A floating vibrator ultrasonic salt bath compound cleaning machine and its use method

A salt-bath compounding and washing machine technology, applied in the field of washing machines, can solve the problems of consuming a lot of manpower, material and financial resources, heating pipe rupture, heating pipe damage, etc., to improve space utilization, reduce water consumption, and reduce heating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

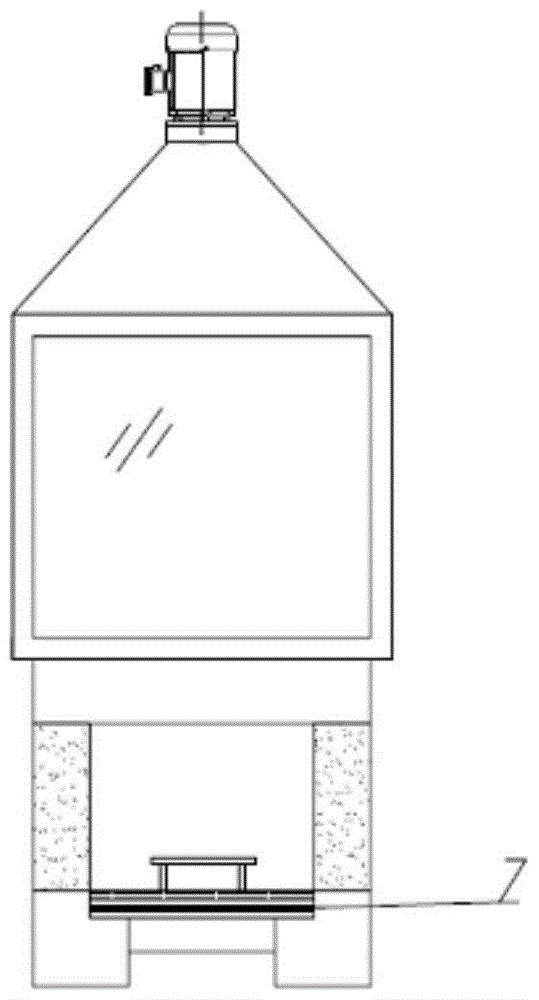

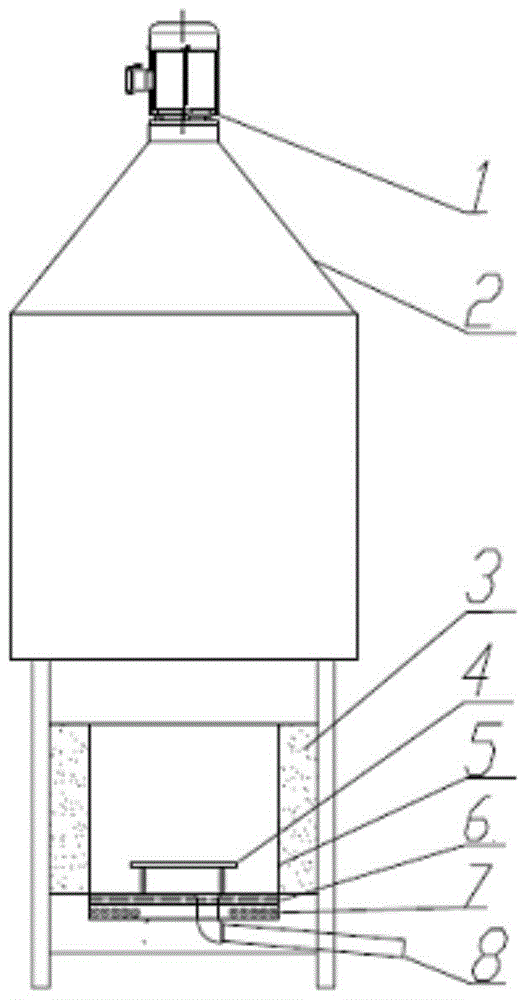

[0041] like Figure 1-4 As shown, a floating vibrator ultrasonic salt bath composite cleaning machine includes a closed frame, and a heat-insulating fan 1 is arranged on the upper end of the frame. frame connection; the middle of the frame is cuboid, the size of the middle part of the frame is greater than the position of the bottom, an observation window is set in the middle of the frame, and a cuboid cleaning tank 5 is set at the bottom of the frame, and the top of the cleaning tank The vibrator board is arranged, and the ultrasonic vibrator is arranged on the vibrator board. When in use, the head of the ultrasonic vibrator is immersed in the liquid in the cleaning tank, the width of the lower part of the rack is smaller than the width of the middle part, and a workbench 4 is horizontally set at the bottom of the cleaning tank 5 , a support plate for supporting the cleaning tank is set below the workbench 4, the support plate is a ceramic glass plate 6, and a heating coil 7 ...

Embodiment 2

[0048] A floating vibrator ultrasonic salt bath composite cleaning machine, comprising a closed frame, on the upper end of the frame is provided a heat-insulating fan 1, and the heat-insulating fan 1 is connected to the frame through an inverted frustum-shaped protective cover 2; The middle of the rack is in the shape of a cuboid, the size of the middle part of the rack is larger than that of the lower part, an observation window is set in the middle of the rack, a cuboid cleaning tank is set in the lower part of the rack, and a vibrator plate is set on the top of the cleaning tank. An ultrasonic vibrator is arranged on the vibrator plate. When in use, the head of the ultrasonic vibrator is immersed in the liquid in the cleaning tank. A plurality of workbenches are horizontally arranged at the bottom of the wash tank. A certain distance; a support plate for supporting the cleaning tank is set under the workbench, the support plate is a ceramic glass plate, and a heating coil us...

Embodiment 3

[0051] A floating vibrator ultrasonic salt bath composite cleaning machine, comprising a closed frame, on the upper end of the frame is provided a heat-insulating fan 1, and the heat-insulating fan 1 is connected to the frame through an inverted frustum-shaped protective cover 2; The middle of the frame is cuboid, the size of the middle part of the frame is greater than the position of the lower part, an observation window is set in the middle of the frame, and a plurality of parallel cleaning tanks 5 that are all in a rectangular parallelepiped shape are vertically set at the lower part of the frame. A vibrator plate is arranged on the top of the cleaning tank, and an ultrasonic vibrator is arranged on the vibrator plate. When in use, the head of the ultrasonic vibrator is immersed in the liquid in the cleaning tank, and a workbench 4 is horizontally set at the bottom of each cleaning tank 5. A support plate for supporting the cleaning tank is arranged under the workbench 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com