Method for purifying vindesine

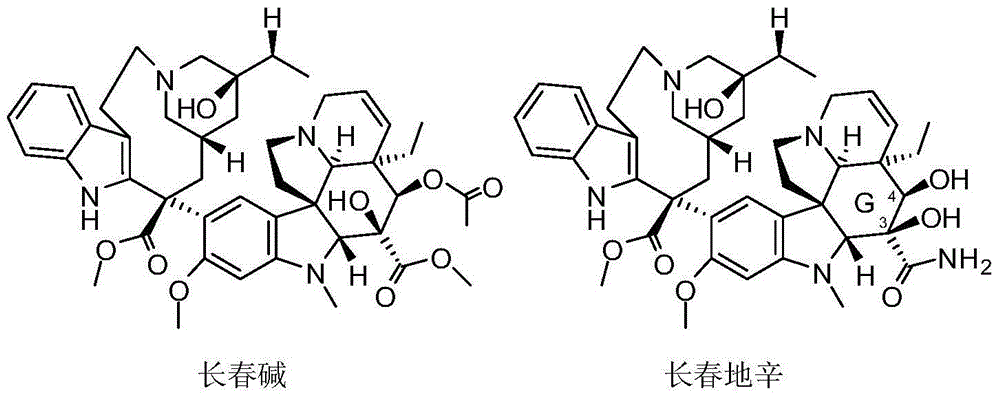

A purification method, the technology of vindesine, which is applied in the direction of organic chemistry, can solve the problems of complicated process and low purification efficiency of vindesine, and achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 5.98kg of 300-mesh silica gel, add chloroform and stir to remove the air bubbles in the silica gel, and then evenly load the silica gel into the preparative chromatography. The column size is Φ20cm×52cm. After the stationary phase silica gel is compacted, rinse with the eluent 2h, to obtain the preparative chromatographic column packed;

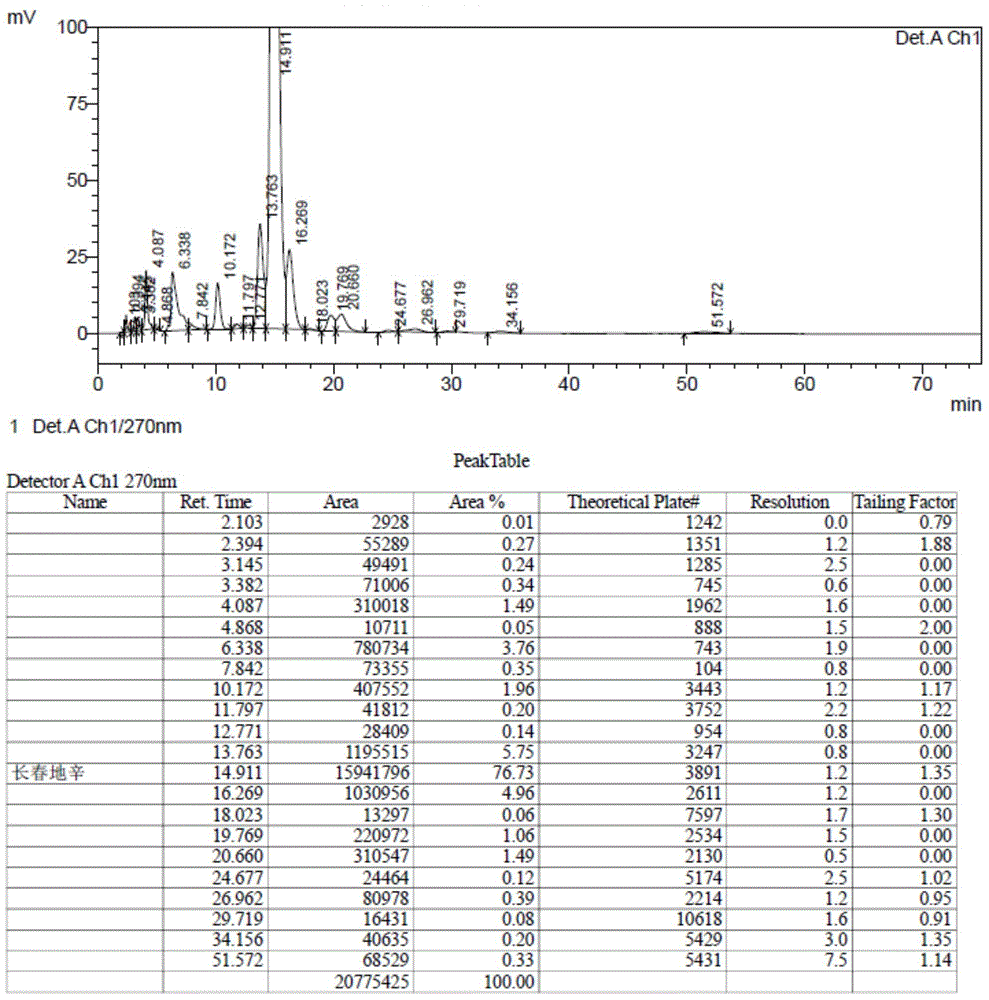

[0027] 2) Dissolve 195g of Vindesin crude product (purity is 76.73%) in chloroform, feed, feed amount is 300ml;

