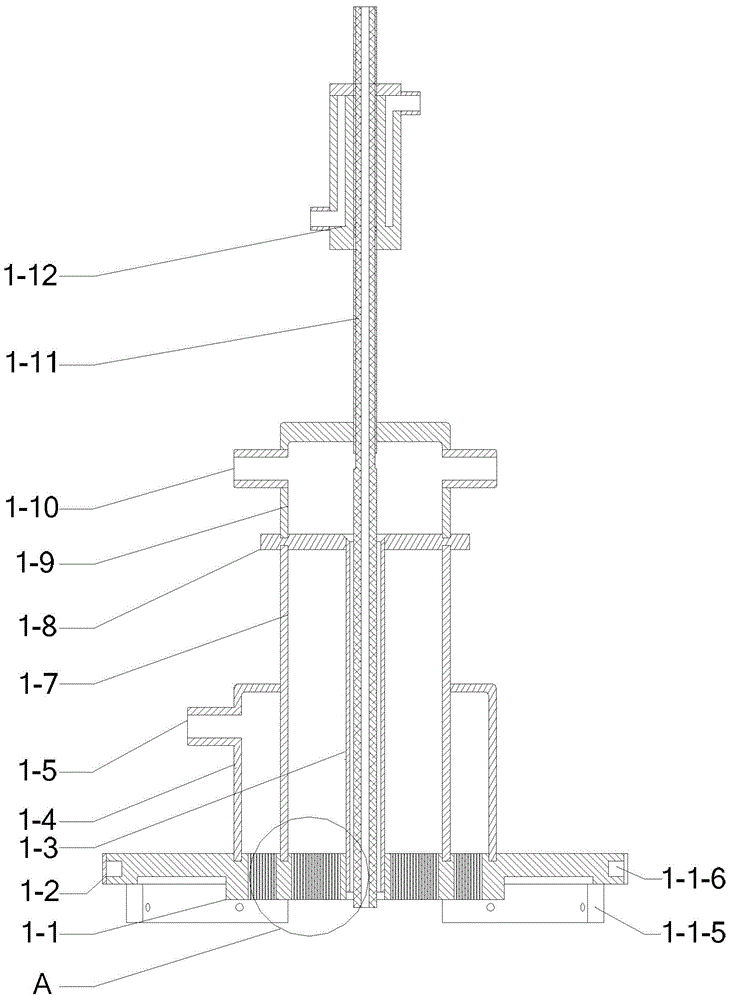

[0032] Specific implementation mode one: refer to Figure 1 to Figure 6 , Figure 9 Specifically illustrate the present embodiment, the pulverized coal flame combustion diagnostic test device described in the present embodiment, it comprises: integrated burner 1, 4 square optical windows 2, tail gas collecting device 3, cyclone separator 4, filter 5, drying Device 6, induced draft fan 7, micro powder feeder 8 and PLIF optical path system 9;

[0033] The space surrounded by 4 square optical windows 2 end to end is used as the combustion chamber of the pulverized coal flame combustion diagnostic test device, and the space is a transparent cube from top to bottom;

[0034]The powder outlet of the micro-powder feeder 8 is connected to the powder inlet end of the integrated burner 1, the flame injection end of the integrated burner 1 is connected to the upper port of the combustion chamber, and the lower port of the combustion chamber is connected to the intake port of the exhaust...

