Sludge drying incineration system and method

A sludge drying and sludge technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of poor economic feasibility and high cost of sludge incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (Example 1, sludge drying and incineration system)

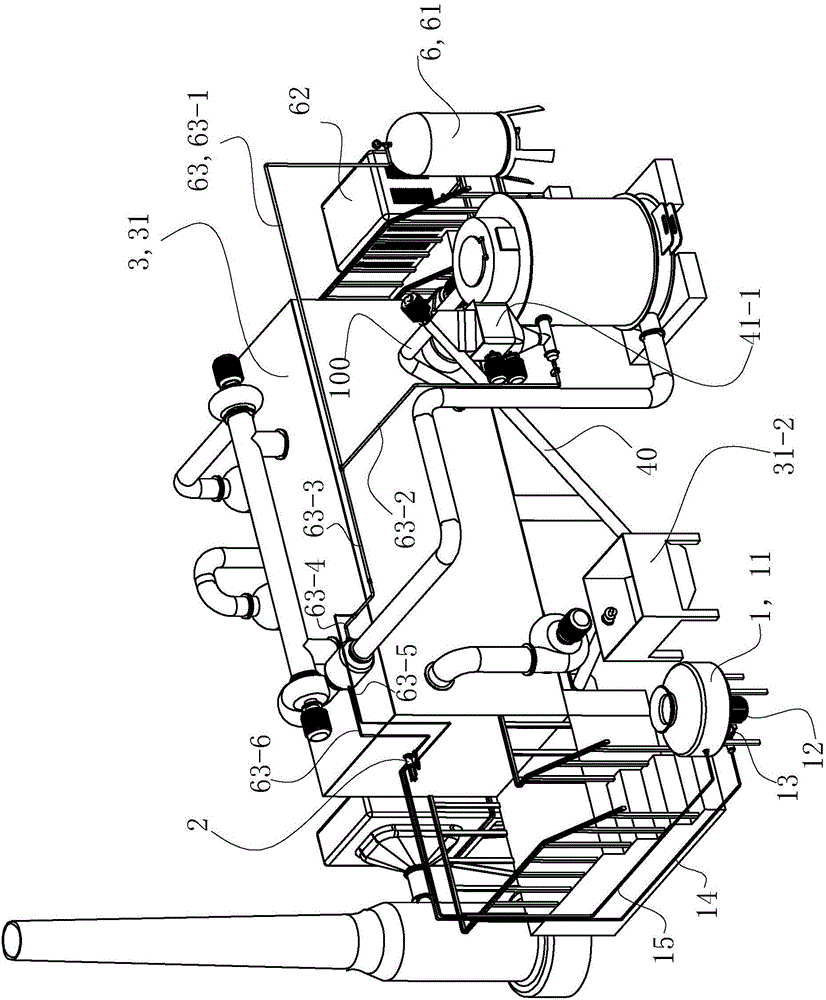

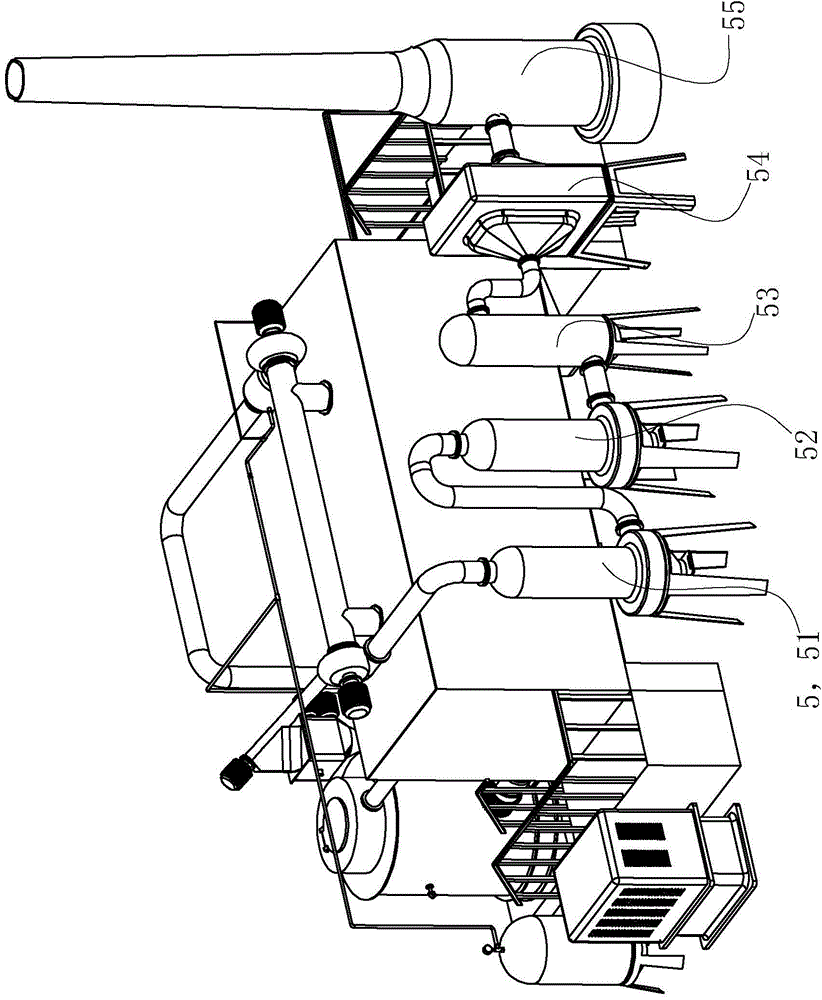

[0064] See figure 1 , The sludge drying and incineration system in this embodiment includes a wet sludge storage tank 1 , a sludge high-pressure injection device 2 , a drying device 3 , an incineration device 4 , a flue gas purification device 5 and an air supply device 6 .

[0065]The wet sludge storage tank 1 includes a tank body 11 , a stirring motor 12 , stirring paddles, a sludge pump 13 , a sludge feeding pipeline 14 and a sludge return pipeline 15 . Stirring motor 12 is arranged on the bottom outside of tank body 11, and the motor shaft of stirring motor 12 stretches into the inner chamber of tank body 11 from bottom to top, and motor shaft is connected with the stirring paddle inside tank body 11, drives stirring paddle to rotate. Sludge pump 13 is arranged on the bottom outside of tank body 11, and the mud inlet of sludge pump 13 is connected with the mud outlet of tank body 11 bottoms, and the mud outlet of...

