Heat-conduction electric-insulation rubber-plastic composite material and preparation method thereof

A heat-conducting insulating filler and composite material technology, applied in the chemical industry, can solve the problems of composite materials such as decreased mechanical properties and poor compatibility, and achieve the effects of improved mechanical properties, improved thermal conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

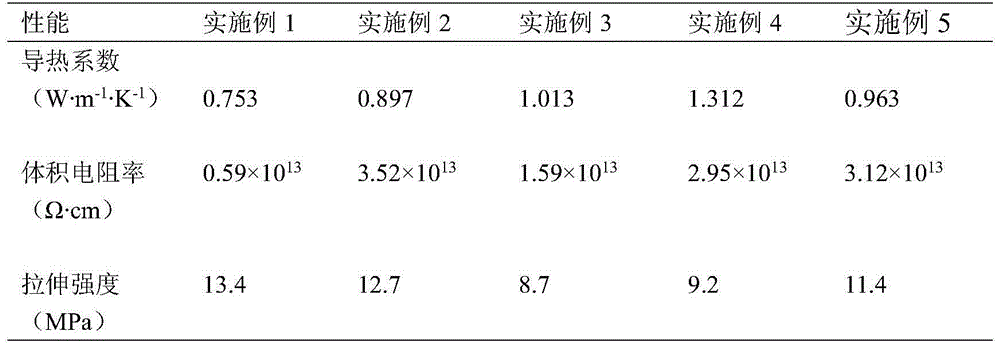

Examples

Embodiment 1

[0025] The preparation method of the thermally conductive and insulating rubber-plastic composite material in this embodiment is as follows:

[0026] (1) 0.5 gram of coupling agent (A-172) is dissolved in the ethanol-water solution of 75% ethanol mass fraction in 250ml, is mixed with coupling agent ethanol-water solution; °C, react in 250ml sodium hydroxide concentrated solution with a molar concentration of 2mol / L for 18h, then filter and dry. Then put in the coupling agent ethanol-water solution and react at 60° C. for 4 hours to obtain the aluminum nitride after grafting the coupling agent on the surface.

[0027] (2) After plasticizing 20 grams of natural rubber (NR) in the internal mixer for 20 minutes, add the aluminum nitride (AlN) obtained in (1) into the internal mixer and continue mixing for 10 minutes, and finally add 40 grams of EVA, 2 grams Antioxidant 1010 and 1 gram of vulcanizing agent (double 2.5) were placed in an internal mixer and mixed evenly, and then th...

Embodiment 2

[0029] The preparation method of the thermally conductive and insulating rubber-plastic composite material in this embodiment is as follows:

[0030] (1) 1.5 gram coupling agent (A-172) is dissolved in the ethanol mass fraction of 250ml and is in the ethanol-water solution of 85%, is mixed with coupling agent ethanol-water solution; React in 250ml of concentrated sodium hydroxide solution with a temperature of 100°C and a molar concentration of 2.5mol / L for 15 hours, then filter and dry. Then put in the coupling agent ethanol-water solution and react at 70° C. for 5 hours to obtain the hexagonal plate-shaped boron nitride grafted with the coupling agent on the surface.

[0031] (2) After plasticizing 60 grams of ethylene-propylene-diene rubber (EPDM) and silicone rubber (MVQ) in an internal mixer for 20 minutes, add the hexagonal flake boron nitride (h-BN) obtained in step (1) into the compact The mixer continued to mix for 10 minutes, and finally added 30 grams of polyethyle...

Embodiment 3

[0033] The preparation method of the thermally conductive and insulating rubber-plastic composite material in this embodiment is as follows:

[0034] (1) 3 gram coupling agents (A-172) are dissolved in the ethanol mass fraction of 250ml and be in the ethanol-water solution of 90%, be mixed with coupling agent ethanol-water solution; 50 gram hexagonal flake boron nitride (h -BN) and alumina (Al 2 o 3 ) was reacted in 250ml of concentrated sodium hydroxide solution with a temperature of 120°C and a molar concentration of 4mol / L for 18h in advance, then filtered and dried. Then put in the coupling agent ethanol-water solution and react at 80° C. for 4 hours to obtain the hexagonal plate-shaped boron nitride grafted with the coupling agent on the surface.

[0035] (2) After plasticizing 60 grams of methyl vinyl silicone rubber (MVQ) in the internal mixer for 25 minutes, add the hexagonal flake boron nitride (h-BN) obtained in (1) into the internal mixer and continue mixing for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com