A kind of manufacturing method of anti-blue light resin lens

A technology of resin lens and manufacturing method, which is applied in optics, optical components, instruments, etc., can solve problems such as attenuation of blue light, decreased vision, and blurred vision, and achieve the effect of improved anti-blue light ability, unique technology, and novel creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

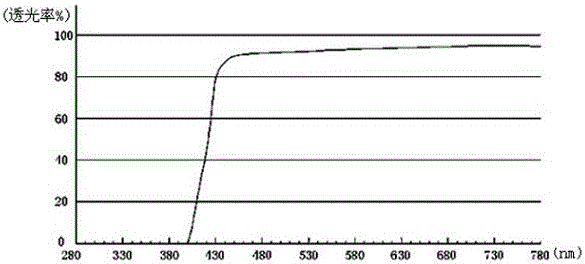

[0033] a. to combine figure 1 , according to the addition amount of 0.01%, weigh 20 grams of blue light wavelength conversion particle powder with a particle size of 5-15 microns, grind it in a high-energy planetary nano ball mill for 30 minutes to 2 hours, and pulverize the particle size into a blue light wavelength of 2-20 nanometers. convert particles for use;

[0034] b. Use a plastic container to measure 20 liters of silica resin lens plus hard liquid, insert the stirring head of a high-speed electric mixer into the liquid, and vigorously stir at 1800 revolutions per minute for 30 minutes. During the stirring process, add 0.01% (2 grams) of Nano-scale blue light wavelength conversion particle powder, until the conversion particles are all uniformly dispersed in the silica plus hard liquid;

[0035] c. Pour the silica plus hard liquid mixed with blue light wavelength conversion particles into the stainless steel tank of a 200-watt ultrasonic oscillator for ultrasonic disp...

Embodiment 2

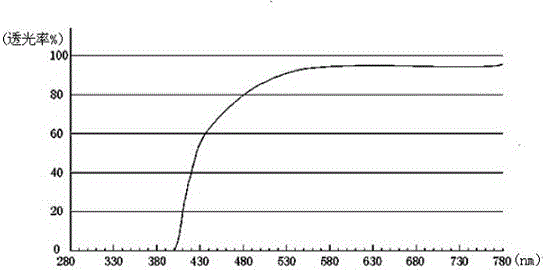

[0041] a. to combine figure 2 , according to the addition amount of 0.02% (4 grams), weigh 20 grams of blue light wavelength conversion particle powder with a particle size of 5-15 microns, grind it in a high-energy planetary nano-ball mill for 30 minutes to 2 hours, and pulverize the particle size into 2-20 The blue light wavelength conversion particles of nanometers are for use; the b-f process method sequence is the same as that of the first embodiment, and will not be repeated.

Embodiment 3

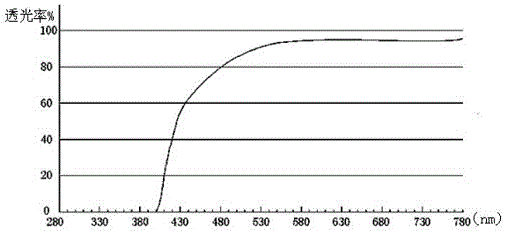

[0043] a. to combine image 3 , according to the addition amount of 0.03% (6 grams), weigh 20 grams of blue light wavelength conversion particle powder with a particle size of 5-15 microns, grind it in a high-energy planetary nano-ball mill for 30 minutes to 2 hours, and pulverize the particle size into 2-20 The nanometer blue light wavelength conversion particles are for use; the b-f process sequence is the same as that of the first embodiment, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com