Embodiment 2

[0096] (Example 2, sludge drying and incineration method)

[0097] The sludge drying and incineration method of this embodiment uses the sludge drying and incineration system described in Example 1, comprising the following steps:

[0098] ① Transport the sludge with a water content of 75% to 85% produced by the urban sewage treatment plant into the tank body 11 of the wet sludge storage tank 1, turn on the stirring motor 12 to stir the wet sludge evenly, and then turn on the sludge pump 13 The wet sludge is sent from the tank body 11 into the sludge high-pressure injection device 2 .

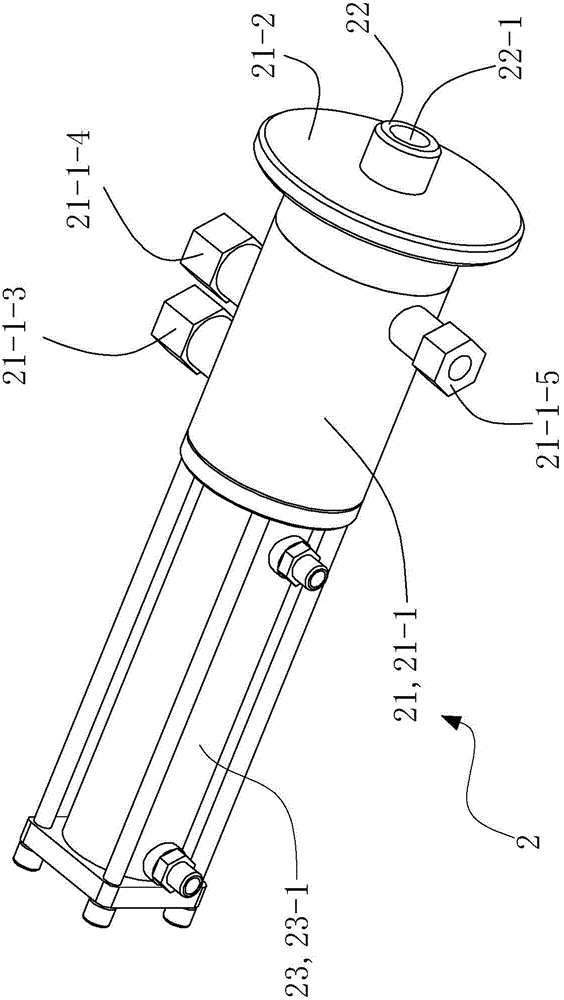

[0099]The wet sludge enters the sludge chamber 21-1a from the mud inlet 21-1-3 of the cylinder body 21-1 of the nozzle seat assembly 21, and then enters the sludge passage 22-1 of the nozzle 22, and the air compressor is turned on to pump the sludge to the cylinder. The air inlet 21-1-5 of the body 21-1 is fed with high-pressure hot air, and the negative pressure generated at this time will ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com