[0028] 3) Use a constant pressure and constant flow pump to enter the eluent, first use chloroform: methanol = 90: 1 solvent to elute 2 bed layers, then use chloroform: methanol = 40: 1 solvent to elute 3 bed layers and collect the elution Solution a, then use chloroform:methanol=30:1 solvent to elute the 4 bed layers and collect eluent b, and finally replace it with chloroform:methanol=15:1 eluent to elute the residue in the prepared chromatographic column;

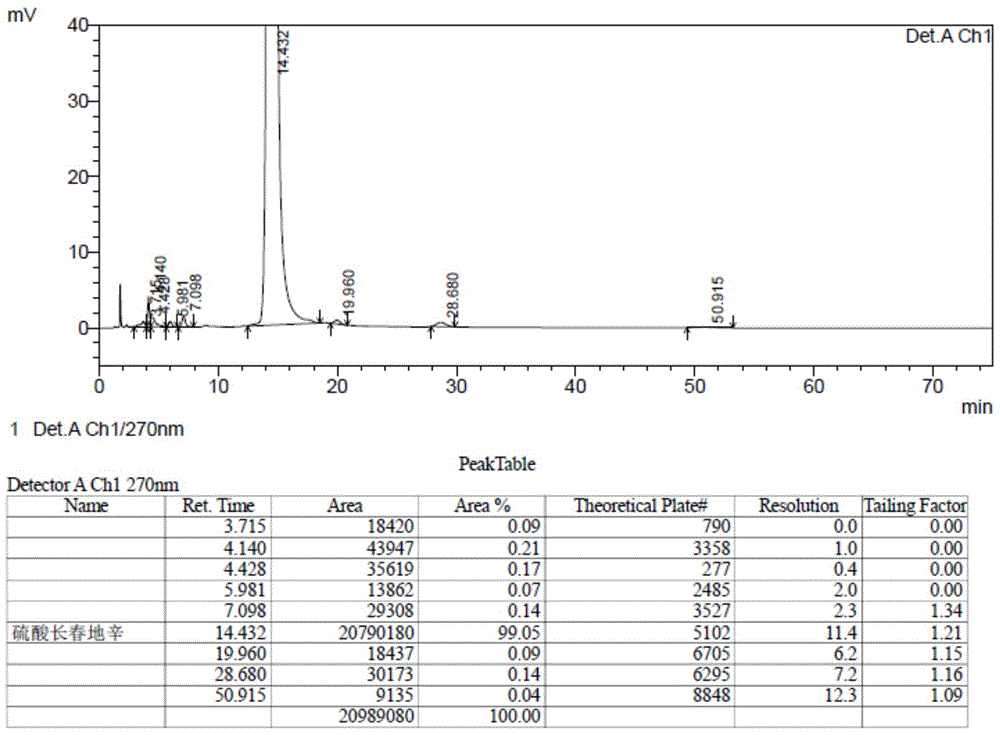

[0029] 4) The eluent b was recovered under reduced pre...

Embodiment 2

[0032] 1) Weigh 6.10kg of 400-mesh silica gel, add chloroform and stir to remove the air bubbles in the silica gel, and then evenly load the silica gel into the preparative chromatography. The column size is Φ20cm×52cm. After the stationary phase silica gel is compacted, rinse with the eluent 2h, to obtain the preparative chromatographic column packed;

[0033] 2) Dissolve 205g of Vindesin crude product (purity is 72.19%) in chloroform, feed, feed amount is 320ml;

[0034] 3) Use a constant pressure and constant flow pump to enter the eluent, first use chloroform:methanol=95:1 solvent to elute 2 bed layers, then use chloroform:methanol=45:1 solvent to elute 3 bed layers and collect the elution solution a, then use chloroform:methanol=35:1 solvent to elute 4 bed layers and collect eluent b, and finally use chloroform:methanol=15:1 eluent to elute the residue in the prepared chromatographic column;

[0035] 4) The eluent b was recovered under reduced pressure to obtain 94.5 g o...

Embodiment 3

[0037] 1) Weigh 6.00kg of 200-mesh silica gel, add chloroform and stir to remove the air bubbles in the silica gel, and then evenly load the silica gel into the preparative chromatography. The column size is Φ20cm×52cm. After the stationary phase silica gel is compacted, rinse with the eluent 2h, to obtain the preparative chromatographic column packed;

[0038] 2) Dissolve 165g of Vindesin crude product (purity: 58.97%) in chloroform, feed, feed amount is 280ml;

[0039] 3) Use a constant pressure and constant flow pump to enter the eluent, first use chloroform: methanol = 90: 1 solvent to elute the 3 beds, then use chloroform: methanol = 40: 1 solvent to elute the 3 beds and collect the elution solution a, and then use chloroform:methanol=30:1 solvent to elute the 4 bed layers and collect the eluent b, and finally replace it with chloroform:methanol=10:1 eluent to elute the residue in the prepared chromatographic column;

[0040] 4) The eluent b was recovered under reduced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com