specific Embodiment approach 2

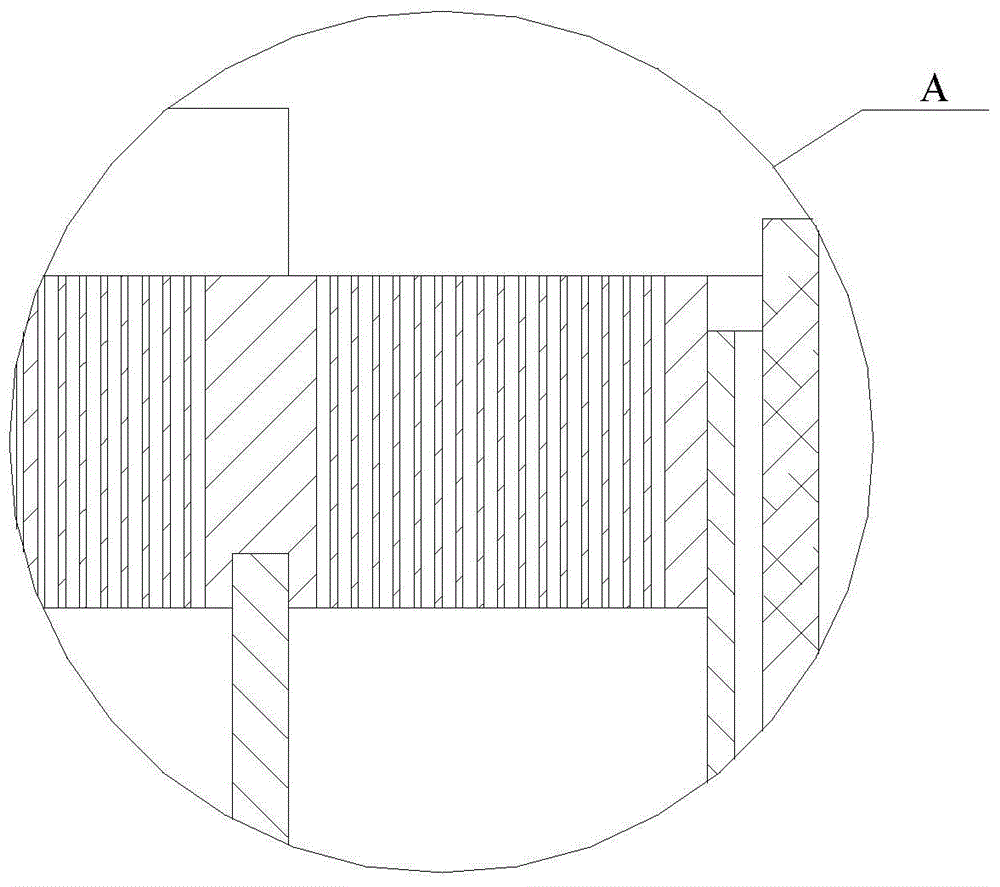

[0054] Specific embodiment two: This embodiment is to further explain the pulverized coal flame combustion diagnostic test device described in specific embodiment one. In this embodiment, the integrated burner 1 also includes: a powder feeding pipe water cooling device 1-12, the The powder feeding pipe water cooling device 1-12 is used for cooling the powder feeding pipe 1-11.

[0055] The powder feeding pipe 1-11 is cooled by the cold air of the secondary air pipe 1-3 and the powder feeding pipe water cooling device 1-12 at the same time, and the temperature balance is maintained during the test.

specific Embodiment approach 3

[0056] Specific implementation mode three: refer to Figure 7 with Figure 8 This embodiment is specifically described. This embodiment is to further illustrate the pulverized coal flame combustion diagnostic test device described in Embodiment 1. In this embodiment, the center of the main body 3-1 of the exhaust gas collection device 3 has a conical through hole , the wide mouth of the conical through hole is the air inlet of the exhaust gas collection device 3, the narrow mouth of the conical through hole is the gas outlet of the exhaust gas collection device 3, and the side wall of the main body 3-1 near the air inlet has a cooling ring. Groove 3-6, the periphery of the cooling groove 3-6 is wrapped with a cooling groove sealing skin 3-2, and the cooling groove sealing skin 3-2 is provided with a through hole 3-3,

[0057] Four arc-shaped connecting pieces (3-7) are arranged around the air inlet of the exhaust gas collection device 3, and each arc-shaped connecting piece (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com