Coloring composition, coloring cured film and display device

A technology for coloring compositions and colorants, which can be used in optics, optomechanical equipment, instruments, etc., and can solve problems such as heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0279] Hereinafter, an Example is given and the embodiment of this invention is demonstrated further concretely. However, the present invention is not limited to the following examples.

[0280]

Synthetic example 1

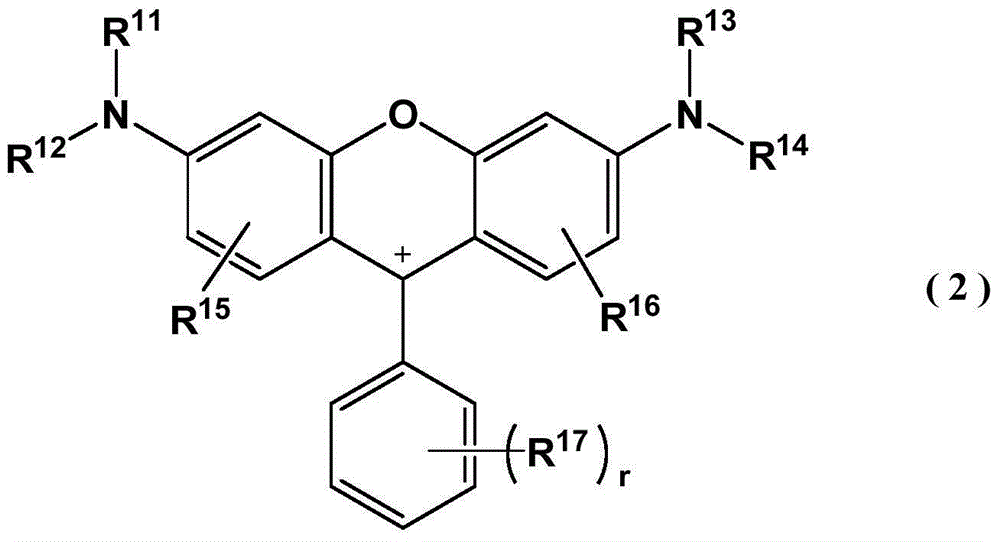

[0282] A 100mL three-neck flask with a stirring bar, a reflux cooling tube, and a thermometer is fully replaced with nitrogen, and 15.0g of cyclohexanone is charged, and heated to an internal temperature of 80±2°C under nitrogen flow. On the other hand, 4.00 g of the dye monomer (A1) shown below, 0.50 g of the dye monomer (A3) shown below, 6.00 g of methyl methacrylate, and 4.50 g of methyl Acrylic acid, 2.18 g of 2,2'-azobis(2,4-dimethylvaleronitrile) (manufactured by Wako Pure Chemical Industries, Ltd., trade name V-65) as a polymerization initiator, 45.0 g of cyclohexanone The prepared solution was maintained at an internal temperature of 80±2° C., and was added dropwise over 2 hours using a pump. After completion of the dropwise addition, stirring was continued at this temperature for another 1 hour. Thereafter, the reaction solution was cooled to room temperature and added dropwise to a large amount of hexane. The obtained colored solid was dried under reduced pressure ...

Synthetic example 2~10

[0285] In Synthesis Example 1, polymers (2) to (10) were obtained in the same manner as Synthesis Example 1 except that the type and amount of monomers used for polymerization were changed as shown in Table 1. The structures of the dye monomers (A1) to (A4) are as above. Polymers (2) to (4) and polymers (9) to (10) correspond to polymer (A1). Polymers (5) to (8) are not polymer (A1).

[0286]

[0287] The symbols used in Table 1 are as follows.

[0288] MMA: methyl methacrylate

[0289] MA: methacrylic acid

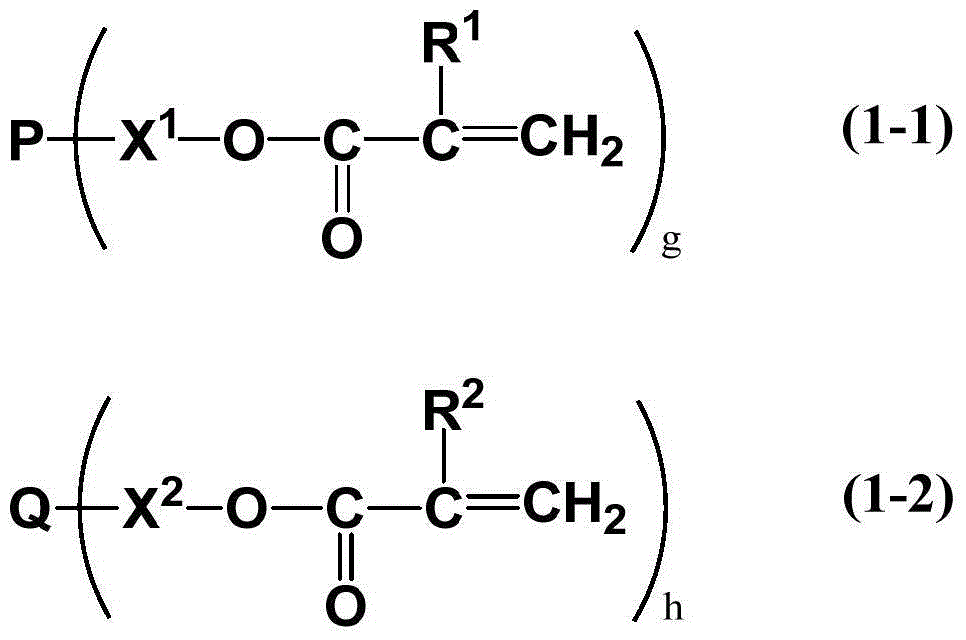

[0290] In addition, "p / q" in Table 1 indicates that when the number of moles of the compound represented by the formula (1-1) used for polymerization is p, and the number of moles of the compound represented by the formula (1-2) is represented by q molar ratio.

[0291] In addition, the dye monomers (A1) to (A4) were synthesized with reference to the following publications, respectively.

[0292] Dye monomer (A1): synthesized according to Synthesis Example 2 desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap