Cracking preventing paint

An anti-cracking and paint technology, applied in the field of paint and coatings, can solve the problems of paint being exposed to water and easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

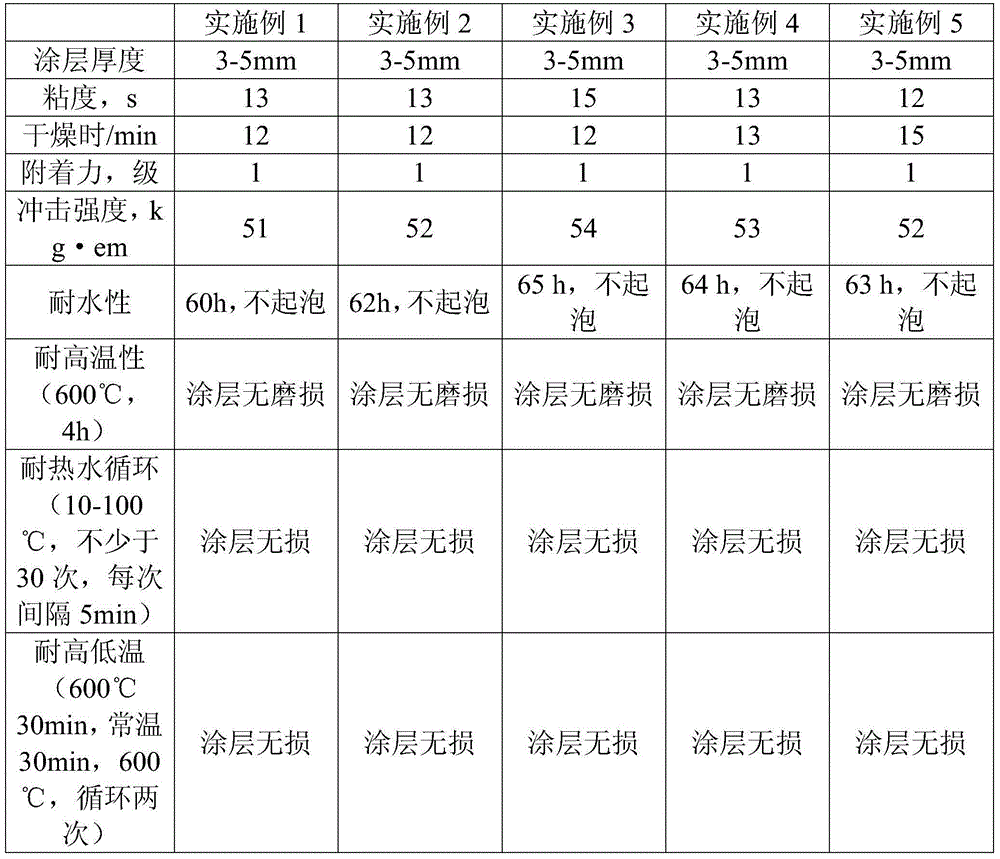

Examples

Embodiment 1

[0019] An anti-cracking paint, the composition of the mass parts of the anti-cracking paint is as follows: 20 parts of modified rosin resin, 15 parts of tung oil, 3.2 parts of epoxy resin coagulant, 12 parts of hydroxyl acrylic resin, 10 parts of glycerol, soybean plant Short oil alkyd resin 16 parts, defoamer 0.2 part, leveling agent 0.2 part, moistureproof agent 0.2 part.

[0020] Wherein, the modified rosin resin is a modified phenolic resin.

[0021] Wherein, the composition of mass parts of the defoamer is as follows: 10 parts of methacrylate polymer, 8 parts of aromatic hydrocarbon, 20 parts of cycloalkane, 50 parts of alkanes, and the carbon of the methacrylate polymer is Alkyl methacrylate with an atomic number of 1-20 is a constituent unit.

[0022] Wherein, the average molecular weight of the methacrylate polymer is 280,000-300,000.

[0023] Wherein, the composition of mass parts of the leveling agent is as follows: 6 parts of butyl acrylate, 3 parts of polyether m...

Embodiment 2

[0026] An anti-cracking paint, the composition of the mass parts of the anti-cracking paint is as follows: 22 parts of modified rosin resin, 16 parts of tung oil, 3.5 parts of epoxy resin coagulant, 13 parts of hydroxyl acrylic resin, 12 parts of glycerol, soybean plant 16.5 parts of short oil alkyd resin, 0.3 parts of defoaming agent, 0.3 parts of leveling agent, and 0.3 parts of moisture-proof agent.

[0027] Wherein, the modified rosin resin is a modified phenolic resin.

[0028] Wherein, the composition of the mass parts of the defoamer is as follows: 12 parts of methacrylate polymer, 10 parts of aromatic hydrocarbon, 24 parts of cycloalkane, 53 parts of alkanes, and the carbon of the methacrylate polymer is Alkyl methacrylate with an atomic number of 1-20 is a constituent unit.

[0029] Wherein, the average molecular weight of the methacrylate polymer is 300,000-350,000.

[0030] Wherein, the composition of mass parts of the leveling agent is as follows: 6.8 parts of bu...

Embodiment 3

[0033] An anti-cracking paint, the composition of the mass parts of the anti-cracking paint is as follows: 25 parts of modified rosin resins, 18 parts of tung oil, 4 parts of epoxy resin coagulants, 15 parts of hydroxyl acrylic resins, 12 parts of glycerol, soybean plant Short oil alkyd resin 17 parts, defoamer 0.5 part, leveling agent 0.5 part, moistureproof agent 0.4 part.

[0034] Wherein, the modified rosin resin is a modified phenolic resin.

[0035] Wherein, the composition of mass parts of the defoamer is as follows: 12 parts of methacrylate polymers, 10 parts of aromatic hydrocarbons, 25 parts of naphthenes, 60 parts of alkanes, and the carbon of the methacrylate polymers is Alkyl methacrylate with an atomic number of 1-20 is a constituent unit.

[0036] Wherein, the average molecular weight of the methacrylate polymer is 300,000-450,000.

[0037] Wherein, the composition of mass parts of the leveling agent is as follows: 7 parts of butyl acrylate, 6 parts of polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com